INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 25 of 68

7503-M002-6_B

NAV26HW - NAV26HW.S - NAV26HW.ST

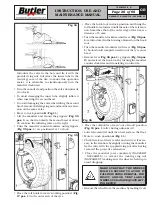

• Mount the grippers in the lowest point (6 o’clock)

outside the second bead.

• Move to work position

B

(

Fig. 11

).

• Turn the mandrel counterclockwise placing the grip-

pers at 1 o’clock.

• Move the tool forward until the the axis of the ref-

erence notch matches the external edge of the rim

coincide at about 5 mm from the rim itself (

Fig. 24

).

Begin clockwise rotation making sure that, after a

90° turn, the second bead begins to slide in the rim

groove. Turn until the grippers reach in the closest

point to the tool (11 o’clock). The second bead should

now be inserted in the rim.

• Move the tool away from the wheel, turn it over into

“out of work” position and remove the grippers.

• Lower the mandrel until the wheel rests on the floor.

• Move to work position

A

(

Fig. 11

).

• Close the mandrel jaws completely (NAV26HW

- NAV26HW.S) or remove the locking ring nut

(NAV26HW.ST) making sure the wheel is held up to

avoid dropping.

MAKE SURE THAT THE WHEEL’S

HOLD IS SECURE TO AVOID IT

FALLING DURING REMOVAL. FOR

HEAVY AND/OR VERY LARGE

WHEELS USE AN ADEQUATE LIFT-

ING DEVICE.

• Remove the wheel from the machine by making it roll.

12.8 Tyres with inner tube

12.8.1 Bead breaking

REMOVE THE LOCK NUT OF THE

INNER TUBE VALVE TO ALLOW

ITS EXTRACTION DURING TYRE

REMOVAL PHASES; REMOVE

THE NUT WHEN DEFLATING THE

TYRE.

The beading procedure is the same one described for

tubeless tyres.

WHEN BEADING WHEELS WITH

INNER TUBES, INTERRUPT THE

FORWARD MOVEMENT OF THE

BEADING ROLL AS SOON AS THE

BEADS HAVE BEEN DISLODGED

TO AVOID DAMAGE TO THE IN-

NER TUBE OR TO THE VALVE.

12.8.2 Demounting

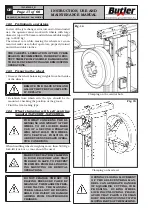

THROUGHOUT TYRE MOUNT-

ING/DEMOUNTING OPERATIONS,

CHECK THAT THE SELF-CENTRING

MANDREL CLAMPING PRESSURE

IS CLOSE TO THE MAXIMUM

OPERATING VALUE (130 BAR)

(NAV26HW - NAV26HW.S).

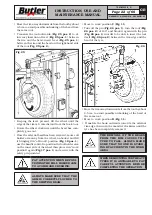

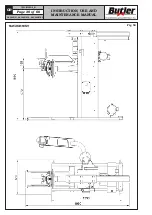

• Bring the roll holder arm in the “out of work” position

(

Fig. 18 pos. 1

); by operating on the handle control

position the roll holder arm on the external side of

the wheel then bring it back into “working” position

(

Fig. 17 pos. 1

) and lock it with the special safety

pin (

Fig. 1, 2

and

3 pos. 12

).

PAY ATTENTION WHEN REPOSI-

TIONING THE ROLL HOLDER ARM

TO AVOID HAND CRUSHING.

ALWAYS MAKE SURE THAT THE

ARM IS CORRECTLY LOCKED TO

THE SHIFTING BEAM.

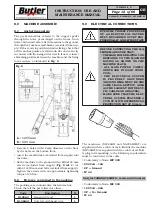

• Mount the hook tool turned towards the tyre in order

to insert the same hook between the rim edge and the

tyre bead; the operation must be carried out during

the mandrel rotation.

• Move the rim away downwards from the tool by about

4-5 cm to avoid possible unhooking of the bead of

the same tool.

• Translate the hook tool outwards until the reference

notch matches the external edge of the rim.

• Move to work position

A

(

Fig. 11

).

• Insert lever (

Fig. 31 pos. 1

) between the rim and the

bead on the right-hand side of the tool.