34

Installation in a pipe

Type 8098 FLOWave L

8.

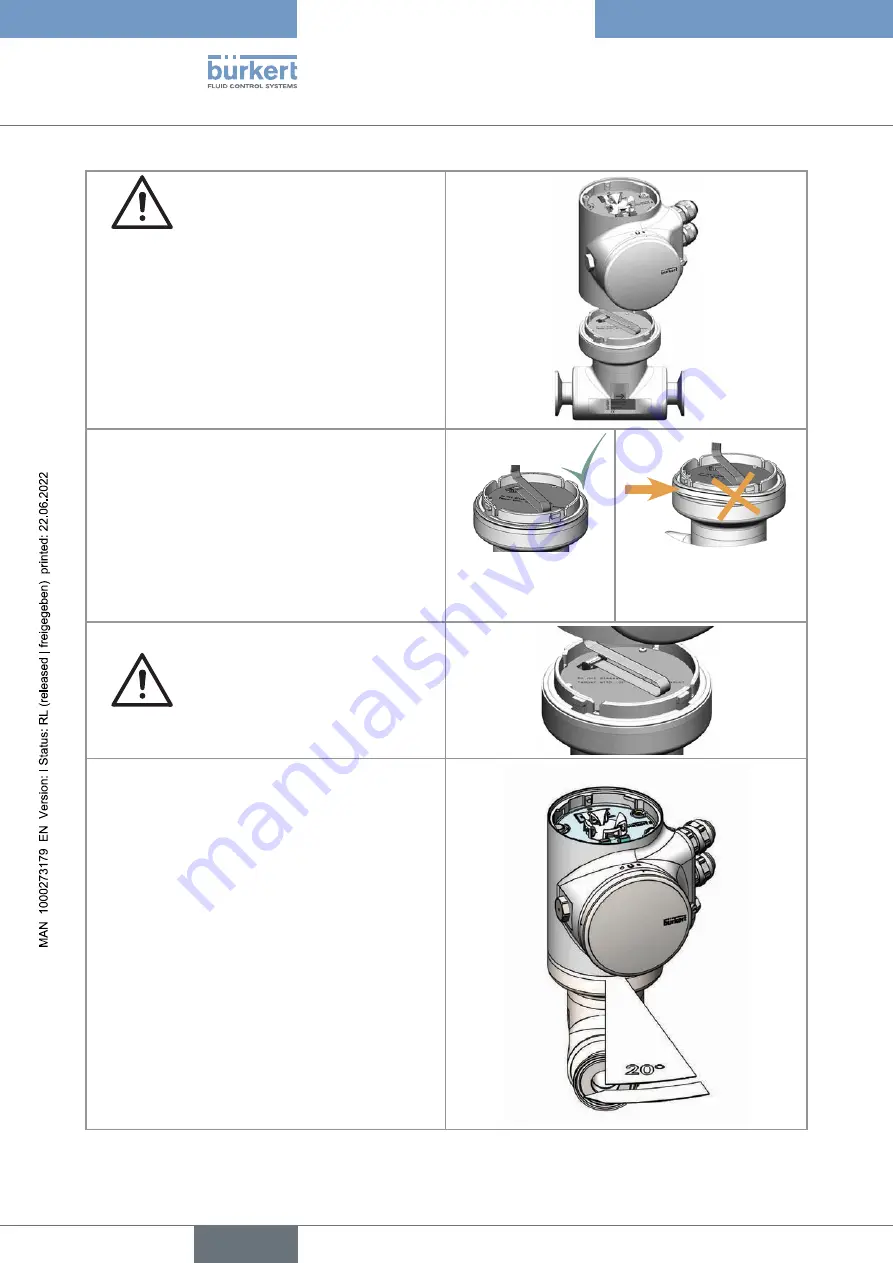

Lift the transmitter carefully because a

cable connects the transmitter to the flow sensor.

9.

If the seal is damaged, replace it. Apply a layer

of lithium soap grease to the new seal before you

put it in place.

10. If the seal is not located in the groove, put it back

in the groove.

Seal in the groove:

correct

Seal not in the

groove: NOT correct

11. Turn the transmitter to the desired position.

12.

Fold the cable in a Z-shape and make

sure the cable stays inside the transmitter.

13.

Turn the transmitter by about 20 degrees

clockwise.

English