2-7

CHAPTER 2 STANDARDS AND ADJUSTMENTS

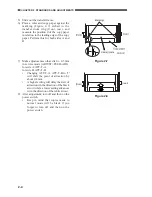

e. Adjusting the Image Read Start

Position (ADJ-XY)

1) Place the Test Sheet on the copyboard

glass.

2) Select ADJUST>ADJ-XY in service

mode.

3) on the ADJ-XY screen, press the Copy

Start key.

•

The appropriate copying mode will

automatically be selected, and a copy

is made with a shift of about 50 mm as

shown in the figure.

Figure 2-13

4) If part of the image is missing, decrease

the setting of ADJ-X, ADJ-Y in service

mode.

5) If part of the image is outside the image

area, increase the setting of ADJ-X, ADJ-

Y.

6) Press the Copy Start key once again, and

make a check.

7) Press the Reset key.

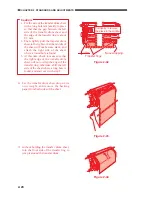

f.

Adjusting the Image Trailing Edge

Margin (TR-END-A, B; end of transfer

high voltage)

If you have replaced the transfer drum

unit in the field, correct the variation in the end

of the transfer voltage.

1) Select ADJUST>FEED-ADJ>TR-END-

A or B in service mode, and enter '25' (10

mm).

2) Select ADJUST>FEED-ADJ>TR2-ON;

then, press the OK key.

3) Measure the distance X (mm) between the

point at which blurring starts along the

trailing edge of the image on the

generated test print and the trailing edge

of the image.

4) Enter the result of (10 - x)/0.4 as the

adjustment value of TR-END-A or -B.

(Round the result up to a whole number.)

5) Select ADJUST>FEED-ADJ>TR2-ON in

service mode once again; then, press the

OK key.

6) Check to make sure that the image along

the trailing edge of the generated test print

is not blurred.

7) Record the value of ADJUST>FEED-

ADJ>TR-END-A or -B on the service

label.

ADJ-X

ADJ-Y

50

50

Figure 2-13a