INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 20 of 68

A.

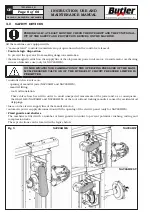

Lock the wheel on the mandrel as described in the

previous paragraph.

B.

Remove all balancing weights from the rim. Extract

the valve and let air out of tyre.

C.

Move to work position

A

(

Fig. 11

).

D.

Position the beading disc on the external side of

the tyre.

ALWAYS VERIFY THAT THE ARM

IS CORRECTLY LOCKED TO THE

SHIFTING BEAM.

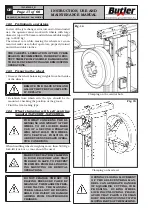

E.

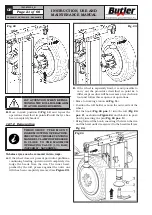

Lift the mandrel (

Fig. 19 pos. 1

) by using the ap-

propriate handle control, until bringing the beading

disc (

Fig. 19 pos. 2

) next to the tyre brim (

Fig. 19

pos. 3

), in contact with the external bead.

Fig. 19

THE BEADING ROLL MUST NOT

EXERT PRESSURE ON THE RIM

BUT ON THE TYRE

BEAD

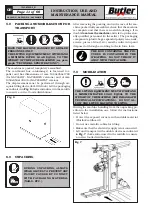

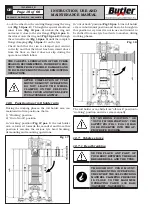

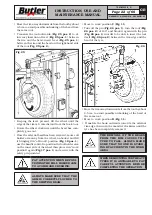

F.

Turn the mandrel counterclockwise and, at the

same time, gradually move the roll (

Fig. 20 pos.

1

) inwards to bead the tyre. Continue to turn the

mandrel while generously lubricating the tyre rim

and bead with a suitable lubricant.

The more the wheel adheres to the rim, the slower

should the beading roll advance.

Fig. 20

USE ONLY TYRE LUBRICANTS.

SUITABLE LUBRICANTS CONTAIN

NO WATER, HYDROCARBONS, OR

SILICON.

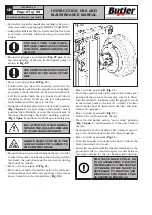

G.

Once external beading has been carried out, unhook

and lift the roll holder arm placing it in “off-work”

position (

Fig. 18 pos. 1

); use the handle control

to position the roll holder arm on the inner side of

the wheel, then place it in “work position” (

Fig. 17

pos. 1

) and secure it with the special safety pin.

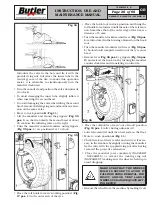

FOR WHEELS WITH MAX. DIAM-

ETER LOWER THAN 1100 MM, IT

IS POSSIBLE TO SHIFT THE BEAD-

ING ROLL INTO THE SAME REAR

BEADING POSITION BY LOWER-

ING THE WHEEL (SEE FIG. 21)

IN ORDER TO BRING IT BACK TO

BEADING POSITION (SEE FIG. 22).

Fig. 21

7503-M002-6_B

NAV26HW - NAV26HW.S - NAV26HW.ST