INSTRUCTION, USE AND

MAINTENANCE MANUAL

GB

Page 27 of 68

• Secure the rim to the mandrel according to the proce-

dure described in paragraph “WHEEL CLAMPING”.

• Adequately lubricate the tyre beads and the rim bead

seat with a suitable lubricant using the provided

brush.

USE ONLY TYRE LUBRICANTS.

SUITABLE LUBRICANTS CONTAIN

NO WATER, HYDROCARBONS, OR

SILICON.

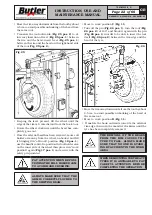

• Mount the grippers (on demand) (

Fig. 27 pos. 1

) on

the external edge of the rim in the highest point as

shown in

Fig. 27

.

THE GRIPPERS MUST BE TIGHTLY

SECURED TO THE EDGE OF THE

RIM.

• Move to work position

B

(

Fig. 11

).

• Position the tyre near the machine and lower the

mandrel (make sure that the grippers are in the high-

est point) to hook the first tyre bead (internal bead).

• Lift the mandrel with the tyre hooked and turn it

clockwise by about 15-20 cm; the tyre will position

itself sideways with respect to the rim.

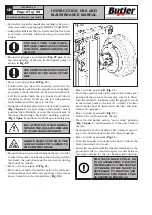

• Bring the roll holder arm in the “out of work” position

(

Fig. 18 pos. 1

); by operating on the handle control

position the roll holder arm on the internal side of

the wheel then bring it back into “working” position

(

Fig. 17 pos. 1

) and lock it with the special safety pin.

PAY ATTENTION WHEN REPOSI-

TIONING THE ROLL HOLDER ARM

TO AVOID HAND CRUSHING.

ALWAYS MAKE SURE THAT THE

ARM IS CORRECTLY LOCKED TO

THE SHIFTING BEAM.

• Mount the hook tool turned towards the tyre in order

to insert the same hook between the rim edge and the

tyre bead; the operation must be carried out during

the mandrel rotation.

• Move to work position

C

(

Fig. 11

).

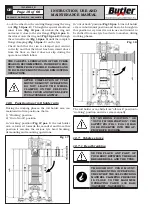

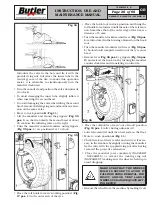

• Move the tool forward until the axis of the reference

notch matches that of the external edge of the rim at

about 5 mm from the rim itself (see

Fig. 33

).

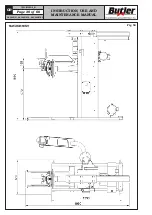

Fig. 33

• Move to work position

B

(

Fig. 11

).

• From the external side of the wheel, check the exact

position of the tool and, if necessary, correct it. Then,

turn the mandrel clockwise until the grippers reach

in the closest point to the tool (11 o’clock). The first

bead should now be inserted in the rim, therefore

remove the grippers.

• Move to work position

C

(

Fig. 11

).

• Extract the tool hook from the tyre.

• Place the roll holder arm in “out of work” position

(

Fig. 18 pos. 1

) and translate it to the outer side of

the tyre.

• Remount the hook tool with a 180° rotation, accord-

ing to the descriptions in the relevant paragraph.

• Move to work position

A

(

Fig. 11

).

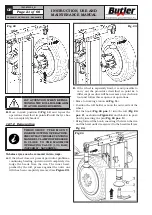

• Turn the mandrel to position the hole to insert the

valve downward (6 o’clock).

• Lower the mandrel until the wheel is laid down to the

ground in order to create the space needed between

tyre edge and rim for the air chamber introduction.

THE VALVE HOLE COULD BE

IN AN ASYMMETRIC POSITION

WITH RESPECT TO THE CENTRE

OF THE RIM. IN THIS CASE IT IS

NECESSARY TO POSITION AND

INTRODUCE THE INNER TUBE

AS SHOWN IN FIGURE 34.

7503-M002-6_B

NAV26HW - NAV26HW.S - NAV26HW.ST