Introduction to the 'Media' section

Introduction

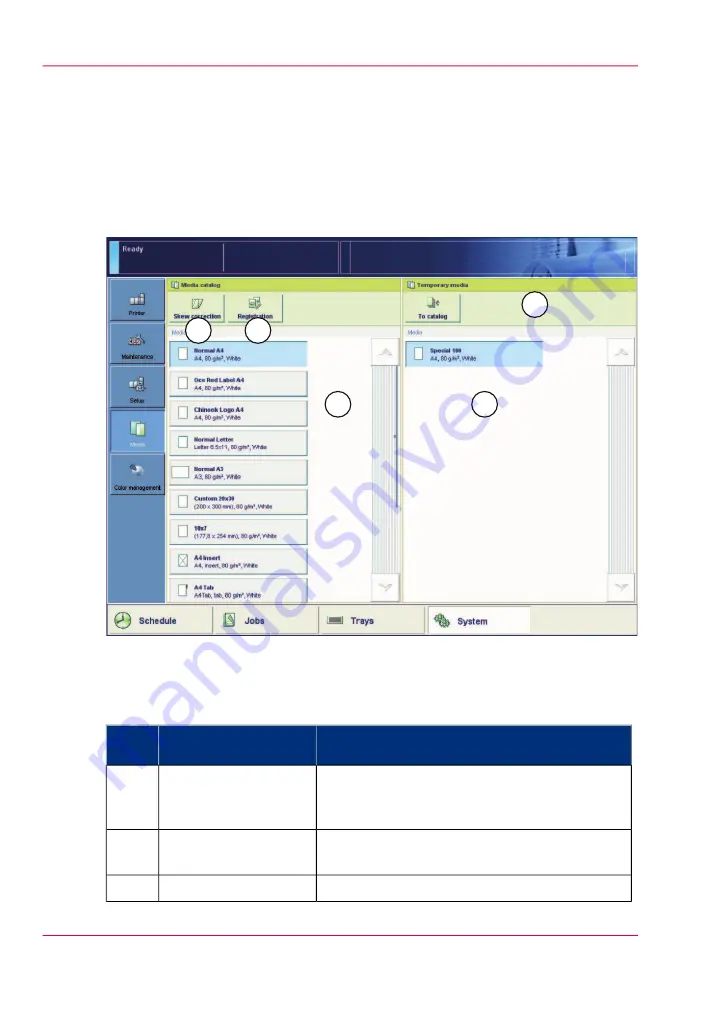

This section gives an overview of the 'Media' section in the 'System' view.

Overview of the 'Media' section

3

4

1

2

5

[146] Overview of the 'Media' section

The items of the 'Media' section

Description of the 'Media' section

#

Function

Item

Num-

ber

Display the current content of the 'Media catalog'.

List of all the media

that are available in the

'Media catalog'

1

Display the temporary media that are currently

available on the system.

List of temporary media

2

Add temporary media to the media catalog.

'To catalog' button

3

Chapter 6 - Print jobs

140

Introduction to the 'Media' section

Summary of Contents for IMAGEPRESS C7010VPS

Page 1: ...Operating Information...

Page 8: ...8 Contents...

Page 9: ...Chapter 1 Preface...

Page 15: ...Chapter 2 Main parts...

Page 55: ...Chapter 3 Operating concept...

Page 78: ...Chapter 3 Operating concept 78 Manage production printing...

Page 79: ...Chapter 4 Operator panel views...

Page 88: ...Chapter 4 Operator panel views 88 The System view...

Page 89: ...Chapter 5 Power information...

Page 97: ...Chapter 6 Print jobs...

Page 120: ...Delete print jobs on page 125 Chapter 6 Print jobs 120 Reprint a job...

Page 167: ...Chapter 7 Copy jobs...

Page 205: ...Chapter 8 Scan jobs...

Page 220: ...Chapter 8 Scan jobs 220 Combine subsets into one file...

Page 221: ...Chapter 9 Paper toner and staples...

Page 305: ...Chapter 10 Adapt printer settings to your needs...

Page 331: ...Chapter 11 Maintenance and calibra tion...

Page 351: ...Chapter 12 Specifications...

Page 370: ...Chapter 12 Specifications 370 Specifications...

Page 371: ...Chapter 13 Third Party Software...