Operating Manual for

Bauer Separator Compact

27

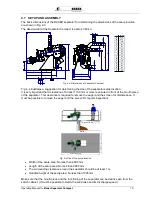

13.3 INSPECTING AND REINSTALLING THE SCREEN

The wearing of the screen occurs primarily in

the area where the auger blades end in the

screen, i.e. at the transition to the pressing

area of the separator. If a sharp-edged transi-

tion can be seen in this area (Fig. 13-8 left),

the screen was not installed again correctly

after the previous inspection. In this case, the

screen was damaged due to insufficient float-

ing capacity.

When you reinstall the screen, make sure that

the triangle stamped into the guide rod of the

screen is

“

up

”

[12 o

’

clock position], see also

Fig. 13-9. If this original installation position is

retained, it is possible to identify the causes

for any uneven wear on the basis of wear

marks.

The screen must have sufficient floating capacity after reinstallation; in other words, it must not be un-

der axial tension from the housing and the mouthpiece. If installed correctly, the screen can be moved

somewhat by hand. A small gap of several tenths of a millimeter must exist between the mouthpiece

and the screen. This must be checked with a thickness gage (Fig. 13-10).

Fig.13-8 Wear in the screen due

to screen under tension (left)

Normal screen wear (right)

Inspection of the floating capacity with the

thickness gage

Fig. 13-10 Movable screen in the separator,

inspection of the floating capacity by hand

(left)

Fig.13-9 Sieve installation position, stamped triangle at top and

toward the front of the separator