GYRO WRAP™

Signature

®

Series

14

Belanger, Inc. * PO BOX 5470 *Northville, MI 48167-5470 * Ph (248) 349-7010 * Fax (248) 380-9681

1MANUL248

Installation

Tunnel Placement

When placing a piece of equipment, tunnel depth will vary from site to site. Be sure to allow an

adequate operating envelope when installing. Use the physical dimensions from pages 9 and 10 to

help determine placement.

Do all work in the approximate area where you will permanently place the Gyro Wrap™.

Frame Assembly

1) Measure, square up, and run a chalk line down the center of the wash bay relative to the doors or

entrance as shown below. The actual length down the bay will vary from site to site. Write down this

dimension from your site plan drawings.

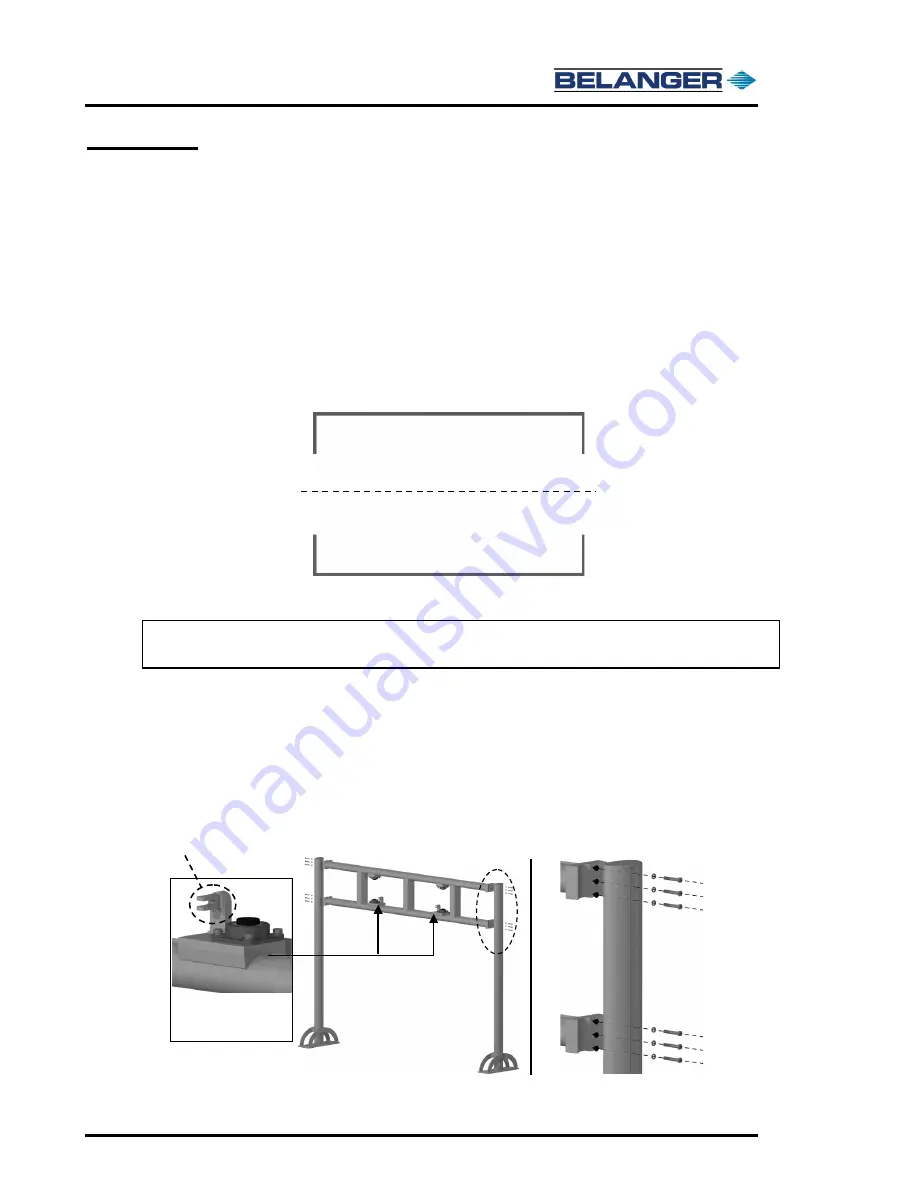

2) Using a forklift and two C-clamps, secure the forks to the head beam assembly as shown.

3) Remove the head beam assembly from the skid.

4) Remove the shipping legs from the head beam assembly but do not discard the fasteners and lock

washers.

5) Remove both leg assemblies from the skid and secure them to the head beam assembly as shown in

the images below. You will use the same fasteners and lock washers that attached the shipping legs

to the head beam assembly.

6) Locate the accessory box and remove the eight 5/8 x 6” concrete lag bolts.

Note:

Use protective material between the forks and the head beam assembly to ensure that the

powder coating does not get scratched.

Be sure that the

cylinder Clevises are

on the bottom

Clevis