Operating instructions for S 40-3...S 150-3 series screw compressors

Page 21

Product description

2.2

Operating principle of compressor

Both screws have screw-shaped profiles, intermeshing without contact.

Together with the housing wall, these rotors form chambers which gradually

reduce in size along the direction of air flow. Rotation of the rotors causes the

air taken in to be compressed to the final pressure in the chambers.

During compression oil is continuously injected into the air end. This has a

cooling, sealing and lubricating function.

Air circuit

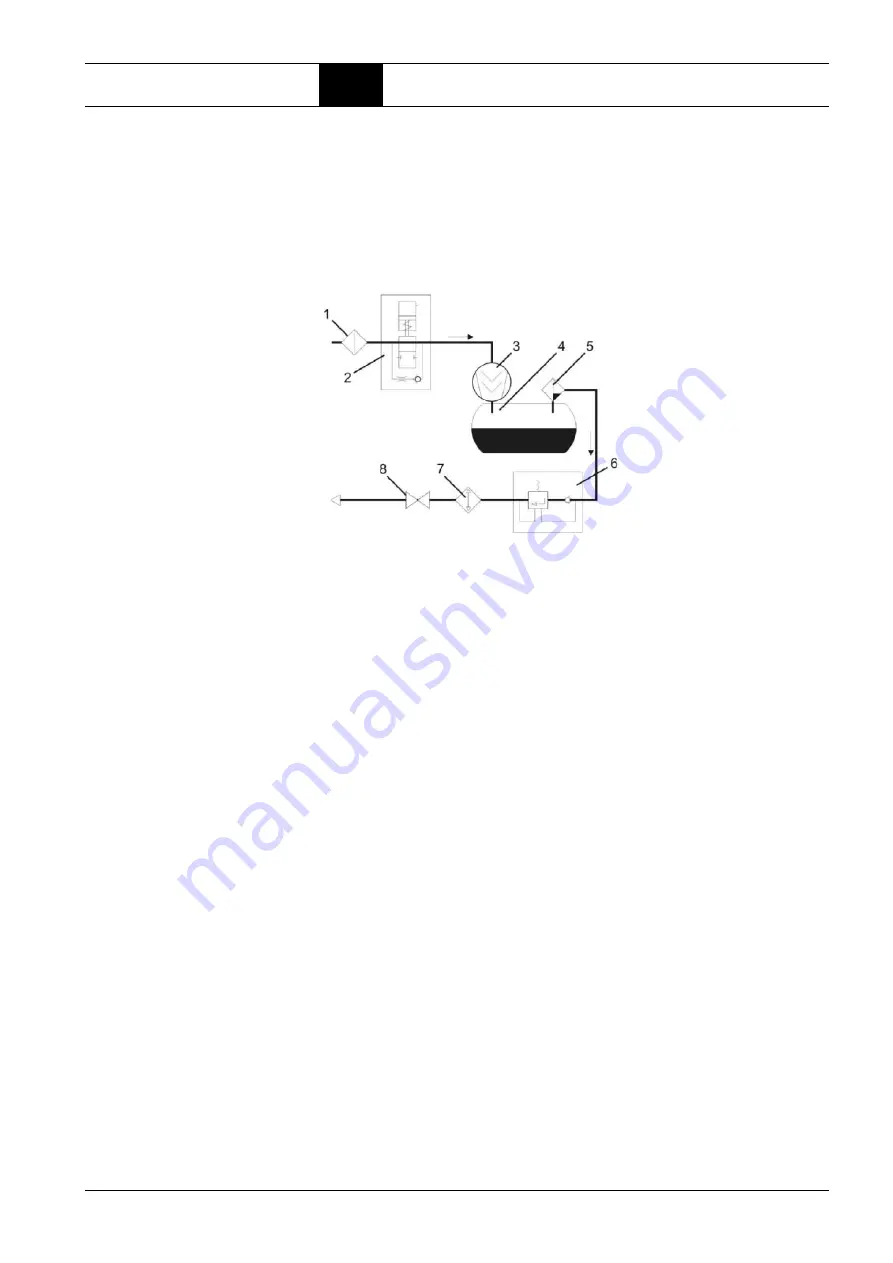

Fig. 2.1: Components of the air circuit

1 Intake filter

The intake filter cleans the air suctioned by the air end.

2 Intake regulator

The intake regulator opens (load operation) or closes (idling operation or

standstill) the suction line depending on the operating condition of the

compressor.

3 Air end

The air end compresses the air which is sucked in.

4 Compressed air-oil separator vessel

The compressed air separates from the oil under the force of gravity in the

compressed air/oil vessel.

5 Oil separator

The oil separator separates the residual oil contained in the compressed

air.

6 Minimum pressure non-return valve

The minimum pressure non-return valve does not open until the system

pressure has increased to 51 psig. This causes a rapid build-up of the

system pressure and ensures lubrication in the starting phase. Once the

compressor has been switched off, the check valve prevents the com-

pressed air from flowing back out of the mains line.

7 Compressed air aftercooler (air cooled or water cooled)

The compressed air is cooled in the compressed air aftercooler, causing

the water contained in the air to condensate.

8 Stop valve

The screw compressor can be isolated from the mains using the stop

valve.