4

1.4

– Sequence of Operation

1.

Supply power connection as per Section 1.3.2.

2.

The power switch is placed in the “ON” position. 120 VAC

power is supplied to the control transformer. 24 VAC is

supplied to the ignition module and low voltage controls for

all models.

3.

If a Low Water Cut-off (LWCO) is supplied, it must be closed

to allow operation. The LWCO is to be wired into the

appropriate contacts on the unit control panel.

4.

The control activates the unit when the temperature

measured by the top tank sensor drops below the setpoint

(“SETPOINT”) by the programmed tank differential (“DIFF

ON

”).

5.

The control energizes the blower, increasing the voltage to

the electrically commutated DC motor on the combustion fan.

6.

If the airflow switches are closed the fan will run at pre-purge

speed until the pre-purge timer is satisfied.

7.

After pre-purge, the control will target the ignition fan speed.

8.

The control energizes the hot surface igniter for about 10

seconds. At the end of this period, the main gas valve is

energized for 4 seconds, during which time the flame must be

established.

9.

The hot surface igniter is de-energized at the end of the

ignition period.

10.

At the end of the flame establishing period, a signal of 0.8 Vdc

must be recognized by the controller at the flame sensor

(“

CURRENT

”) to keep the main gas valve in an open position.

The fan is kept at ignition speed until the stabilization timer is

satisfied, and the main flame is established.

11. The control will enter operation and release to modulation.

12. The control will modulate fan speed through Pulse Width

Modulation (PWM), adjusting water heater input to meet and

then maintain target temperature.

13. Fan speeds will modulate down when the temperature

measured by the temperature sensor is approaching setpoint.

14. The control will stage the unit off when the temperature

measured by the top tank sensor reaches setpoint.

15. The burner will shut off and the fan speed will ramp up to

post-purge speed until the post-purge timer is satisfied.

16. The unit will then go into standby until the next demand.

1.5

– Codes

The equipment shall be installed in accordance with those

installation regulations in force in the local area where the

installation is to be made.

These shall be carefully followed in

all cases. Authorities having jurisdiction shall be consulted before

installations are made. In the absence of such requirements, the

installation shall conform to the latest edition of the National Fuel

Gas Code, ANSI Z223.1. NFPD 54 and/or CSA B149.1-15 and

CSA B149.2-15 Natural Gas and Propane Installation Code. All

electrical wiring must be done in accordance with the

requirements of the authority having jurisdiction or, in the

absence of such requirements, with National Electrical Code,

ANSI/NFPA70 and/or the Canadian Electrical Code part 1 CSA

C22.1. Where required by the authority having jurisdiction, the

installation must conform to American Society of Mechanical

Engineers Safety Code for Controls and Safety Devices for

Automatically Fired Boilers, ASME CSD-1. All water heaters

conform to the latest edition of the ASME Boiler and Pressure

Vessel Code, Section II. Where required by the authority having

jurisdiction, the installation must comply with the CSA

International, CSA B149.1-15 and CSA B149.2-15 and/or local

codes. This appliance meets the safe lighting performance

criteria with the gas manifold and control assembly provided, as

specified in the ANSI standards for gas-fired units, ANSI

Z21.10.3.

1.6

– Warranty

Factory warranty (shipped with unit) does not apply to units

improperly installed or improperly operated.

Factory warranty (shipped with unit) does not apply to units

with no or improperly installed or operated

pump assembly

.

Factory warranty shall apply only when the appliance is

installed in accordance with local plumbing and building

codes, ordinances and regulations, the printed instructions

provided with it and industry best practices.

Excessive

water hardness

causing a scale buildup in the

stainless steel coils or tubes is not a fault of the appliance and

is not covered by warranty.

Using or storing

corrosive chemicals

in the vicinity of this

appliance can rapidly attack the stainless steel tubes and

coils and voids warranty.

Damage caused by

freezing or dry firing

voids warranty.

This appliance is not to be used for

temporary service

of

buildings under construction.

The manufacturer shall

NOT

be held liable for any personal

injury or property damage due to ice formation or the

dislodging of ice from the vent system or the vent termination.

1.7

– Scald Prevention

Water should be stored above 122

°

F (50

°

C) to avoid the bacterial

growth that happens at cooler temperatures. B

acteria won’t grow

above this level but are not destroyed, so systems often require

water be heated to 158

°

F (70

°

C) or above to kill any bacteria that

are present (140-160

°

F (60-71

°

C) is common in commercial

kitchens). This temperature causes the water to become more

aggressively corrosive, shortening the tank’s service life, so the

commonly recommended storage temperature is 140

°

F (60

°

C).

These temperatures have the potential to scald with enough

exposure time, so thermostatic mixing valves that temper water

to safe levels should be provided. Such valves are required in

some jurisdictions. Storing and mixing water to cooler levels also

increases the effective storage volume, maximizing the delivery

potential of a given tank capacity.

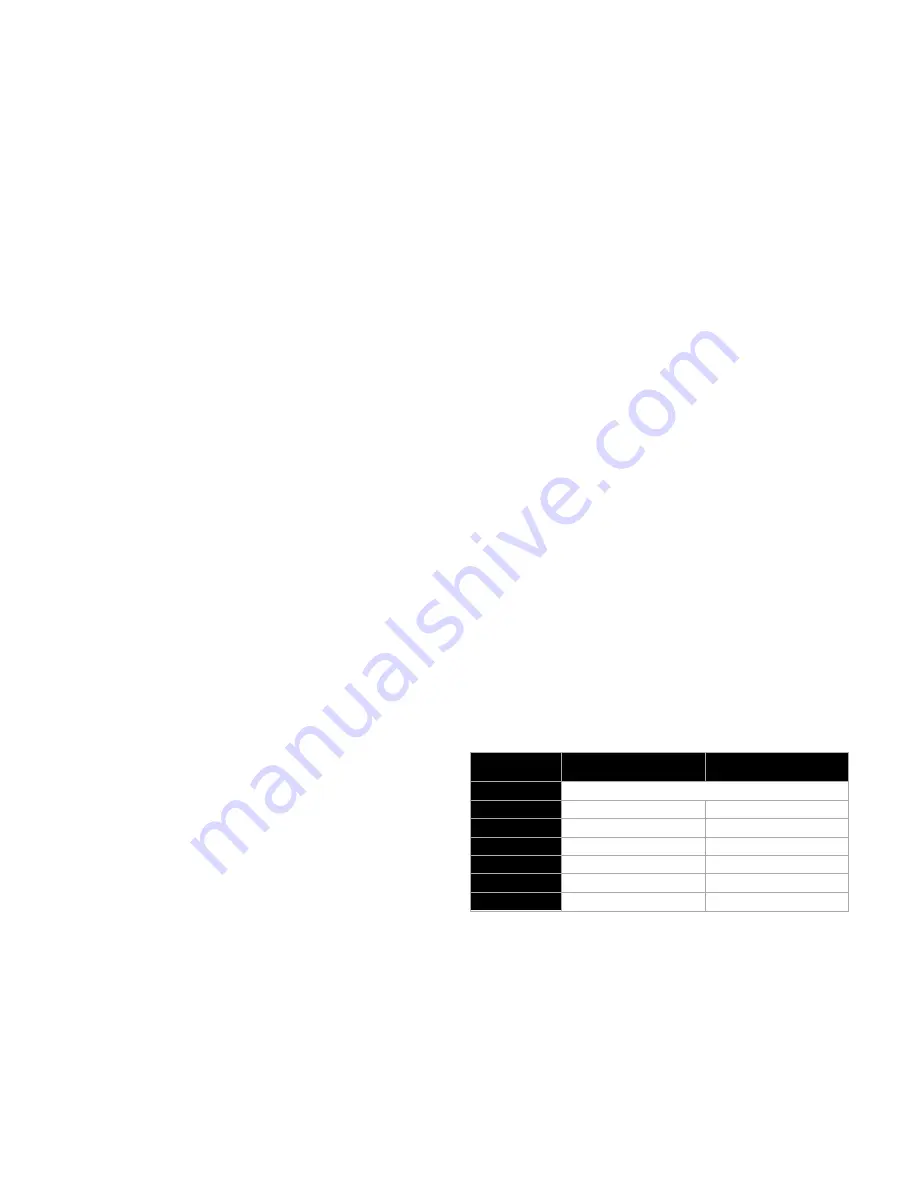

Temperature,

°

F (

°

C)

Time for 1

st

Degree

Burn (Less Severe)

Time for 2

nd

or 3

rd

Degree Burn

110 (43)

High-end of Normal Shower Temperatures

116 (47)

35 Minutes

45 Minutes

122 (50)

1 Minute

5 Minutes

131 (55)

5 Seconds

25 Seconds

140 (60)

2 Seconds

5 Seconds

149 (65)

1 Second

2 Seconds

154 (68)

Instant

1 Second

Part 2 – Installation

2.1

– Checking the Equipment

Check for signs of shipping damage upon receiving equipment.

Pay particular attention to the powder coat stainless finish outer

shell, which may show signs of being hit or otherwise being

mishandled. Verify total number of pieces shown on packing slip

with those actually received. In case there is damage or a

shortage, immediately notify freight carrier. Pump assembly

ships lose with the unit which needs to be installed in the field.