ASM 400

1.5 Package contents

Please verify that all listed parts are included in the delivery:

•

Display and Switching Unit ASM 400

•

O-ring 24x1.6 NBR

•

Retaining ring (Seegerring AV20)

•

Sheet of labels

•

Operating Manual "ASM 400"

2. Product identification

The device can be identified by its type plate. It provides the most important data. By the

ordering code the product can be clearly identified.

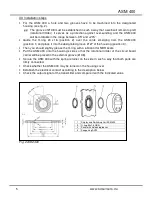

Fig. 1 Type plate

For identification of the firmware, the program version (e. g. P07) will appear for about 1 second

in the display after starting up the device. Please hold it ready for inquiry calls.

3. Installation

3.1 General notes

•

Please note that this device is a precision electronic instrument. Handle the device careful-

ly to avoid damages to the plastic surface and housing parts.

•

The display and the plastic housing are equipped with a rotational limiter. Please do only

rotate the display or the housing within the limit.

•

The ingress protection by factory is IP 00 (front side: IP 65). The ingress protection of the

total appliance depends on the housing mounted by the customer.

3.2 Necessary utilities

•

O-ring 24x1.6 NBR - is included in the scope of delivery -

•

retaining ring (Seegerring AV20) - is included in the scope of delivery -

•

grease for seals of NBR

•

soldering iron, soldering grease and tin-solder (if the electrical connection should be made

by soldering)

•

crimping tool and a compatible plug connection (if the electrical connection should be

pluggable)

•

seeger circlip pliers

•

devices for simulation of the measuring range (e. g. pressure calibrator) and for measuring

the output signal (digital multimeter)

•

device for checking the contact functions

Ordering code

Type

designation

Serial number

Pin configuration

Summary of Contents for ASM 400

Page 18: ...ASM 400 Dimensions...

Page 19: ...19 www bdsensors de ASM 400...