1-1

CHAPTER 1 MAINTENANCE AND INSPECTION

CHAPTER 1 MAINTENANCE AND INSPECTION

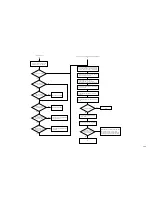

A. Scheduled Servicing List

1. Copier

Caution:

Do not use solvents or oils other than those listed.

Externals and

controls

Original

exposure

Pickup/

feeding

Transfer drum

Laser exposure

Charging

Copyboard glass

Copyboard cover

Ozone filter

Air filter

Toner filter

Original reflecting cover

No. 1 through No. 3 mirrors,

Lens Scanner rail

Attraction, registration

spring clutch

Attraction roller

Attraction roller cleaner pan

Registration roller

Pre-registration roller 2

Pre-registration roller 1

Registration path middle guide

Pickup vertical path roller

Transfer drum cleaner

Jam sensor (PS6) metal plate

(resin tape used for No.2

static eliminator mount)

Jam sensor (PS5) metal plate

(polishing roller motor

mounting plate)

Dust-proofing glass

Shielding plate, block

Use alcohol.

Or, 1 yr.

Or, 1 yr.

Or, 1 yr.

Use blower brush.

After cleaning, apply

silicone oil.

Use lubricant.

Remove unit, and clean.

Remove unit, and clean.

Remove unit, and clean. every 250,000

Remove unit, and clean.

Clean every 250,000

Clean the guide surface. every 250,000

Clean every 250,000

Apply lubricant to the

busihg of the brush.

Clean with lint-free paper;

then, clean with alcohol.

Be sure the part is

completely dry before

mounting.

Do not use water.

For post-cleaning charging

assembly, clean every

20,000 copies.

Unit

Part

Intervals

every

25,000

every

40,000

every

50,000

Remarks

Clean Replace Lubricate Adjust Inspect

As of December 2000

every

20,000

1