6

6

6-8

6-8

Trouble Shooting > Trouble Shooting Items > Adjustment of Fixing System > Nip-width Specifications

Trouble Shooting > Trouble Shooting Items > Adjustment of Fixing System > Nip-width Specifications

Misformed Image

Image is misformed

Cause

Solution

1) Poor contact exists to the connectors on the

laser scanner unit

Reconnect the connectors: J801 and J802

2) Poor contact exists to the connectors on the

formatter

Reconnect the connectors: J3 and J7

3) The laser scanner unit is defective

Replace the laser scanner unit.

4) The high-voltage power supply is defective

Replace the engine controller unit.

Repetitive Image Defects Ruler

Component

Distance

between

defects (mm)

Image defects

Dirt

Dropouts

Dirt on back

Loose toner

Registration roller

About 43

Primary charging roller

About 38

Photosensitive drum

About 75

Developing roller

About 42

Transfer roller

About 39

Fixing film unit

About 57

Pressure roller

About 63

■

■

F-6-15

F-6-15

T-6-13

T-6-13

T-6-14

T-6-14

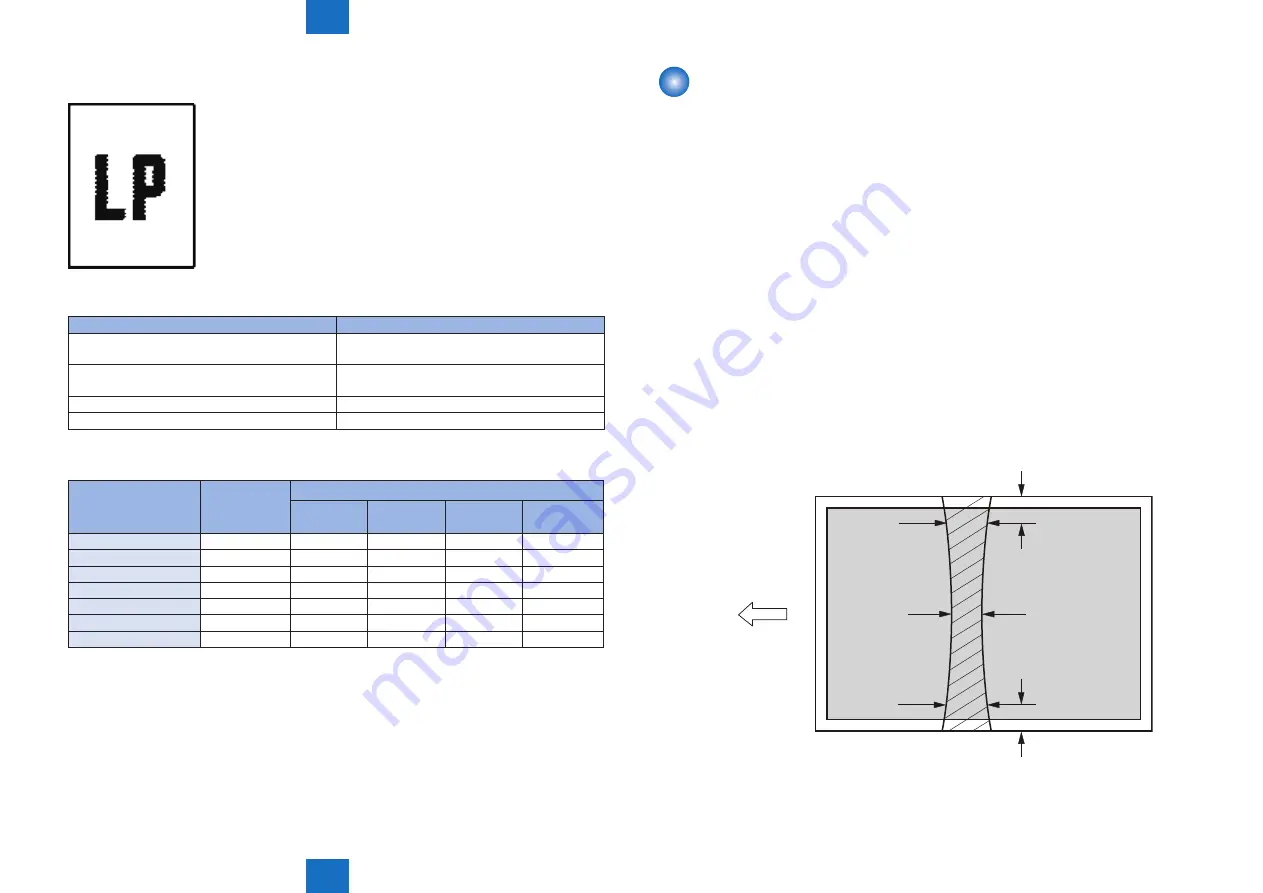

Adjustment of Fixing System

Nip-width Specifications

The nip-width of the fixing unit is not adjustable in this printer, however the improper nip-width

may cause the poor fixing.

Follow the procedures below to check the nip width.

1) Prepare an all-black print of letter size that is printed with the cartridge for this printer

before visiting the user.

2) Load the printed sheet facing UP in the printer cassette.

3) Open the face-up cover.

4) Print a test page.

5) Turn off the power switch when the leading edge of media comes out of the face-up

delivery slot.Wait for 20 seconds and turn on the power switch. Then open the jam removal

cover and pull the paper out.

6) Measure the width of the glossy band across the paper and check if it meets the

requirements below:

Center (a): 6 to 9 mm

Left (b): 6 to 9 mm

Right (c): 6 to 9 mm

c

b

a

15mm

15mm

Media feed direction

Center of

letter sized paper

■

•

•

•

F-6-16

F-6-16