Lubrication:

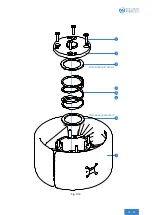

7. Lubricate the inside of the Safetyflange with oil or lubricating grease. Lubricate the following areas:

• The contact surfaces of the plain bearing washers inside the Safetyflange (surface of the Safetyflange

cone and inside of the Safetyflange cover).

• Contact surfaces of the Safetyflange cone where they touch the underlying polyamide sliding ring.

8. Reassemble the components with the desired spring (

or

) in reverse order (see

). In

order to do this, press the Safetyflange cover

down and retighten the countersunk screws

10.3 Jobs following maintenance/servicing

The following jobs must be carried out once these tasks have been completed:

STEP ACTION

1

Complete the maintenance or inspection log.

2

Check that the AIRSKIN® Safetyflange is functioning as an active safety feature. Do not approve

the machine for operation unless all the safety features including AIRSKIN® are functioning prop-

erly.

3

Assemble and secure any protective devices that have been disassembled.

4

Remove any tools, foreign parts and lubricants that have been used for maintenance.

5

Carry out a trial run of the machine.

6

In the case of maintenance without AIRSKIN® as an active safety feature: Only remove the bar-

rier tape and warning notice that clearly identify inactivity once AIRSKIN® has been tested in

operation and the machine has once again been approved for operation.

10.4 Eradication of faults

This is where you can learn what you must watch out for when eradicating faults, and where you can find the

necessary information.

In order to eradicate faults, please pay attention to the following points:

STEP ACTION

1

Ensure at all times that the machine is switched off by another person, and identify AIRSKIN® as

inactive and thus as a safety feature that is not available.

2

Also pay attention to the safety instructions in the Manual for the machine to which AIRSKIN® is

attached.

3

Only eradicate the fault if you possess the relevant qualification(s).

4

Information about the specific actions required to eradicate faults can be obtained from Blue

Danube Robotics.

5

If jobs that are being undertaken to eradicate faults are interrupted, you should ensure that all

those present are informed that the safety functions of AIRSKIN® are inactive. This should ad-

ditionally be indicated by means of barrier tapes and warning signs.