MAINTENANCE

OPERATOR MANUAL

68

EPS14P

69

OM-EPS14P2019001-EN

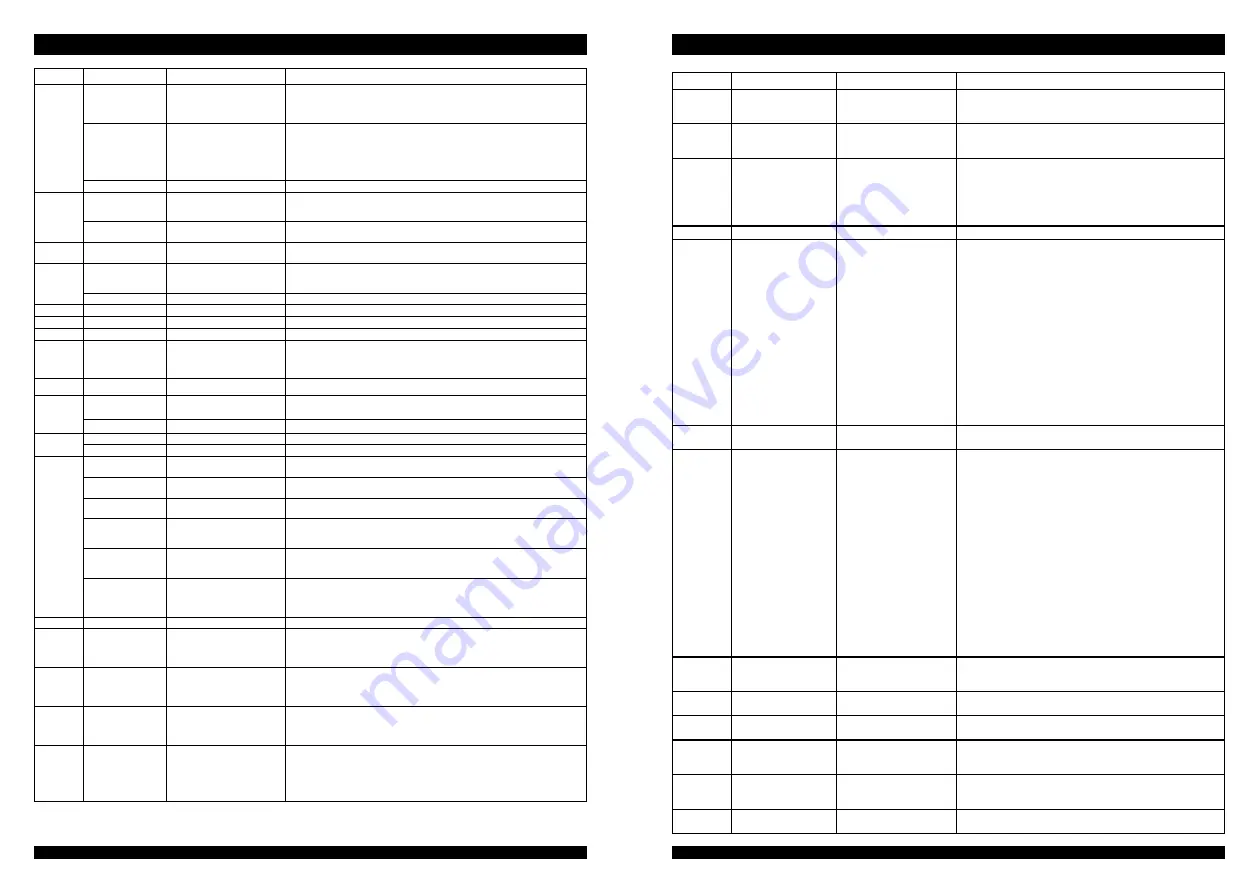

Display

ALARM

Fault name

Recommended inspection

02A89

POWER MOS SHORT

Short circuit of the power MOS

tube

Before the main contactor engages, the software can check the power bridge.

Convert the low end power of the MOS tube. Lower the phase voltage to –BATT (lift

to +BATT). If the phase voltage variation does not agree with the command, this

fault can occur. Replace the controller. Replace the controller.

PUMP VACC NOT OK

Oil pump lift speed regulation

sensor fault

Inspection time: With the forklift idling, the lift speed regulation sensor voltage

is at least 1V higher than the minimum set in the “PROGRAM VACC” menu for

accelerator signal range. Possible causes:

1.Upper and lower voltage limits of the lift speed regulation sensor have not been

taken. Move to the “PROGRAM VACC” menu and take them again;2.Lift speed

regulation sensor error3.Controller fault.

pev not ok

Not used in BYD system

02A90

PUMP VACC RANGE

Oil pump lift speed regulation

sensor signal is outside the

range

1. Upper and lower voltage limits of the lift speed regulation sensor have not been

correctly taken. Move to the “PROGRAM VACC” menu and take them again; 2.

Check whether the wiring of the lift speed regulation sensor is correct;

lift+lower

Trigger the lifting and lowering

at the same time

Check if the tiller switch signal is normal

02A91

lift low active

Lowering switch is triggered

The lowering switch is triggered when the vehicle is turned on, please check the

lowering switch

02A92

CURRENT GAIN

Fault with current gain

Maximum current gain is the factory set value. It indicates that the maximum

current adjustment procedure has not yet been initiated. Solution: ZAPI technician

correctly sets the current gain parameter.

canbus ko tiller

Tiller communication fault

Check CAN communication wire

02A93

wrong battery

Voltage level setting error

Check whether the battery voltage is normal.

02A94

data acquisition

Data update error

Controller parameter settings cannot be changed while the controller is working.

02A95

INPUT ERROR #2

Input error #2

02A96

ANALOG INPUT

Analogue signal input fault

This fault occurs when all analogue signals are converted into the same value by

the A/D converter, with delay exceeding 400ms. This function is used to detect

fault with the A/D converter or conversion of analogue signal. Fault analysis: If this

fault persists, replace the controller.

02A97

input error#1

Check whether A13 input is normal

02A98

reload hm from mdi

Not used in BYD system

input error#2

Check whether A14 input is normal

02A99

SLIP_PROFILE

Slip fault

“SLIP PROFILE” selection error. Check hardware parameter settings.

checkup needed

Checkup needed

Check interval is expired. Contact the service personnel to check.

06A00

STEER HAZARD

Steering angle exceeds limit

1. Reduce the steering angle and restart the key; 2. Change the internal angle

parameter setting of steering controller;

EMERGENCY

Emergency reverse

After completing the emergency reverse, engage the interlock switch again and

the fault disappears.

WAITING DATA

Waiting for data

1.Check if the CAN BUS communication line is connected properly;

2.Check if the bit rate of the communication is consistent;

EPS NOT ALIGNED

Zero not found

1.Check if the zero proximity switch is installed properly;

2.Check if the zero proximity switch is correctly selected;

3.Check if the output data of zero proximity switch is correct;

WAITING FOR TRAC

Waiting for towing controller

1.Check if the CAN BUS communication line is connected properly;

2.Check if the connection line of interlock switch is correct;

3.If the interlock switch is controlled by tiller, set TILLER SEITCH as HANDLE;

KEYOFF

Key switch voltage low

1.Check if the key switch voltage receives a low voltage pulse when turning on the

external load;

2.Check if B+ and B- are firmly connected to the controller;

3.If the fault is reported every time the key is turned on, replace the controller;

06A01

HIGH CURRENT

Current over high

1. Check if the steering controller matches the motor; 2. Replace the controller

06A02

POWER FAILURE #1

Power fault #1

1.Check if the controller fuse is normal;

2.Check if power supply cable is firmly connected to the controller;

3.Check if the controller W phase wire is connected properly;

4.Replace the controller;

06A03

POWER FAILURE #2

Power fault #2

1.Check if the controller fuse is normal;

2.Check if power supply cable is firmly connected to the controller;

3.Check if the controller U phase wire is connected properly;

4.Replace the controller;

06A04

POWER FAILURE #3

Power fault #3

1.Check if the controller fuse is normal;

2.Check if power supply cable is firmly connected to the controller;

3.Check if the controller V phase wire is connected properly;

4.Replace the controller;

06A05

STBY I HIGH

Standby current is high

Checks whether the motor current is zero via controller in the vehicle standby

state. If it is not zero, this fault occurs, stop the vehicle immediately. Possible

cause:

1. One end of the terminal is connected directly to another load rather than to a

drive motor, such as a lift motor. 2. Current sensor or logic card damaged. Replace

the logic card first. If the fault persists, replace the power part.

Display

ALARM

Fault name

Recommended inspection

06A06

D LINE SENSOR KO

Step motor D LINE voltage

failure

1.Check if the stepper motor cable is intact;

2.Resistance between D line and B- too small (Approaching

30Ω);

06A07

Q LINE SENSOR KO

Step motor Q LINE voltage

failure

1.Check if the stepper motor cable is intact;

2.Resistance between Q line and B- too small (Approaching

30Ω);

06A08

EEPROM KO

Memory is damaged

Forklift does not travel. Parameter storage becomes faulty

so that forklift stops operation. Operate the key switch for

several times. If the fault still exists, replace the logic card. If

the fault disappears, parameters previously stored have been

replaced by wrong parameters. It is imperative to set the

parameters again.

06A09

VMN NOT OK

VMN fault

Replace the controller;

06A10

HIGH TEMPERATURE

Temperature overheating

When full power is allowed, the temperature of the controller

exceeds 85 ° C (this temperature is related to the parameter

"MAXIMUM CURRENT"). Corresponding relation is as follows:

Parameter setting

Alarm temperature

MAXIMUM CURRENT=50%

96° C

MAXIMUM CURRENT=60%

94° C

MAXIMUM CURRENT=70%

92° C

MAXIMUM CURRENT=80%

90° C

MAXIMUM CURRENT=90%

88° C

MAXIMUM CURRENT=100%

86° C

At this time, the maximum current of the controller decreases

with increasing temperature. When the temperature is 105

° C, the controller current is reduced to 0. If the chopper is in

a cold state, the fault occurs: 1. The temperature calibration

parameter of logic card is incorrect. Check the parameter. 2.

The internal temperature sensor of the controller has fault. 3.

Check if the temperature sensor itself is damaged.

06A11

DATA ACQUISITION

Data collection

Activation of this fault indicates data acquisition is under

way. Wait data acquisition is completed.

06A12

LOGIC FAILURE #1

Logic card fault 1

Faults caused by under-voltage or over-voltage protection.

In 24V system, the controller detects a voltage above 45V

or below 9V; In 48V system, the controller detects a voltage

above 65V or below 11V

Possible causes:

1.Whether there is short circuit in the circuit system, such as

DC-DC, brake coil, etc., or whether the controller input power

supply is in good contact. (Driving controller)

2.Whether the battery voltage is over low or over high.

(Driving controller)

3.Check if the power cable above the terminals such as B+, B,

main contactor is tight. (Driving controller)

4.Whether the calibration parameter of controller voltage is

consistent with the actual voltage. (Driving controller)

5.Fault with the hardware circuit protected by over-voltage

on the logic card. Replace the controller. (Driving controller)

6.The voltage between W and U does not meet the

requirements, and the controller needs to be replaced;

(Steering controller)

06A13

LOGIC FAILURE #2

Logic card fault 2

The voltage between W and V does not meet the

requirements, and the controller needs to be replaced;

(Steering controller)

06A14

LOGIC FAILURE #3

Logic card fault 3

The output VU-VV of the voltage amplifier exceeds 2.2V-2.8V,

and the controller needs to be replaced; (Steering controller)

06A15

LOGIC FAILURE #4

Logic card fault #4

The output VW-VV of the voltage amplifier exceeds 2.2V-2.8V,

and the controller needs to be replaced; (Steering controller)

06A16

KS CLOSED

Safety contactor of slave

c o n t a c t o r c l o s e d i n

advance

Main contactor monitors the advanced close of safety

contactor of slave contactor, and the controller needs to be

replaced;

06A17

KM CLOSED

Safety contactor of main

c o n t a c t o r c l o s e d i n

advance

Slave contactor monitors the advanced close of safety

contactor of main contactor, and the controller needs to be

replaced;

06A18

KS OPEN

Safety contactor of slave

contactor open

Main contactor monitors the open of safety contactor of

slave contactor, and the controller needs to be replaced;

Summary of Contents for EPS14P

Page 1: ...EPS14P OPERATOR MANUAL OM EPS14P2019001 EN...

Page 2: ...EPS14P OPERATOR MANUAL OM EPS14P2019001 EN...

Page 38: ......