-26-

4.

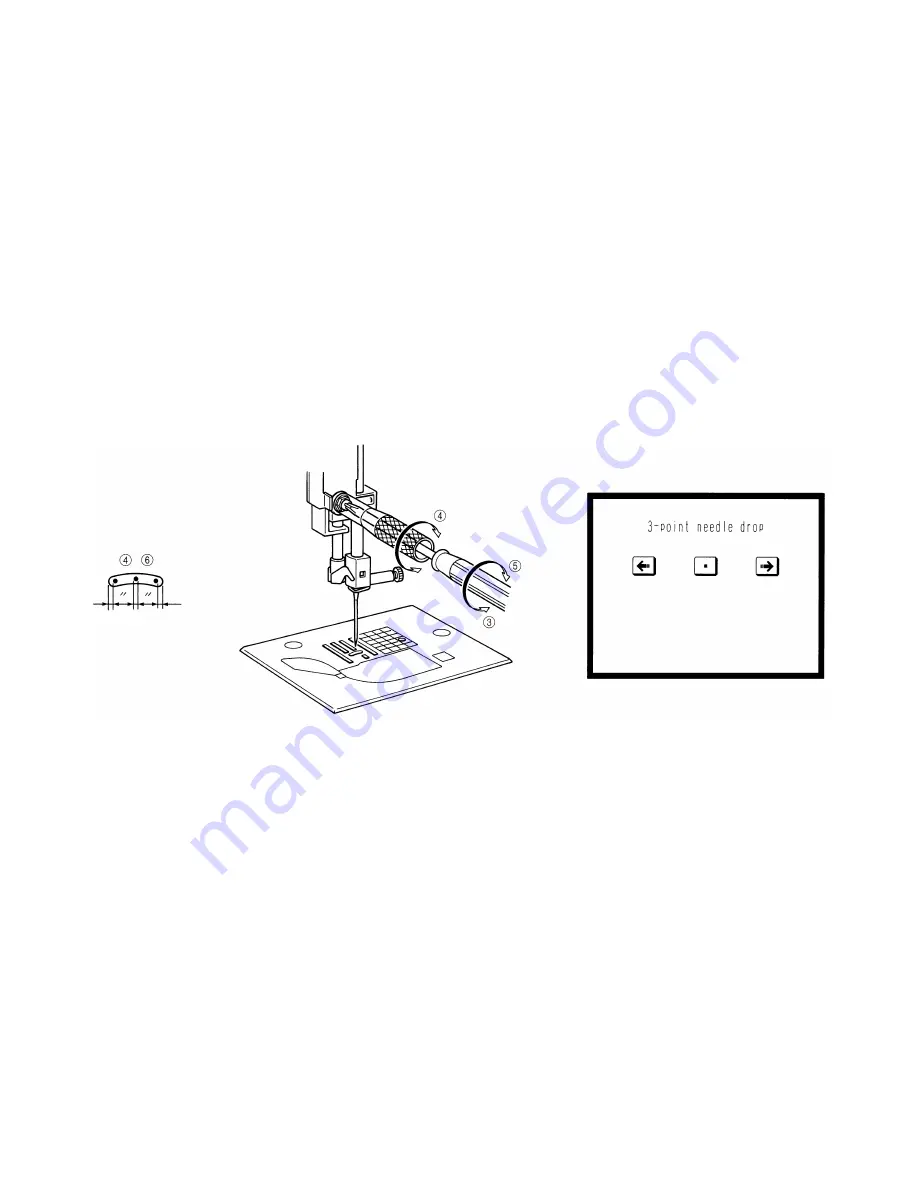

NEEDLE DOWN POSITION ADJUSTMENT

STANDARD

When test mode "4" is selected, the needle should be exactly at the middle of the needle plate hole in the needle

down position.

ADJUSTMENT

1.

Select test mode "4".

2.

Turn the balance wheel to move the needle to the needle down position.

3.

Loosen the screw securing the zigzag connecting rod assembly.

4.

Turn the balance wheel to move the needle to the left and right, and then turn the zigzag adjusting nut by using

the box wrench to set the needle in the center of the needle hole.

5.

Tighten the screw securing the zigzag connecting rod assembly.

6.

Turn the balance wheel and check the needle down position.

Summary of Contents for PC8200 SUPER GALAXIE 2000

Page 1: ...SERVICE MANUAL FOR COMPUTERIZED SEWING MACHINE PC8200 SUPER GALAXIE 2000 9 1997 ...

Page 4: ... 2 1 MECHANICAL CHART EMBROIDERY UNIT MECHANISM ...

Page 6: ... 4 3 ELECTRONIC PARTS ARRANGEMENT CHART PC 8200 Model 985 4 CONTROL SYSTEM BLOCK DIAGRAM ...

Page 16: ... 14 ...

Page 18: ... 16 ...

Page 20: ... 18 ...

Page 23: ... 21 2 LEAD WIRE ARRANGEMENT PC 8200 Model 985 ...

Page 53: ... 51 Main PC board Power supply unit ...

Page 54: ... 52 LCD unit Other PC boards 985 ...

Page 55: ... 53 PC8200 SG2000 H7070093 ...