CS6140, CS6140B Series Turning machine

Instructions

14-2

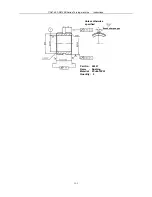

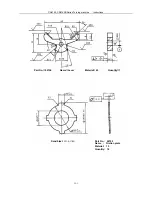

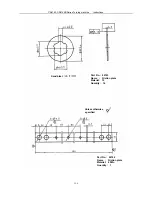

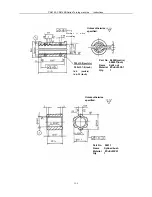

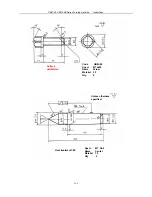

14.5 Easy-worn parts

See table 14-1 for easy-worn parts.

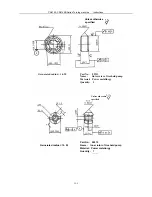

Following is a diagram of machining the easy-worn parts.

(

B16008

、

B16010

)

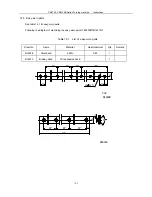

Table 14-1 List of easy-worn parts

Draw No.

Name

Material

Heat treatment

Qty.

Remark

B16008

Steel band

65Mn

C42

1

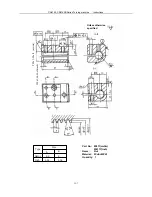

B16010

Braking band

Wire asbestos band

1

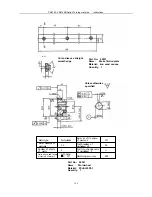

12

7

12

87

87

87

200

25

4- 6.5

87

87

87

10

620

25

90

4

C42

B16008

B16010

Summary of Contents for CS6140 Series

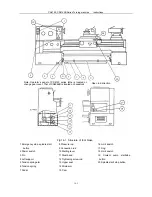

Page 16: ...CS6140 CS6140B Series Turning machine Instructions 4 3 Fig 4 2 Bearing location diagram ...

Page 31: ...CS6140 CS6140B Series Turning machine Instructions 6 2 Fig 6 1a Location of electrical parts ...

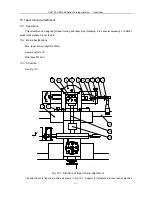

Page 33: ...CS6140 CS6140B Series Turning machine Instructions 6 4 Fig 6 2a Electric schematic diagram 1 ...

Page 34: ...CS6140 CS6140B Series Turning machine Instructions 6 5 Fig 6 2a Electric schematic diagram 2 ...

Page 48: ...CS6140 CS6140B Series Turning machine Instructions 10 2 ...