Operator Manual for the Baxter ExactaMix 2400 Compounder

Page 202

53007410 Rev. C

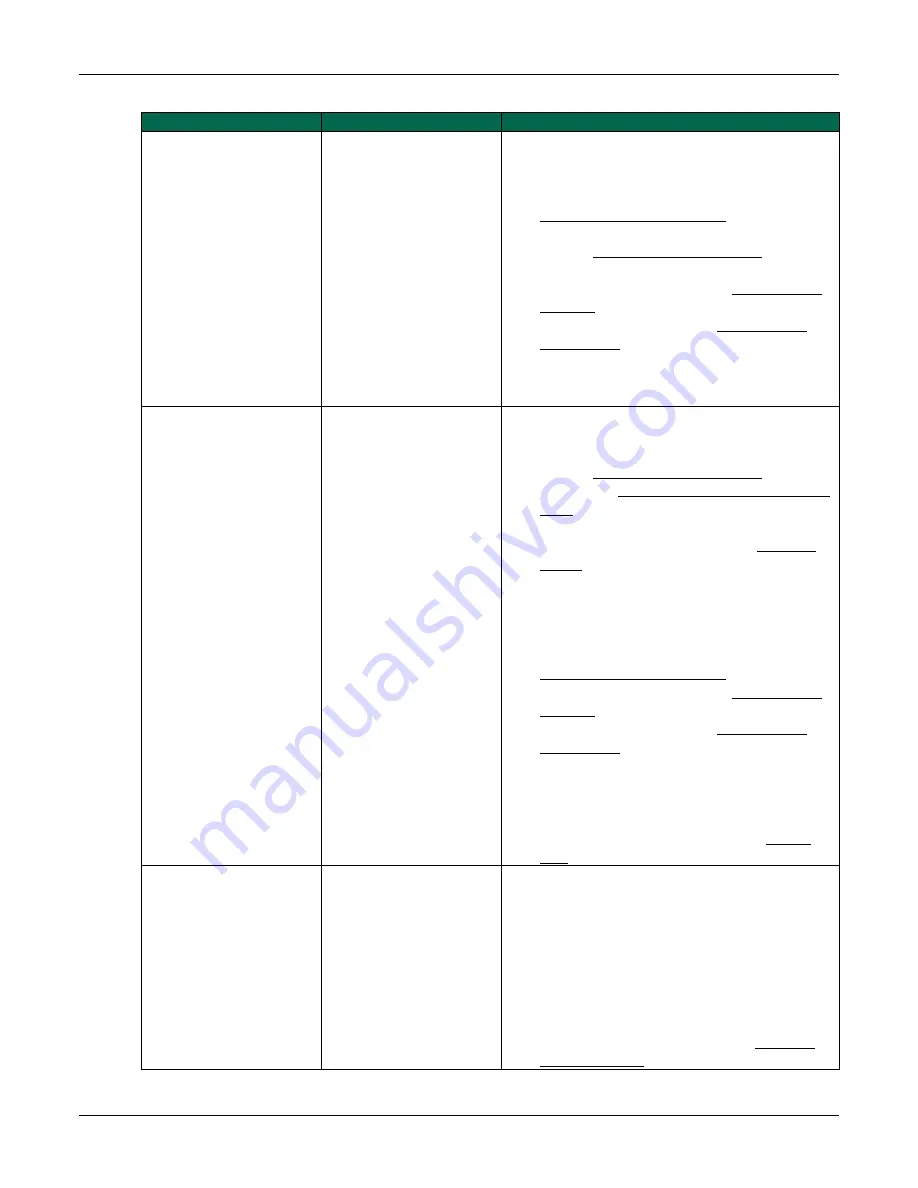

Issues with the Weight and Load Cell

On-screen Text

Explanation

Suggested Actions

Expected Weight:

<

calculated weight

> gm

Actual Weight: <

actual

weight

> gm

Difference: <

weight

difference

>%

The final weight of this

solution is outside of the

acceptable limit of +/-5%

Possible Cause: Unknown

The final bag weight is out

of range.

After the compounder

delivers all the

ingredients, the weight of

the patient bag differs

from the expected weight

by more than the

acceptable difference.

1.

Check that all the source containers are spiked

properly. Refer to the steps for spiking a

container, starting on Page 51.

2.

Check that the pump rotor is clean. Refer to

CLEANING THE COMPOUNDER on Page 101.

3.

Check that the outlet tube is installed properly.

Refer to Installing the New Valve Set on

Page 45.

4.

Calibrate the load cell. Refer to Calibrating the

5.

Calibrate the pump. Refer to Calibrating the

Compounder on Page 69.

6.

Compound a large-volume solution with at

least 205 mL of water to make the compounder

calibrate automatically.

Expected Weight:

<

calculated weight

> gm

Actual Weight: <

actual

weight

> gm

Difference: <

weight

difference

>%

The final weight of this

solution is within the

acceptable limit of +/-5%,

however some

ingredients may not have

delivered correctly.

Possible Cause:

<

ingredient name

> is

possibly <

underweight /

overweight

> by <

weight

error

> grams

An individual ingredient

delivery is out of range.

After the compounder

delivers an ingredient, the

weight of the patient bag

differs from the expected

weight by more than the

acceptable difference.

The compounder checks

the weight after individual

ingredient deliveries over

100 mL.

1.

Check that all the ingredients and inlets are

correct.

2.

Check that the tube set is installed properly.

Refer to Installing the New Valve Set on

Page 45 and Attaching the New Ingredients and

3.

On the MixCheck Report, check for references

to occlusions and bubbles. Refer to MixCheck

Report on Page 161. Have a pharmacist check

the accuracy.

4.

Check that all the source containers are spiked

properly. Refer to the steps for spiking a

container, starting on Page 51.

5.

Check that the pump rotor is clean. Refer to

CLEANING THE COMPOUNDER on Page 101.

6.

Calibrate the load cell. Refer to Calibrating the

7.

Calibrate the pump. Refer to Calibrating the

Compounder on Page 69.

8.

Compound a large-volume solution with at

least 205 mL of water to make the compounder

calibrate automatically.

9.

Contact Baxter Technical Services to check that

the flow factors are correct. Refer to Getting

Bag out of range

Dextrose is pumping too

quickly or slowly.

1.

Check that there are no environmental factors

interfering with pumping dextrose.

•

Keep the room temperature stable.

•

Always allow refrigerated dextrose to return

to room temperature before using it.

2.

Check that the source container is spiked

properly. Refer to the steps for spiking a

container, starting on Page 51.

3.

Check that the correct inlet is assigned to

dextrose in the formulary. Refer to Adding or

Editing a Product on Page 143.

Summary of Contents for ExactaMix 2400 Compounder

Page 2: ......