Operating Manual for

Bauer Separator Compact

23

10

LIQUID CLEANING

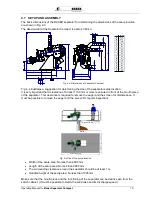

Fig. 10-1 illustrates the arrangement of 2 separators in series, where the effluent of the first separator

is supplied to the second separator. The second separator is equipped with screens of a smaller gap

width than the first separator in order to achieve a further clarifying of the liquid.

11

IMPORTANT ASPECTS TO BE CONSIDERED DURING OPERATION

Check the output of the pump to ensure that the overflow

“

bypass

”

is only half full.

Inspect the pump to ensure that the operating pressure on the seal of the auger drive does not

exceed 2 m water column.

Make certain that no pipelines are pressed together and no negative pressure arises in the

supply system.

The higher the DM content in the input material, the better the separation will be if the input

medium is homogenized. If the solid concentration of the input medium declines significantly,

check the solid cake by returning some of the separated solid to the separation process.

Under normal conditions, the arms of the output regulator

“

breathe

”

somewhat; in other words,

they move up and down a little. If the up and down movement of the arms is too large, you

must increase the contact pressure by increasing the number of the weights or their leverage. If

the contact pressure becomes too high, the solid cake will become too hard [see section 14

“

Problems - Troubleshooting

”

].

12

TAKING THE SEPARATOR OUT OF OPERATION

1. Switch off the feed pump to the separator.

2. Allow the separator to continue running for about 30-60 seconds until no more solid or separated

slurry is discharged, then switch it off.

Depending on the type of medium being separated, the separator may sit unused for up to a week

or more without the need to remove the solid cake.

3. For longer periods of disuse, the cake should be removed and the separator cleaned. To remove

the cake, open the lid and break up the cake by hand.

4. If the separator is also used in freezing temperatures, it should be ensured after operation that all

supply and return pipes as well as the separator itself are completely emptied in order to prevent

freezing of the slurry. If the cake is frozen solid in the separator, it must be thawed with hot water

before restarting.

Fig. 10-1 Typical arrangement for the operation of 2 separators in series

Inflow