5

www.bdsensors.de

ASM 400

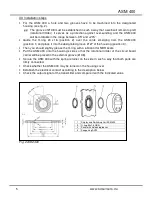

3.3 Installation steps

•

For the ASM 400, a hole and two grooves have to be machined into the designated

housing (see fig. 2).

The groove of Ø 38 must be established in such a way that a web will remain top left

(rotational limiter). It serves as a protection against over-winding, and the ASM 400

will be rotatable in the range between -35° and +215°.

•

Guide the O-ring 24 x 1.6 (position 2) over the cords emerging from the ASM 400

(position 1) and place it into the designated groove Ø 27 of the housing (position 3).

•

Then you should slightly grease the O-ring with a lubricant for NBR seals.

•

Put the ASM 400 onto the housing’s side so that the rotational limiter of the circuit board

carrier will be placed in the external groove (Ø 38).

•

Secure the ASM 400 with the spring retainer on the side in such a way that both parts are

firmly connected.

•

Check whether the ASM 400 may be turned on the housing cover.

•

Establish the electrical contact according to the description below.

•

Check the output signal of the transmitter and compare it with the indicated value.

Fig. 2 ASM 400

1

Display and Switching Unit ASM 400

2

O-ring 24x1.6 NBR

3

Panel with hole and grooves

4

Seegerring AV20

Summary of Contents for ASM 400

Page 18: ...ASM 400 Dimensions...

Page 19: ...19 www bdsensors de ASM 400...