Bronkhorst®

Instruction Manual IQ+FLOW® Series Digital Mass Flow / Pressure Controllers for Gases

9.17.045V

10

2.7

Analog / digital operation

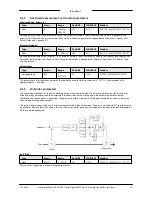

Analog operation (single channel versions only)

For analog operation refer to the “Hook-up diagram IQ

+

FLOW®” or use an RJ-45

loose-end cable (7.03.419) to connect the required signals.

Digital RS232 operation

Digital operation over RS232 can be established when

using the following setup. Using a RS232 cable or a USB-

RS232 converter with a PC will allow you to use (free)

Bronkhorst® software for Windows, such as FlowDDE and

FlowPlot. See also

section 3.4

.

Digital RS485 operation

With digital operation over RS485 a bus-system with multiple instruments can be set up. See

section 3.5

for possible

systems.

2.8

Multi-functional switch operation

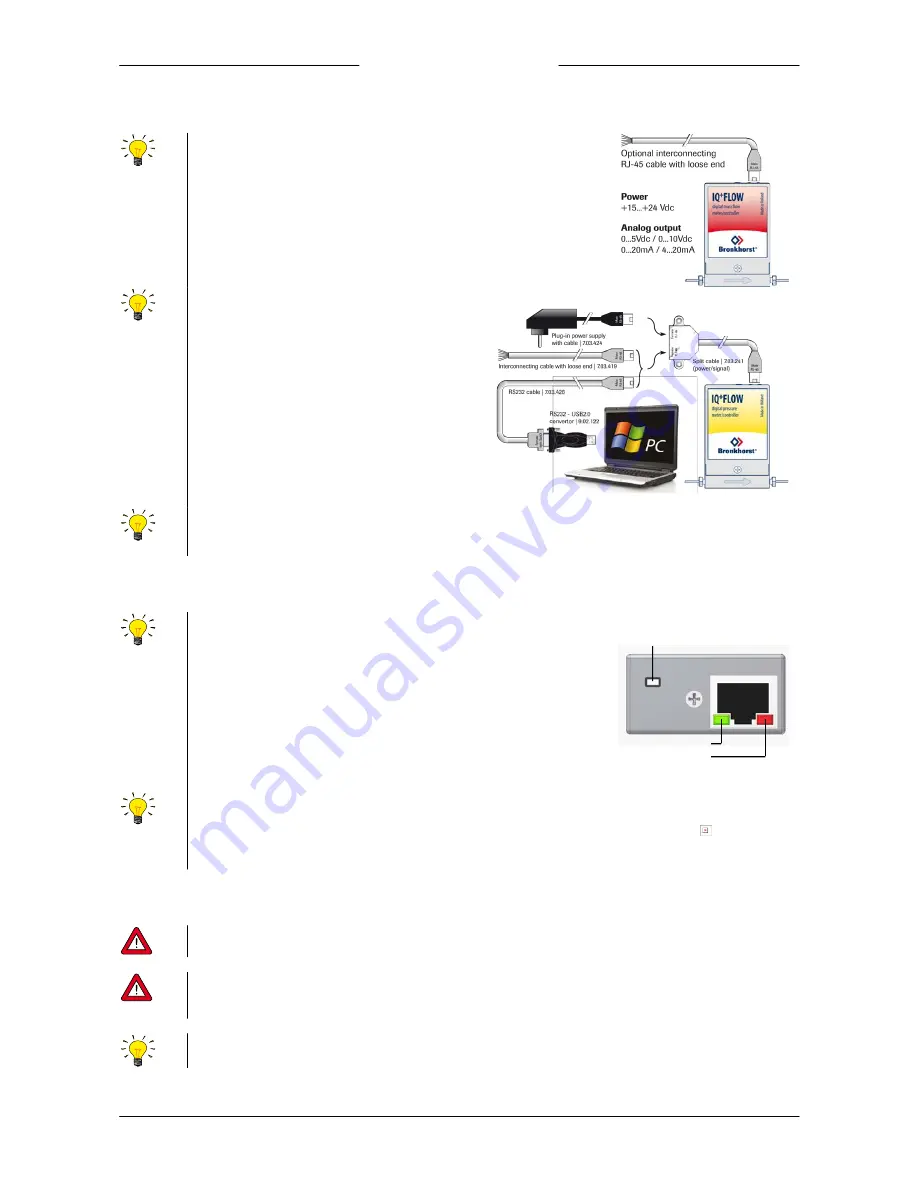

Micro-switch operation (single channel versions only)

Using the micro-switch on the instruments, several actions can be monitored and

started. The green LED is used for status indication. The red LED is used for

errors/warnings/messages. The micro-switch can be used to start several actions,

such as auto-zero, restore factory settings and bus-initialisation actions, if

applicable. See specific zero-procedure below and

section 3.3

for more details.

Multi-functional switch

Status LED

Error/Warning LED

Rotary switch operation (multi-channel versions only)

Select the communication type and Baud rate with the “COMM. TYPE” switch. Select

the node address with the “MSD” and “LSD” switch (e.g. MSD = 1 and LSD = 9 selects

node 19 for channel 1, but also node 20 and 21 for channels 2 and 3). See

section 3.3

for more details.

2.9

Purging

Do not apply pressure until electrical connections are made. When applying pressure to the system, avoid pressure shocks in

the system and increase pressure gradually. Also decrease pressure gradually when required.

In systems for use with corrosive or reactive media, purging for at least 30 minutes with a dry, inert gas (like Nitrogen or

Argon) is absolutely necessary before use. After use with corrosive, reactive or hazardous media (e.g. toxic or flammable),

purging is also necessary before the system is exposed to air.

For best accuracy, allow the IQ+FLOW® to warm up and stabilize for at least 30 minutes before starting measurement

and/or control of the fluid stream(s). This may be done with or without gas flow.