CHAPTER 6 TROUBLESHOOTING

6-25

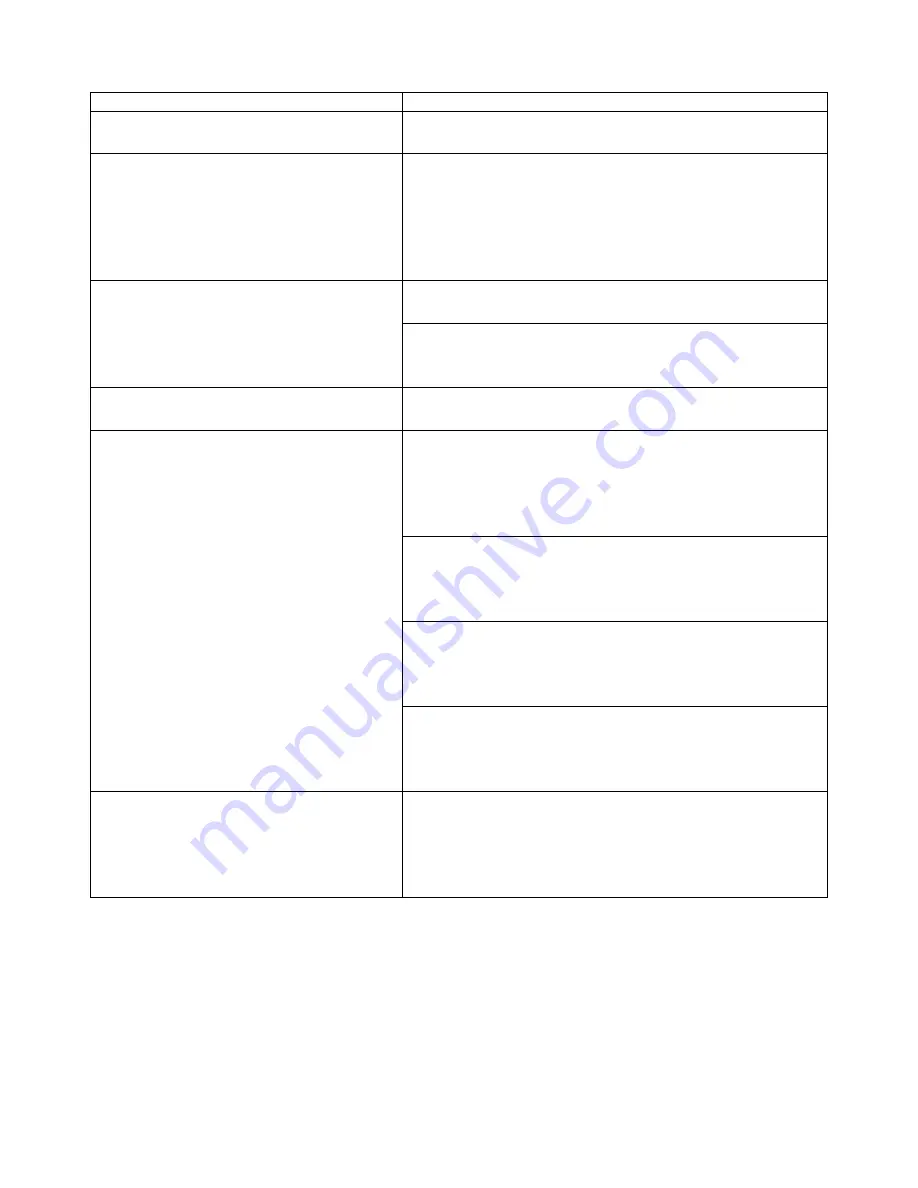

Status

Possible Causes, Descriptions, and Solutions

Print image is too dark.

Adjust image density to lighter.

See “Control Panel” in Chapter 3.

Some parts of the print image are

not clear.

Due to a sudden change in temperature,

condensation might appear inside the machine

and reduce the print quality. If this occurs when

you move the printer from a cold room to a warmer

room, don’t use the printer until it has come up to

room temperature.

Clean the Friction pad if it is dirty.

See “Cleaning the Friction Pad” in Chapter 5.

Multiple pages are fed through the

printer at once.

Clean the Pad inside the tray if it is dirty.

See “Cleaning the Pad inside the tray” in Chapter

5.

Image is printed on the reverse side

of the paper.

The paper is upside down in the tray, turn it over.

Check the paper size settings. The size specified

with the paper size dial might be different from the

actual paper size. Make the correct dial setting.

See “Changing the paper size of the paper tray” in

Chapter 1.

Use the recommended paper. Avoid using curled,

folded, or wrinkled paper, perforated paper, or

glossy paper.

See “Recommended Paper” in Chapter 1.

Confirm that the side guides and the rear guide of

the paper tray are set correctly.

See “Loading paper in the standard paper tray” in

Chapter 1.

Paper jams occur frequently.

Clean the Friction pad and the Paper feed roller, if

it is dirty.

See “Cleaning the Friction Pad” or “Cleaning the

Paper Feed Roller” in Chapter 5.

The Control panel error message

stays on after removing the jammed

paper.

Open the Front cover of your printer and then

close it. Be sure to close the lower vertical paper

feed cover.

Summary of Contents for HL-3260N

Page 4: ...IV ...

Page 27: ...CHAPTER 1 ABOUT THIS PRINTER 1 3 What is on the CD ROM Fig 1 2 ...

Page 36: ... ...

Page 52: ...1 28 5 Choose the Media Type Fig 1 25 6 Click OK 5 ...

Page 56: ... ...

Page 70: ...CHAPTER 2 BEFORE WORKING WITH THE PRINTER 2 11 Graphics Set the print quality etc Fig 2 9 ...

Page 84: ...CHAPTER 3 CONTROL PANEL 3 3 C CH HA AP PT TE ER R 3 3 C CO ON NT TR RO OL L P PA AN NE EL L ...

Page 85: ...CHAPTER 3 CONTROL PANEL 3 1 C Co on nt tr ro ol l p pa an ne el l Fig 3 1 ...

Page 88: ...USER S GUIDE 3 4 NO DATA JOB CANCELLING READY ...

Page 123: ...CHAPTER 4 OPTIONS 4 4 C CH HA AP PT TE ER R 4 4 O OP PT TI IO ON NS S ...

Page 124: ...CHAPTER 4 OPTIONS 4 1 0 0 1 2 3 G F H C D E Fig 4 1 ...

Page 135: ...4 12 0 1 2 0 1 2 3 4 5 6 0 6 7 6 2 ...

Page 151: ...4 28 0 12 3 45 2 6 0 5 0 5 2 6 6 6 0 7RESOLUTION ADAPT8 5 ...

Page 158: ...CHAPTER 4 OPTIONS 4 35 0 1 2 3 4 0 1 2 3 0 1 0 5 1 6 6 5 3 DX 5000 MX 5000 FS 5050 ...

Page 166: ...CHAPTER 4 OPTIONS 4 43 0 0 1 0 2 ...

Page 188: ...CHAPTER 5 MAINTENANCE 5 5 C CH HA AP PT TE ER R 5 5 M MA AI IN NT TE EN NA AN NC CE E ...

Page 189: ...CHAPTER 5 MAINTENANCE 5 1 Fig 5 1 ...

Page 210: ...5 22 ZAEH200E Fig 5 40 Fig 5 41 ...

Page 233: ...6 22 C CO OV VE ER R O OP PE EN N m me es ss sa ag ge e Fig 6 35 ...

Page 242: ...APPENDICES A AP PP PE EN ND DI IC CE ES S ...

Page 253: ...APPENDICES Appendix 11 0 1 0 2 3 4 42 5 5 4 5 25 0 1 0 2 ...

Page 260: ...Appendix 18 I IB BM M M Mo od de e H HP P G GL L M Mo od de e ...

Page 274: ...INDEX I IN ND DE EX X ...