Maintenance, troubleshooting, spares and dismantling

24

DRYPOINT RA 200 – 2500 NA

6. Maintenance, troubleshooting, spares and dismantling

6.1.

Controls and Maintenance

DANGER!

Compressed air, mains voltage, unqualified personnel!

Only qualified personnel should perform troubleshooting and or maintenance operations.

Prior to performing any maintenance or service, be sure that:

no part of the machine is powered and that it cannot be connected to the mains supply.

no part of the machine is under pressure and that it cannot be connected to the compressed air

system.

Maintenance personnel have read and understand the safety and operation instructions in this

manual.

Before attempting any maintenance operation on the dryer, shut it down and wait at least 30 minutes.

DANGER!

Hot surfaces!

Some components can reach high temperature during operation. Avoid contact until system or component

has dissipated heat.

DAILY:

Verify that the DewPoint displayed on the electronic instrument is correct.

Check the proper operation of the condensate drain systems.

Verify the condenser for cleanliness.

EVERY 200 HOURS OR MONTHLY

With an air jet (max. 2 bar / 30 psig) blowing from inside towards outside clean the

condenser; repeat this operation blowing in the opposite way; be careful not to

damage the aluminium fins of the cooling package.

•

At the end, check the operation of the machine.

EVERY 1000 HOURS OR YEARLY

•

Verify for tightness all the screws of the electric system and that all the “Faston” type connections are in their

proper position, inspect unit for broken, cracked or bare wires.

•

Inspect refrigerating circuit for signs of oil and refrigerant leakage.

•

Measure and record amperage. Verify that readings are within acceptable parameters as listed in specification

table.

•

Inspect condensate drain flexible hoses, and replace if necessary.

•

At the end, check the operation of the machine.

Summary of Contents for DRYPOINT RA 1000/AC NA

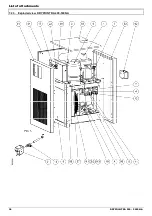

Page 37: ...List of attachments DRYPOINT RA 200 2500 NA 37 7 2 2 Exploded view DRYPOINT RA 200 350 NA ...

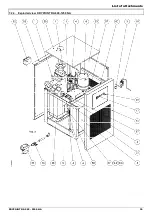

Page 38: ...List of attachments 38 DRYPOINT RA 200 2500 NA 7 2 3 Exploded view DRYPOINT RA 400 500 NA ...

Page 39: ...List of attachments DRYPOINT RA 200 2500 NA 39 7 2 4 Exploded view DRYPOINT RA 600 1250 NA ...

Page 40: ...List of attachments 40 DRYPOINT RA 200 2500 NA 7 2 5 Exploded view DRYPOINT RA1500 2500 NA ...

Page 51: ...List of attachments DRYPOINT RA 200 2500 NA 51 ...