Maintenance, troubleshooting, spares and dismantling

26

DRYPOINT RA 200 – 2500 NA

DewPoint too low.

The fan is always ON - PV pressure switch is faulty - replace it (Air-Cooled).

The Hot Gas By-pass Valve is out of setting - contact a refrigeration engineer to restore the

nominal setting.

Excessive pressure

drop within the dryer.

The dryer doesn’t drain the condensate - see specific point.

The DewPoint is too low - the condensate is frost and blocks the air - see specific point.

Check for throttling the flexible connection hoses.

The dryer doesn’t drain

the condensate.

The condensate drain service valve is closed - open it.

Verify the electric wiring.

The DewPoint is too low - the condensate is frozen - see specific point.

Bekomat drainer is not operating correctly – (see BEKOMAT MANUAL)

The dryer continuously

drains condensate.

Bekomat drainer is dirty – (see BEKOMAT MANUAL)

Water within the line.

The dryer doesn't start - see specific point.

Where installed - Untreated air flows through the by-pass unit - close the by-pass.

The dryer doesn’t drain the condensate - see specific point.

DewPoint too high - see specific point.

The safety thermo-

switch T

S

tripped.

Check which of the following has caused the activation :

1. Excessive thermal load – restore the standard operating conditions.

2. The inlet air is too hot - restore the nominal conditions.

3. The ambient temperature is too high or the room aeration is insufficient - provide proper

ventilation.

4. The condenser unit is dirty - clean it.

5. The fan doesn’t work - see specific point.

6. There is a leak in the refrigerating fluid circuit - contact a refrigeration engineer.

7. Reset the thermo-switch by pressing the button on the thermo-switch itself – verify the

correct operation of the dryer.

8. The TS thermo-switch is faulty - replace it.

The P

A

high-pressure

switch has been

activated.

Check which of the following has caused the activation :

1. The ambient temperature is too high or the room aeration is insufficient - provide proper

ventilation (Air-Cooled).

2. The condenser is dirty - clean it (Air-Cooled).

3. The condenser fan doesn’t work - see specific point (Air-Cooled).

4. The cooling water is too hot - restore the nominal condition (Water-Cooled).

5. The cooling water flow is insufficient - restore the nominal condition (Water-Cooled).

6. Reset the pressure-switch pressing the button on the controller itself - verify the dryer for

correct operation.

7. The PA pressure switch is faulty - contact a refrigeration engineer to replace it.

The P

B

low-pressure

switch has been

activated.

There is a leak in the refrigerating fluid circuit - contact a refrigeration engineer.

The pressure switch restores automatically when normal conditions are restored - check

the proper operation of the dryer.

The “alarm” led is ON.

The P

A

high-pressure switch is activated - see specific point.

The P

B

low-pressure switch is activated - see specific point.

The electric protection (see Q1 on the electric diagram) of the compressor is activated -

restore it and retry.

The electric protection (see Q2 on the electric diagram) of the fan(s) is activated - restore it

and retry (air cooled).

The thermal protection (see TV on the electric diagram) inside the fan is activated - wait 30

minutes and retry.

The safety thermo-switch T

S

has been activated - see specific point.

DMC14- The LED

of the

instrument is on or

flashes to indicate

alarm situations.

The LED

flashes because the DewPoint is too high – see specific point.

The LED

flashes because the DewPoint is too low - see specific point.

The LED

flashes because the probe is faulty or interrupted, the instrument displays

the message “PF” (Probe Failure) – replace the probe.

Summary of Contents for DRYPOINT RA 1000/AC NA

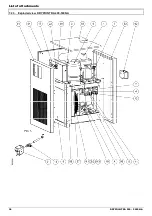

Page 37: ...List of attachments DRYPOINT RA 200 2500 NA 37 7 2 2 Exploded view DRYPOINT RA 200 350 NA ...

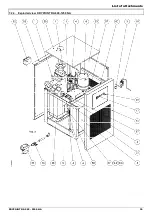

Page 38: ...List of attachments 38 DRYPOINT RA 200 2500 NA 7 2 3 Exploded view DRYPOINT RA 400 500 NA ...

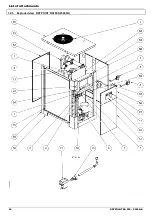

Page 39: ...List of attachments DRYPOINT RA 200 2500 NA 39 7 2 4 Exploded view DRYPOINT RA 600 1250 NA ...

Page 40: ...List of attachments 40 DRYPOINT RA 200 2500 NA 7 2 5 Exploded view DRYPOINT RA1500 2500 NA ...

Page 51: ...List of attachments DRYPOINT RA 200 2500 NA 51 ...