The operation of circuit breaker has two modes: manual operation and electric operation. Operating mechanism of circuit breaker makes use of cam

to compress a group of energy-storage spring to reach the aim of energy storing, makes use of the energy of energy-storage spring during releasing

to close the circuit breaker, the closing speed has no relation to electric or manual operating speed. Circuit breaker will carry out energy pre-storage

under closing state for the next closing. The operating mechanism has function of free tripping. The circuit breaker has three types of working

position, whose operating process as follows:

Energy storage

External force of electric operation or manual operation drives the cam to rotate, the energy-storage lever on the cam rotates along with it. During the

rotation of cam, energy-storage spring is compressed continuously until the cam rotates to a certain angle (finish position of energy storage); the

reaction force of energy-storage lever will push the cam to go on rotating (turn to energy releasing position), in the meantime, the fixed shaft on the

cam is just pressed against the lever 1, and the other end of lever 1 is locked by the energy-releasing tripping half-shaft, so the “go on rotating” of

cam also is locked (in energy-storage position). On the other hand, when the external force of electric operation or manual operation helps the

energy storing of energy-storage spring, cam drives the connecting rod 1 to rotate, the lever 2 on connecting rod 1 rotates towards the re-trip

position, when reaching the re-trip position, the tripping half-shaft is rotated to the re-trip position under the action of spring force on the re-trip half-

shaft, so as to finish the re-trip process. Now the energy storage is finished, it is ready for closing of circuit breaker.

Closing

Press the closing button or closing electromagnet, let the half-shaft of energy-releasing release rotate counterclockwise, then the lever 1 pressing

against the energy-releasing tripping half-shaft trips, cam rotates clockwise under the action of energy-storage spring force until reaching the cam

gap, energy-storage lever rotates counterclockwise under the action of energy-storage spring force, axle pin on the energy-storage lever just hits

the connecting rod 2 fiercely, which enables the connecting rod 2 to rotate, and drives the connecting rod 1 and connecting rod 3 to run, as the

running direction (by means of force transmission of lever 2) of connecting rod 1 is locked by the tripping half-shaft, then the connecting rod 3

pushes the main shaft 8 to rotate clockwise, to close the circuit breaker.

Breaking

Let the shunt tripping half-shaft (10) rotate clockwise by pressing the opening button or through the tripping operation from under-voltage release,

shunt release and intelligent release, lever 2 trips, force pressing against the connecting rod 1 is disappeared, and now the connecting rod 1 is in free

state, the four-rod link mechanism composed of connecting rod 1, 2 and 3 now becomes five-rod linkage mechanism, under the action of contact

reaction force and backspring force, the circuit breaker opens quickly.

Electric energy-storage mechanism

The electric energy-storage mechanism is composed of motor, position limited inching switch and a group of gear reduction system that has

planetary gear, used for energy storing and energy pre-storing of operating mechanism.

10

C&S Electric Limited

11

C&S Electric Limited

Constructions Characteristics

Operating Mechanism

Contact System

Constructions Characteristics

Contact system of each phase is installed in a small chamber that is made up of insulating

materials, with arc-extinguish chamber above it. Contact system is connected with the

main shaft outside the insulating base through connecting rod, so as to finish the closing

and opening operations.

In order to reduce the electric repulsion and improve the reliability, contact system of

each phase adopts parallel connection of 10~14 moving contacts that are installed on a

contact support.

One end of contacting piece of the contact is connected with the busbar through flexible

connection.

When the circuit breaker closes, the main shaft drives the connecting rod to make the

contact support revolve around the point “A” counterclockwise, after the moving contact

touches the static contact, the contact support will continue to rotate around the point

“A” counterclockwise, while the moving contact will rotate around the point “B”

clockwise to compress the spring, so as to produce a certain contact force that

guarantees reliable closing of circuit breaker.

Static Contact

Main Saft

Connecting rod

Contact support

Busbar

Flexible connection

Moving contact

A

B

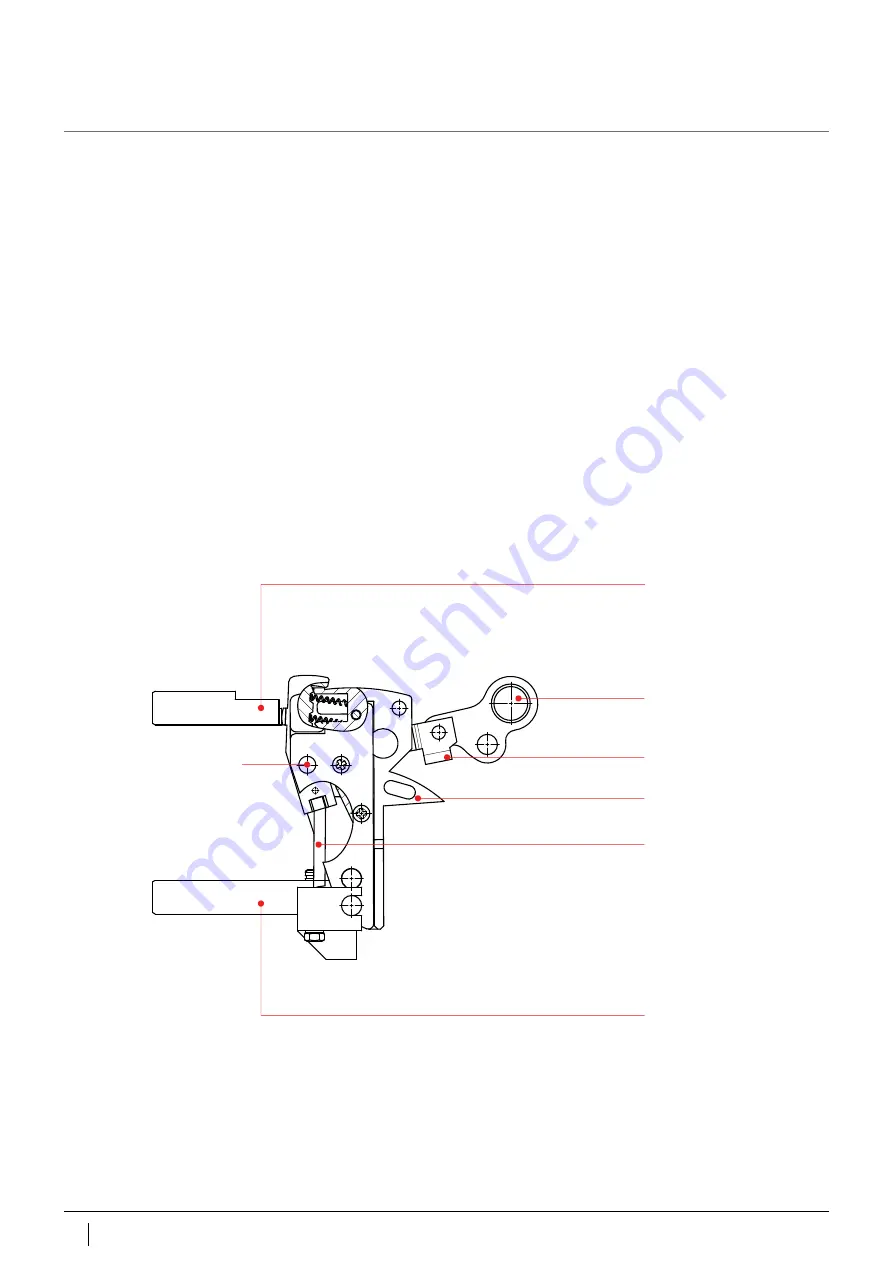

Energy releasing tripping half-shaft

Lever

Connecting rod 2

Energy storage lever

Energy storage spring

Cam

Connecting rod 1

Main shaft

Connecting rod 3

Breaking tripping -shaft

Lever 2

2

3

1

4

5

6

7

8

9

10

11

11

1

2

3

4

5

6

7

8

9

10

W Nmaster 2

i

W Nmaster 2

i

Summary of Contents for WiNmaster 2

Page 1: ...Air Circuit Breaker Ro S H Compliant W Nmaster 2 i 630A 3200A www cselectric co in ...

Page 3: ......

Page 5: ...6 C S Electric Limited Complete Modular construction ...

Page 7: ...Fixed Type Drawout Type 8 C S Electric Limited Available in both Fixed Drawout version ...

Page 13: ...RoHS Compliant 14 C S Electric Limited ...

Page 15: ......

Page 16: ......

Page 25: ......

Page 35: ......

Page 36: ...Micropro 2 3 1 Micropro 2 4 1 37 C S Electric Limited Characteristics Curve W Nmaster2 i ...

Page 50: ...51 C S Electric Limited ...

Page 60: ......