3

92

E

N

G

IN

E ASS

E

M

B

LY AN

D CO

NTRO

LS

A

B

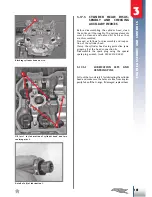

Also check the distortion of the steel discs. This

operation is done by placing the steel discs on a

perfectly flat surface and using a thickness gauge to

check that the clearance between the disc and the

surface is not greater than:

allowable distortion

steel discs: 0.10mm

3.12.3 CHECKING SPRINGS

To ensure the correct pressure between the clutch

discs, the state of the springs must be checked. The

minimum acceptable length must be:

minimum clutch spring length:

42 mm

3.12.4 CHECKING INNER HUB

The inner hub meshes with the steel clutch discs by

means of the teeth

A

: Make sure these teeth are not

meshed or shaped by abnormal wear. If so, replace

the inner hub.

Make sure that the seat

B

where the support wa

-

sher of the disc spring slides shows no traces of

meshing. If so, replace the drum.

Also control that the radial holes present on the in

-

ner hub are not obstructed and are free from sedi

-

ments.

Measuring steel disc distortion.

Clutch spring length measurement.

Checking inner hub teeth.