List of attachments

50

DRYPOINT RA 200 – 2500 NA

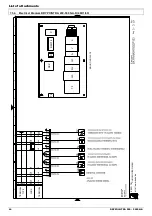

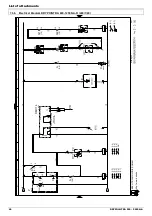

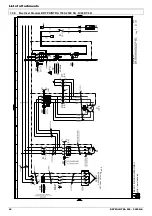

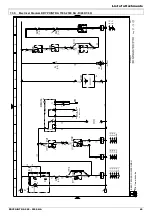

7.3.10. Electrical Diagram DRYPOINT RA 1500-2500 NA -R (460/1/60)

0

1

3

2

4

5

6

7

8

9

R

e

v

:

D

ra

w

in

g

n

o

.

:

P

a

g

/

B

E

K

O

T

E

C

H

N

O

L

O

G

IE

S

G

M

B

H

h

tt

p

:/

/

w

w

w

.b

e

k

o

.d

e

FA

N C

ON

TR

OL

P

RE

SS

. S

WIT

CH

-

LO

W S

PE

ED

FA

N D

OO

R I

NT

ER

LO

CK

S

AF

ET

Y-S

WIT

CH

AIR

C

OO

LE

D O

NL

Y -

J

UM

P I

F N

OT

IN

ST

AL

LE

D

TIM

ED

D

RA

IN

O

UT

PU

T

NO

T U

SE

D

RE

MO

TE

A

LA

RM

O

N I

ND

IC

AT

IO

N

FA

N T

HE

RM

AL

P

RO

TE

CT

IO

N

AIR

C

OO

LE

D O

NL

Y -

J

UM

P I

F N

OT

IN

ST

AL

LE

D

SA

FE

TY

P

RE

SS

UR

E S

WIT

CH

CO

MP

RE

SS

OR

D

IS

CH

AR

GE

(H

IG

H)

SID

E

SA

FE

TY

P

RE

SS

UR

E S

WIT

CH

FA

N C

ON

TR

OL

P

RE

SS

. S

WIT

CH

-

HIG

H S

PE

ED

AIR

C

OO

LE

D O

NL

Y

AIR

C

OO

LE

D O

NL

Y

2x

B

EK

OM

AT

D

RA

IN

ER

CO

MP

RE

SS

OR

S

UC

TIO

N (

LO

W)

SID

E

ma

x 2

50

V 1

A -

m

in

5

VD

C 1

0m

A

Q

1

K

SE

Z

A

V

2

V

1

Q

2

Q

3

Q4

OP

TIO

NA

L -

T

R T

RA

NS

FO

RM

ER

-

46

0V

S

ID

E

CO

NN

EC

T T

O S

EZ

F

OR

3

/4

60

/6

0 P

OW

ER

S

UP

PL

Y

DE

W-P

OIN

T P

RO

BE

CO

MP

RE

SS

OR

C

RA

NK

CA

SE

H

EA

TE

R

R

S

D

P

V

1

P

A

P

B

P

V

2

T

V

T

S

M

O

U

N

T

IN

G

P

L

A

T

E

T

F

7 -

8

5 -

6

3 -

4

T1

1 -

2

T

S

R

11

-

12

9 -

1

0

19

-

20

15

-

16

13

-

14

17

-

18

14

17

15

1

T1

T1

T

E

R

M

IN

A

L

wh

ite

W

IR

E

re

d

12

11

10

9

15

16

5

8

14

2

3

4

6

7

13

26

12

23

22

31

12

23

14

-

27

35

UK

K 5

UK

K 5

T

Y

P

E

T

E

R

M

IN

A

L

R

T

S

19

20

18

R

12

30

12

T

S

UK

6N

E

L

D

Summary of Contents for DRYPOINT RA 1000/AC NA

Page 37: ...List of attachments DRYPOINT RA 200 2500 NA 37 7 2 2 Exploded view DRYPOINT RA 200 350 NA ...

Page 38: ...List of attachments 38 DRYPOINT RA 200 2500 NA 7 2 3 Exploded view DRYPOINT RA 400 500 NA ...

Page 39: ...List of attachments DRYPOINT RA 200 2500 NA 39 7 2 4 Exploded view DRYPOINT RA 600 1250 NA ...

Page 40: ...List of attachments 40 DRYPOINT RA 200 2500 NA 7 2 5 Exploded view DRYPOINT RA1500 2500 NA ...

Page 51: ...List of attachments DRYPOINT RA 200 2500 NA 51 ...