31

Part 8 – Commissioning/Start-up

8.1

– Checking the Installation

Inspect the water, gas and electrical connections. Confirm they

are all in compliance with the instructions in this manual. Verify

gas pressure is within the ranges listed in Table 4 before

proceeding. Confirm that all gas connections to the heater are

tight, and that there are no leaks or missing test plugs.

Repair

any leaks and replace plugs before proceeding.

All units are test fired and factory set. A test sticker with

actual reading is affixed to the unit.

Check the wiring to see that it agrees with the wiring diagram

supplied. Confirm that all terminal strips and field connections are

identified. Confirm that the VTech controller is set in the proper

mode. Auto reset limits are fixed in all modes.

The coldest water temperature possible must be used when

setting up low fire combustion. Cold temperatures cause flue

products to condense, resulting in large amounts of condensate

build up on the stainless steel heat transfer tubes, which in turn

creates the highest back pressure through the unit. At minimum

input this creates the most critical combustion setup point. It is

recommended to perform setup under these conditions quickly,

to ensure low temperatures are maintained throughout the

commissioning, for single or multiple appliance installations.

8.2

– Checking Gas Supply Pressure

Turn the main power switch to “OFF” position.

Shut off gas supply at the manual gas cock in the gas piping

to the appliance. If fuel supply is LP gas, shut off gas supply

at the tank.

Remove the 1/8" hex plug from the gas pressure test port

located on the inlet gas supply connection at the rear of the

appliance. Install a fitting in the inlet pressure tapping suitable

to connect to a manometer (or magnahelic gauge). Range of

scale should be 0 to 14 inch WC or greater.

Turn on gas supply at the field installed manual gas cock; turn

on LP gas at tank if required.

Ensure inlet pressure is within specified range. Minimum and

maximum gas supply pressures are specified in Table 4.

IMPORTANT

If gas pressure is out of range, contact the gas utility, gas

supplier, qualified installer or service agency to determine

necessary steps to provide proper gas pressure to the control.

Upon completion of any change to the gas system, leak test

all gas connections with a soap solution Immediately repair

any leak found in the gas train or related components. DO

NOT operate an appliance with a leak in the gas train, valves

or related gas piping.

Do not attempt to fire the unit with insufficient gas supply

pressure. Never use an open flame (match, lighter, etc.)

to check gas connections.

Turn the power switch to “ON” position. If filled with cold water

the tank should automatically observe a demand to heat the

water. Verify target temperature is higher than current water

temperature.

Once safety checks are complete, the control will run through

the ignition cycle. It is normal during initial startup, when air

is being purged from the piping, to require several attempts

before successful ignition. This may require clearing a lockout

for failed ignition.

Continued ignition failures may indicate

a problem with the gas supply.

When ignition is successful and the unit is in operation, check

for flue gas leaks along the inner cabinet joints and around

the flue outlet. If any leaks are found, deactivate the unit and

repair immediately.

Unit should modulate to 100% of rated input, observe the gas

supply pressure at this level. Ensure that gas pressure

remains stable within the ranges listed in Table 4. The inlet

gas pressure must not exceed a 30% reduction between

light-off and full fire conditions.

If gas supply pressure is within normal range, proceed adjust

combustion settings, if necessary.

8.3

– Combustion Setup

At the factory adjustments were made to achieve proper input

and acceptable burner performance at full input and at minimum

input. Depending on field conditions, the combustion setup may

require some adjustment. To ensure the coldest possible water

temperatures for set up on multiple water heater systems, the low

fire combustion should be established on all water heaters before

setting any water heater high fire combustion rates.

Table 6: Target Combustion Values

Natural Gas

Propane

CO

2

CO

CO

2

CO

Max. Input

8.5% - 9.0%

<100

PPM

9.5% - 10.0%

<100

PPM

Min. Input

8.0% - 8.5%

<100

PPM

9.0% - 9.5%

<100

PPM

In order to perform adjustments to the gas valve the VTech must

be firing before proceeding, and the gas inlet pressure must

already have been verified.

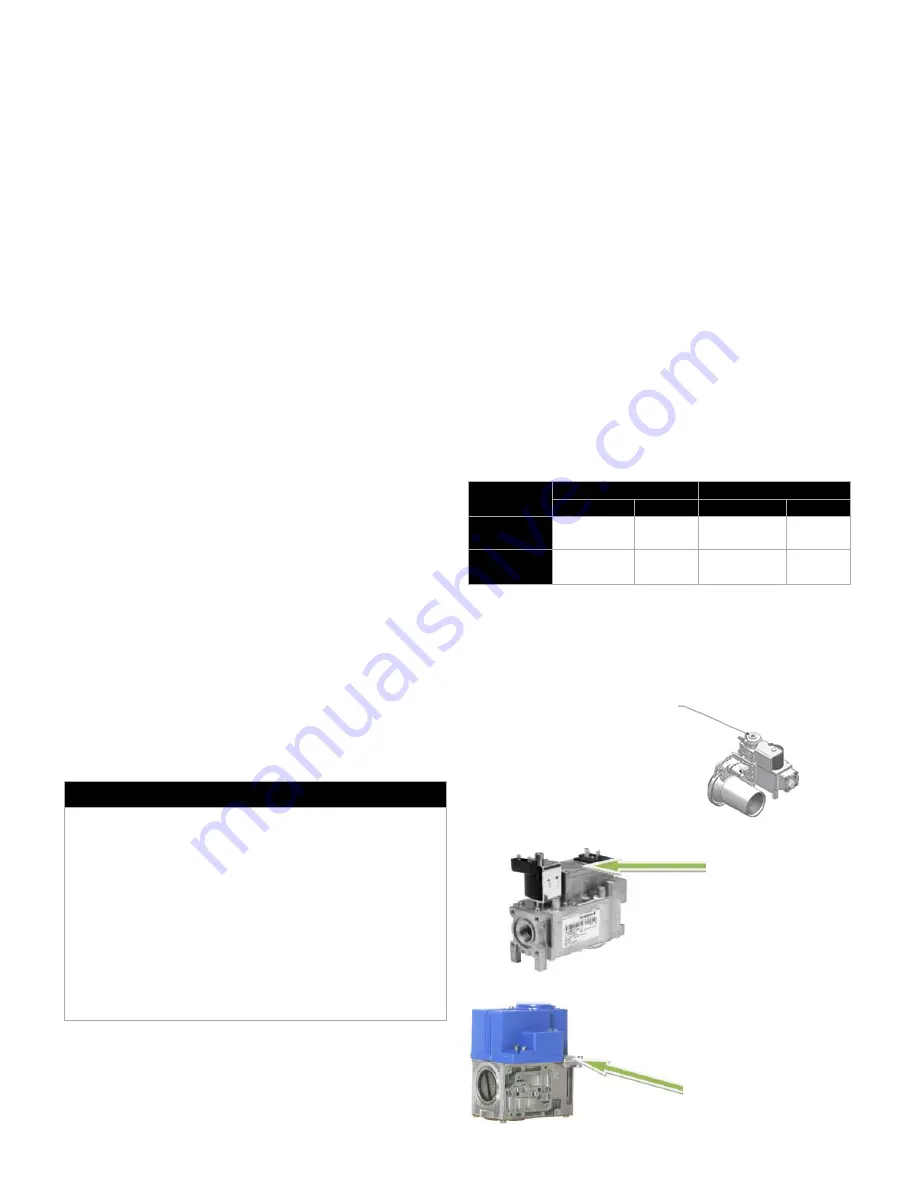

8.3.1

– Adjust Low Fire Setting

VT80 to 250

– Negative Pressure Control Valve

VT299 to VT399

– Negative Pressure Control Valve

VT499

– Negative Pressure Control Valve

Low-fire air gas ratio

adjustment (use Torx 40

for adjustment clockwise

increases CO

2

)

Low-fire air/gas ratio

adjustment, use slotted

screwdriver for adjustment,

clockwise increases CO

2

Low-fire adjustment

screw (use Torx 40 for

adjustment, clockwise

increases CO

2

)