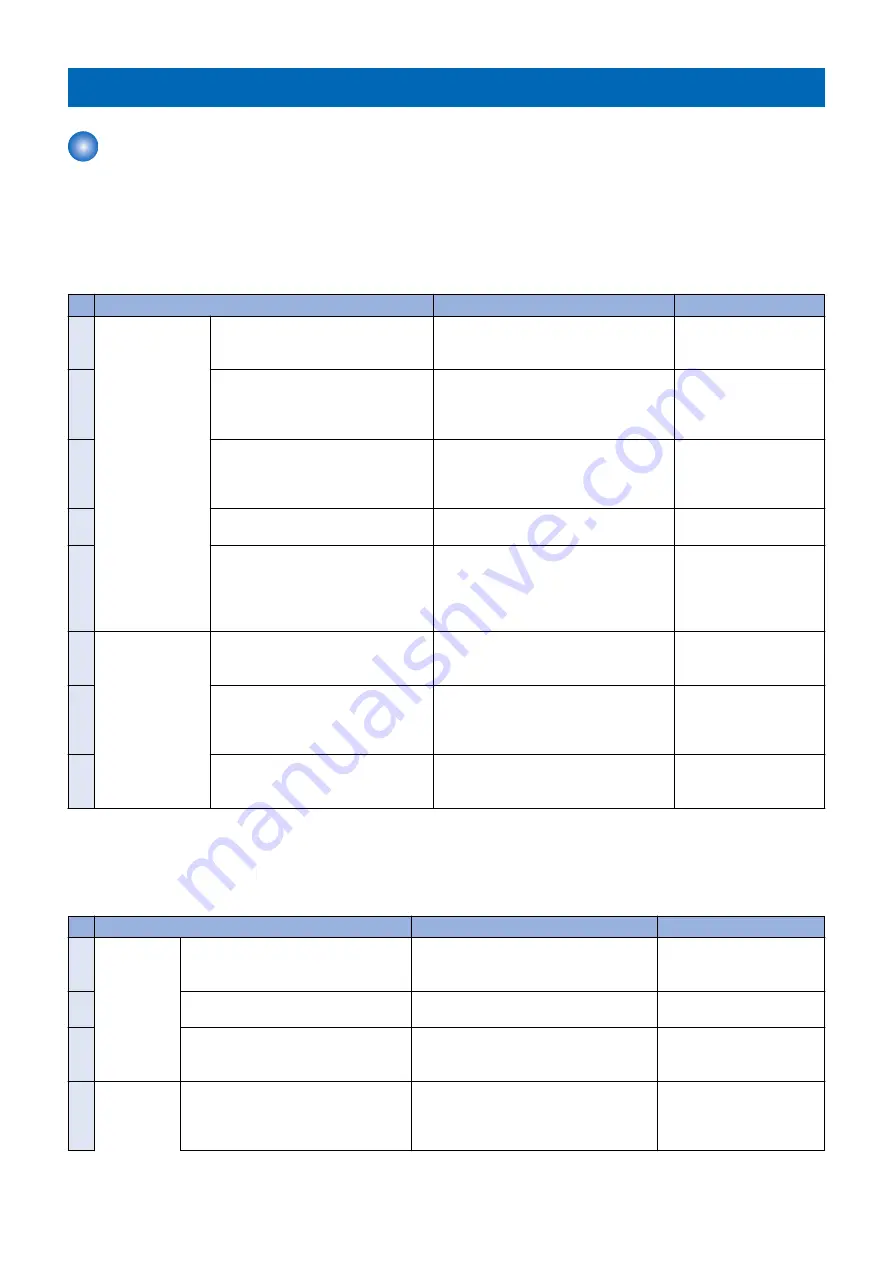

Basic Adjustment

Overview

The basic function of this finisher has 4 major functions : Paper Alignment, Staple Position, Fold Position, Saddle Stitch Position.

■ Adjusting the Processing Tray Area

In the case adjusting the processing tray area, adjust the paper alignment at first, and adjust the staple position.

In the case adjusting the paper alignment, adjust skew and transport direction at first, and adjust front

‐

rear direction.

No

Items

Use case

Refer to

1

Adjusting the Paper

Alignment

Adjusting Stacker Alignment Position

When misalignment occurs in front/rear di-

rection.

“Adjusting Stacker Align-

ment Position” on page

149

2

Adjusting Center Alignment Standard

Position

• When the standard position for the

center alignment is misaligned.

• When misalignment occurs in front/

rear direction.

“Adjusting Center Align-

ment Standard Position ”

on page 150

3

Right Angle Adjustment of Alignment

Plate

• When remove or replace the align-

ment plate.

• When the paper alignment position is

displaced.

“Right Angle Adjustment

of Alignment Plate ” on

page 151

4

Adjusting Delivery of Staple Stack

When the paper displacement occurs on

the 1st to 2nd sheets of buffered paper.

“Adjusting Delivery of Sta-

ple Stack ” on page 154

5

Adjusting the Return Roller/Swing Unit

Height

• When misalignment occurs in feed di-

rection.

• When misalignment occurs by failure

of the paper feeding to processing

tray.

“Adjusting the Return

Roller/Swing Unit Height ”

on page 155

6

Adjusting the Sta-

ple Position

Adjusting the Staple Position

When the staple position in front/rear di-

rection is displaced in the front/rear 1-sta-

pling mode or 2-stapling mode.

“Adjusting the Staple Po-

sition ” on page 158

7

Adjusting the Stapler Unit Installation

Position

• When the stapler unit is replaced.

• When the staple position in feed di-

rection is displaced in the front/rear 1-

stapling mode or 2-stapling mode.

“Adjusting the Stapler

Unit Installation Position ”

on page 159

8

Adjusting the Staple-Free Binding Po-

sition

When the staple-free binding position in

the staple-free binding mode.

“Adjusting the Staple-

Free Binding Position ” on

page 161

■ Adjusting the Saddle Stitcher Area

In the case adjusting the Saddle Stitcher Area, adjust folding position at first, and adjust the stitcher.

In the case adjusting folding position, adjust transport direction and skew at first, and adjust front

‐

rear direction.

No

Items

Use case

Refer to

1

Adjusting the

Fold Position

Adjusting the Saddle Paper End Stopper

Installation Angle

If the fold position of the paper stack deliv-

ered from the saddle stitcher unit is

skewed.

“Adjusting the Saddle Paper

End Stopper Installation An-

gle” on page 162

2

Adjusting the Fold Placement

When misalignment occurs in feed direc-

tion.

“Adjusting the Fold Place-

ment ” on page 164

3

Adjusting the Saddle Alignment Plate

Position

When misalignment occurs in front/rear di-

rection.

“Adjusting the Saddle Align-

ment Plate Position ” on

page 165

4

Adjusting the

Saddle Stitch

Adjusting the Stitcher Unit Installation

Position

• When the stitch positions of the front

and rear sides become misaligned

• If you remove or replace the stitcher

unit

“Adjusting the Stitcher Unit

Installation Position ” on

page 167

5. Adjustment

148

Summary of Contents for Staple Finisher-AA1

Page 1: ...Revision 4 0 Staple Finisher AA1 Booklet Finisher AA1 Service Manual ...

Page 12: ...Product Overview 1 Features 5 Specifications 6 Names of Parts 14 Optional Configuration 20 ...

Page 83: ...Periodical Service 3 Periodic Servicing Tasks 76 ...

Page 87: ...3 Remove the 2 Connectors 1 2x 1 4 Parts Replacement and Cleaning 79 ...

Page 89: ...Main Units Parts 4 5 6 7 8 1 2 3 4 Parts Replacement and Cleaning 81 ...

Page 128: ...4x 1 2 2 3 3 2x 4 Parts Replacement and Cleaning 120 ...

Page 150: ...Adjustment 5 Overview 143 Basic Adjustment 148 Adjustments When Replacing Parts 173 Other 184 ...

Page 193: ...Troubleshooting 6 Making Initial Checks 186 Processing Tray Area 187 Saddle Stitcher Area 188 ...

Page 204: ...4 5 6 7 8 9 7 Installation 196 ...

Page 205: ...10 7 Installation 197 ...

Page 223: ...2 3 2x 7 Installation 215 ...

Page 224: ...APPENDICES Service Tools 217 General Circuit Diagram 218 ...