2

2

2-8

2-8

Technology > Various Modes of Control > Outline of operations > Sequence of surface insert operation

Technology > Various Modes of Control > Outline of operations > Sequence of surface insert operation

M6

S16

S21

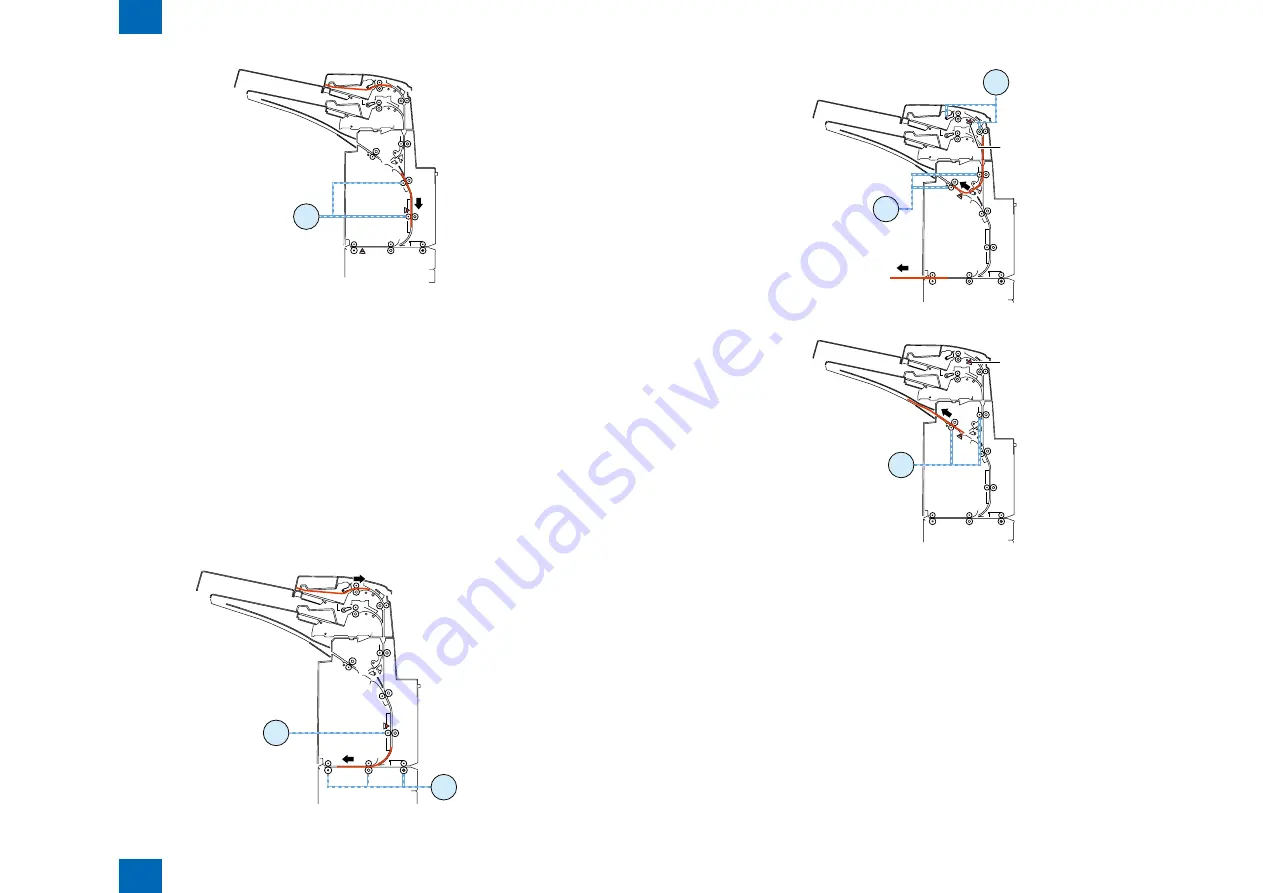

(5) First paper feeding to horizontal feed lock

- When an Entry signal for the first paper is received, the entrance motor 1 turns in the reverse

direction at the same speed as that of the motor in the host machine and the reverse motor turns

in the reverse direction at the same speed as that of the motor in the host machine, thus feeding

the paper to the horizontal feed lock.

- When the paper has been fed 51.2 mm since the reverse timing sensor was turned off, the reverse

motor stops.

(6) Second paper feeding for reversal

- After the reverse feed motor stops as mentioned above, the tray feed motor turns in the normal

direction at a speed of 400 mm/s and the reverse motor turns in the normal direction to start

feeding the paper to the standy position.

- In case of paper feed from the upper tray, the tray paper feed motor stops when the paper has been

fed 64.6 mm since the registration sensor turned off. In case of paper feed from the lower tray, the

tray paper feed motor stops when the paper has been fed 10.3 mm since the registration sensor

turned off.

- The reverse motor stops when the paper has been fed 19.2 mm since the reverse sensor turned

off.

M6

S16

M5

F-2-14

F-2-14

F-2-15

F-2-15

S3

S17

M6

M1

S3

S17

M6

F-2-16

F-2-16

F-2-17

F-2-17

Summary of Contents for K1

Page 4: ...0 0 ...

Page 10: ...1 1 Product Outline Product Outline Features Specifications Names of Parts ...

Page 34: ...3 3 Periodic Servicing P e r i o d i c Servicing Periodic services items ...

Page 69: ...5 5 Adjustment Adjustment Adjustment at Time of Parts Replacement ...

Page 90: ...7 7 Appendix Appendix Service Tools General Circuit Diagram ...