INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 32 of 68

7503-M002-6_B

NAV26HW - NAV26HW.S - NAV26HW.ST

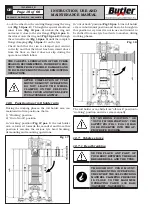

• Check periodically the oil level of the oil-pressure unit

and, in case, carry out the filling up with hydraulic

oil having a viscosity degree suitable for the average

temperatures of the country where the machine is

installed and in particular:

- viscosity 32 (for countries with room temperature

from 0 to 30 degrees);

- viscosity 46 (for countries with room temperature

above 30 degrees).

At least once a year it is advisable to proceed anyway

to the complete replacement of the hydraulic oil of

the hydraulic unit itself.

CARRY OUT THIS CONTROL WIT

THE MACHINE COMPLETELY

CLOSED (WITH HYDRAULIC PIS-

TONS IN).

• Periodically (about every 100 hours), check the oil

level of the reduction gear and eventually reset the

level.

• Check operation of the safety devices every week.

ONLY FOR NAV26HW.S

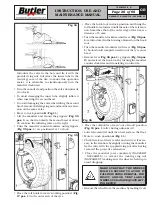

A.

Check the reduction gear oil level (

Fig. 44 pos. 1

);

the level indicator window (

Fig. 44 pos. 2

) must be

covered with lubricant, otherwise, remove the plug

provided and top up using appropriate lubricants

until the level is reset.

Fig. 44

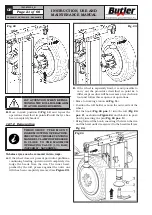

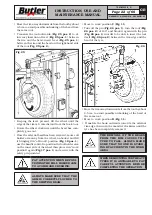

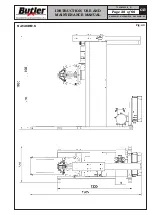

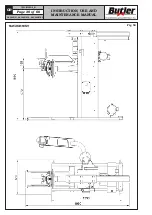

B.

Check the belt tensioning (

Fig. 45-46 pos. 1

):

• Remove protection guard (

Fig. 45-46 pos. 2

) with

a screwdriver.

• Stretch the belt (

Fig. 45-46 pos. 1

) using the screw

(

Fig. 45-46 pos. 3

) after the nuts (

Fig. 45-46 pos.

4

) have been slackened.

• Tighten the fixing nuts (

Fig. 45-46 pos. 4

) after the

adjustment operations, then assemble the protection

guard (

Fig. 45-46 pos. 2

).

ONLY FOR NAV26HW.S

Fig. 45

ONLY FOR NAV26HW - NAV26HW.ST

Fig. 46