7-4

100-214-276 Rev. 3

Chapter 7: Maintenance

Periodic and Preventive Maintenance

7.2.3 Routine Component Replacement

The lifetime of certain parts is based on the number of cycles the unit has completed, or on hours

of operation.

lists the average number of hours or cycles one should use in determining

when components should be replaced. Ambient operating temperature also affects lifetime.

Higher temperatures reduce the number of cycles and hours before replacement is suggested.

The charts below are for equipment operating at a temperature of 72 to 75

o

F (22 - 24

o

C).

The lifetime of system pneumatic components is influenced by the quality of the compressed air

provided. All Branson systems require clean, dry, (normal) factory compressed air. When oil or

moisture is present in the compressed air, the lifetime of the pneumatic components will be

reduced. This table lists pneumatic parts with an average factory compressed air condition.

For Reference Purposes:

1) A system operating at 60 welds per minute, 8 hours per day, 5 days per week, 50 weeks per

year completes approximately 7.2 million cycles in 2000 hours.

2) The same system at 24 hours per day, 5 days per week, in 50 weeks completes 21.6 million

cycles in 6000 hours.

3) 24 hours per day, 365 days per year produces 31.5 million cycles in 8760 hours.

Please note that parts replaced during preventive maintenance constitute normal wear and tear.

They are not covered by warranty.

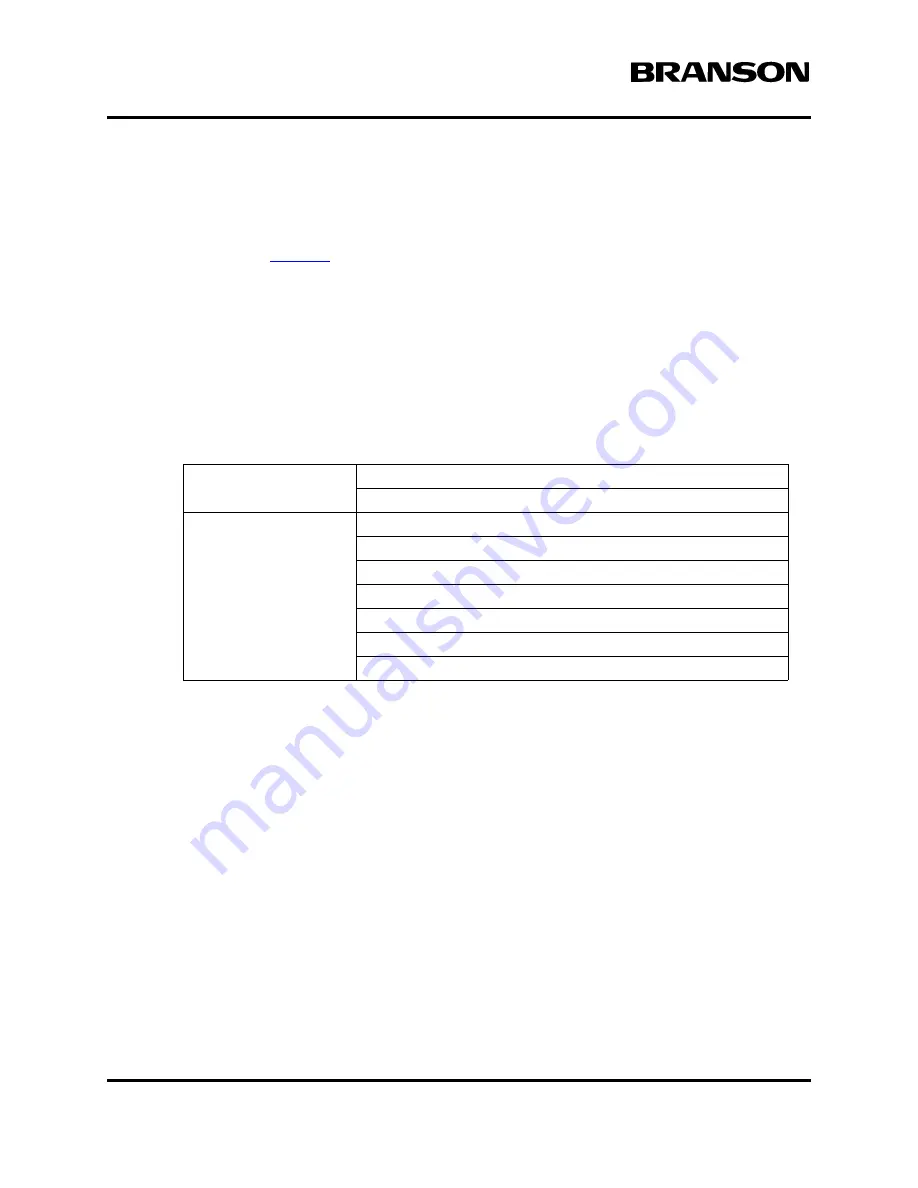

Table 7.1

Component Replacements Based on Cycles Run

At 20 Million Cycles

Base Palm Buttons

Air Cylinder

At 40 Million Cycles

Solenoid Valves

Pressure Regulator

Air Filter

Hydraulic snubber

Cooling Valve

S-Beam Load Cell Assembly

Encoder Assembly

DOC EXPIRES 12PM 7/24/2012. Article or Material must comply with the requirements

stipulated by RoHS in its current version