-22-

III.

HOW TO ADJUST MECHANICAL ELEMENTS

1. POSITION OF TOUCH PANEL

(Be sure to adjust the touch panel after reconnecting the touch panel

connector.) ...........................................................................................................23

2. SETTING THE TEST MODE..................................................................................24

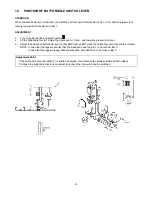

3. TENSION OF MOTOR BELT AND TIMING BELT................................................25

4. NEEDLE DOWN POSITION ADJUSTMENT.........................................................26

5. TIMING OF NEEDLE AND ROTARY HOOK

(CLEARANCE BETWEEN THE NEEDLE AND THE ROTARY HOOK POINT) ..27

6. NEEDLE BAR HEIGHT..........................................................................................28

7. LOWER SHAFT .....................................................................................................29

8. FRONT/BACK, LEFT/RIGHT POSITION OF FEED DOG ....................................30

9. HEIGHT OF FEED DOG ........................................................................................31

10. PRESSER BAR HEIGHT .......................................................................................32

11. CHECKING DETECTION OF FABRIC THICKNESS

(If a new main PC board is installed, this adjustment must be performed.) ..33

12. POSITION OF BUTTONHOLE SWITCH LEVER ..................................................34

13. BOBBIN WINDER..................................................................................................35

14. BOBBIN THREAD DETECTOR ............................................................................36

15. INNER ROTARY HOOK BRACKET POSITION ...................................................37

16. LARGE ONE-POINT PATTERN SHAPE (SOFT ADJUSTMENT)........................38

17. FEED ADJUSTMENT (VERTICAL FEED) ............................................................39

18. INNER ROTARY HOOK TENSION .......................................................................40

19. NEEDLE THREADER ............................................................................................40

20. NEEDLE THREADER

(CHECKING THE HOOK POSITION IN HORIZONTAL DIRECTION) .................41

21. NEEDLE THREADER (EXCHANGE) ....................................................................41

22. NEEDLE THREADER (CHECKING THE HOOK IN STANDARD POSITION) .....42

23. NEEDLE THREADER

(CHECKING THE HOOK POSITION IN VERTICAL DIRECTION) .......................42

24. TIMING BELT TENSION FOR THE X DIRECTION ..............................................43

25. TIMING BELT TENSION FOR THE Y DIRECTION ..............................................44

26. ADJUSTING THE X BELT PRESSER ..................................................................45

27. ADJUSTING THE Y BELT PRESSER ..................................................................45

Summary of Contents for PC8200 SUPER GALAXIE 2000

Page 1: ...SERVICE MANUAL FOR COMPUTERIZED SEWING MACHINE PC8200 SUPER GALAXIE 2000 9 1997 ...

Page 4: ... 2 1 MECHANICAL CHART EMBROIDERY UNIT MECHANISM ...

Page 6: ... 4 3 ELECTRONIC PARTS ARRANGEMENT CHART PC 8200 Model 985 4 CONTROL SYSTEM BLOCK DIAGRAM ...

Page 16: ... 14 ...

Page 18: ... 16 ...

Page 20: ... 18 ...

Page 23: ... 21 2 LEAD WIRE ARRANGEMENT PC 8200 Model 985 ...

Page 53: ... 51 Main PC board Power supply unit ...

Page 54: ... 52 LCD unit Other PC boards 985 ...

Page 55: ... 53 PC8200 SG2000 H7070093 ...