LEARN

SMART MATRIX QUILT

2 - 36

LEARN

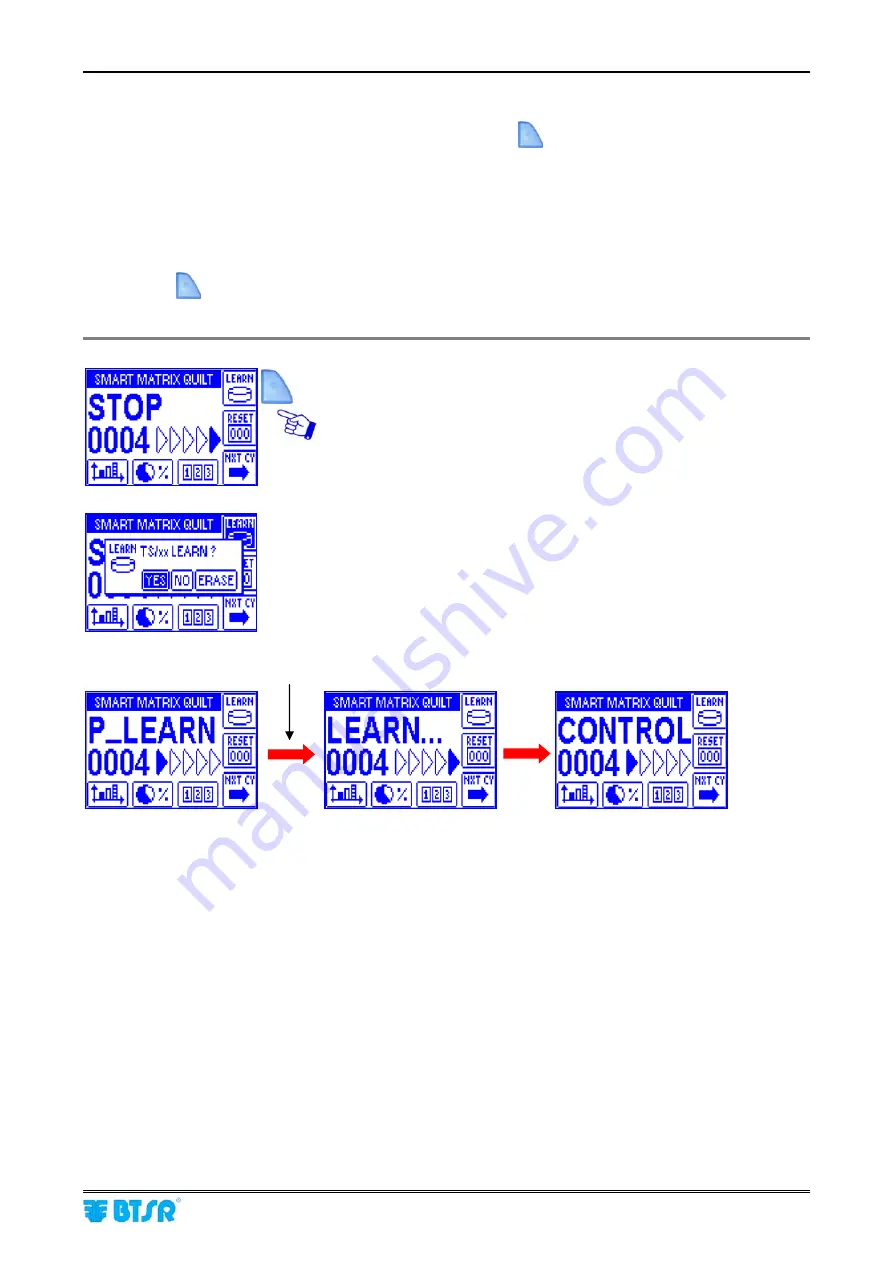

The LEARN function (which can be activated pressing the button

) allows you to carry out a learning

cycle during which the system detects and memorizes the number of sensors (nnnn) inside which the yarn is

regularly running, excluding the sensors that are detecting a tension too low.

At the end of learning cycle, after the time interval defined in Delay FAST, the system automatically activates

the Control mode and continuously controls the regular running of yarn inside all the “nnnn” sensors detected

during the learning stage.

The LEARN function must be activated while the Quilting Machine is stationary.

Pressing the

button, the LEARN function is ”reserved” (P_LEARN shown on the screen) and it will be

executed only at the machine re-start.

Press the

LEARN

activation button.

YES

to confirm

Machine re-start

Summary of Contents for SMART MATRIX QUILT

Page 1: ...SMART MATRIX QUILT Operating Manual ENGLISH Rev 1 1 January 2010 ...

Page 3: ...Introduction i ...

Page 4: ......

Page 8: ...Table of Contents SMART MATRIX QUILT iv Page left intentionally blank ...

Page 9: ...Connections and Electrical Interface 1 ...

Page 10: ......

Page 19: ...Operating Instructions 2 ...

Page 20: ......

Page 61: ...System Information 3 ...

Page 62: ......