3

75

E

N

G

IN

E ASS

E

M

B

LY AN

D CO

NTRO

LS

2

1

3

4

10Nm

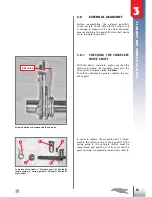

POSITIONING OF STOP CAM ON DESMODROMIC

DEVICE

1) Stop lever;

2) Stop cam;

3) Screw M6x30;

4) Movable pawl return spring.

3.8.2 ASSEMBLY OF EXTERNAL

GEARSHIFT

Keeping the stop lever moved

1

in such a way

that the spring is compressed, position the stop

cam

2

on the protruding end of the desmodro

-

mic gearshift (external right crankcase). The

stop cam has only one correct position which is

determined by the particular shape of the end

of the desmodromic device and of the bottom

part of the stop cam.

Proceed mounting the tightening screw

3

M6x30 between the stop cam and the desmo

-

dromic gearshift, after having applied medium-

resistance sealant: tighten it at 10Nm.

Insert the drive shaft together with the washer

in its seat keeping the return spring

4

of the

movable pawl pressed.

Wishing to test the correct functioning of the

entire unit, you just need to temporarily cou

-

ple the external gearshift lever and to simula

-

te the operation of changing gears, by lifting

and lowering the gearshift lever and having the

mainshaft of the gear unit rotate. The whole de

-

vice works properly if abnormal jamming does

not occur.

If the unit runs without oil, the device makes

more noise than usual.

3.9

KICK StARtER

Before coupling the kickstarter to the crankcase

half, some controls must be carried out.

3.9.1 CHECKING KICKSTARTER

SHAFT UNIT AND ASSEM-

BLY

In order to disassemble all the parts of the

kickstart shaft, pull off the washer

11

at the end

of the shaft (on the side of the spring

16

), the

spring

16

, the kickstart sleeve

14

, and the lever

return spring

8

, which to be unfastened from

the shaft must be pulled in the radial direction

so that it is extracted from its hole. Pull out the

kickstart spacer

9

.