-32-

10.

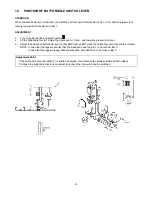

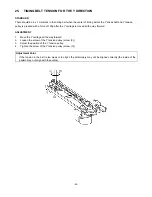

PRESSER BAR HEIGHT

STANDARD

The clearance from the needle plate top to the bottom of the presser bar should be 7.0-7.5 mm.

ADJUSTMENT

1.

Raise the presser foot lifter.

2.

Loosen the screw of the presser bar guide bracket.

3.

Adjust the height of the presser bar by moving it vertically.

4.

Tighten the screw of the presser bar guide bracket.

NOTE: The presser foot should be positioned in the center of the needle hole of the needle plate.

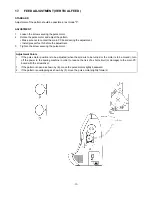

Adjustment Points

1.

Install presser foot J.

2.

When adjusting the presser bar height, the presser foot should be parallel with the feed dog hole in the needle

plate. (Refer to (A).)

*

A hexagonal pencil can be used to check the height.

3.

If the presser foot is not parallel with the feed dog hole, the needle may contact the presser foot or the fabric

may not feed straight while overcasting.

*

After the presser bar height is adjusted, be sure to adjust the fabric thickness detector using test mode "2".

Summary of Contents for PC8200 SUPER GALAXIE 2000

Page 1: ...SERVICE MANUAL FOR COMPUTERIZED SEWING MACHINE PC8200 SUPER GALAXIE 2000 9 1997 ...

Page 4: ... 2 1 MECHANICAL CHART EMBROIDERY UNIT MECHANISM ...

Page 6: ... 4 3 ELECTRONIC PARTS ARRANGEMENT CHART PC 8200 Model 985 4 CONTROL SYSTEM BLOCK DIAGRAM ...

Page 16: ... 14 ...

Page 18: ... 16 ...

Page 20: ... 18 ...

Page 23: ... 21 2 LEAD WIRE ARRANGEMENT PC 8200 Model 985 ...

Page 53: ... 51 Main PC board Power supply unit ...

Page 54: ... 52 LCD unit Other PC boards 985 ...

Page 55: ... 53 PC8200 SG2000 H7070093 ...