24

Operating Manual for

Bauer Separator Compact

S

13

MAINTENANCE AND INSPECTION

13.1 GEARBOX AND MOTOR

The gearbox and motor are delivered ready for operation. They are filled with the required volume of oil

and

maintenance-free

. After approx. 10,000 operating hours, but no later than every 2 years, the oil

must be changed and the bearing inspected; details on this work can be found in the gearbox and mo-

tor documentation.

Perform a daily visual inspection during operation to ensure that the seals of the gearbox and machine

are tight.

Check the oil level of the gearbox roughly twice per year. Other than a regular supply of sealing medi-

um, the Bauer separator normally requires little maintenance.

13.1.1 Supply with Sealing Medium

NOTE

It must be ensured that the used sealing media and greases are compatible with

the seals (FPM material). Greases of viscosity class 2 are used as standard, such

as Alvania EP 2 from Shell, Beacon EP 2 from Esso or Aralub HLP 2 from Aral.

On a separator in operation, it is important to supply seal-

ing medium to the blocking seal in the attached unit

against the inflow housing in order to protect the seals in

the attached unit from the medium being separated.

This can be accomplished with sealing grease

.

For this purpose, a grease

press must be used

every

250 operating hours or

every 2 weeks

to introduce

roughly 3 to

5 cm

3

of

grease via the lubricating

nipple

.

The grease should be supplied while the machine is

running to ensure that the entire seal area is filled with

sealing medium. Lubricate the other lubricating nipples

on the geared motor 1x per year.

To safeguard the function of the seal, check the inspec-

tion opening on the bottom of the flange. If sealing me-

dium, water or foreign substances escape here, the

blocking seal is damaged or worn and must be replaced.

If the blocking seal is not replaced, the supply medium

can clog the inspection window over time and also dam-

age the second seal, allowing the medium to damage

the bearing and/or the

gearbox

. It is therefore very im-

portant to regularly check the inspection opening on the

bottom of the flange. No medium should escape from

this opening; otherwise, the blocking seal is damaged

and must be replaced.

Fig. 13-1 Supply with

sealing medium

Inspection

opening

Lubricating

nipple

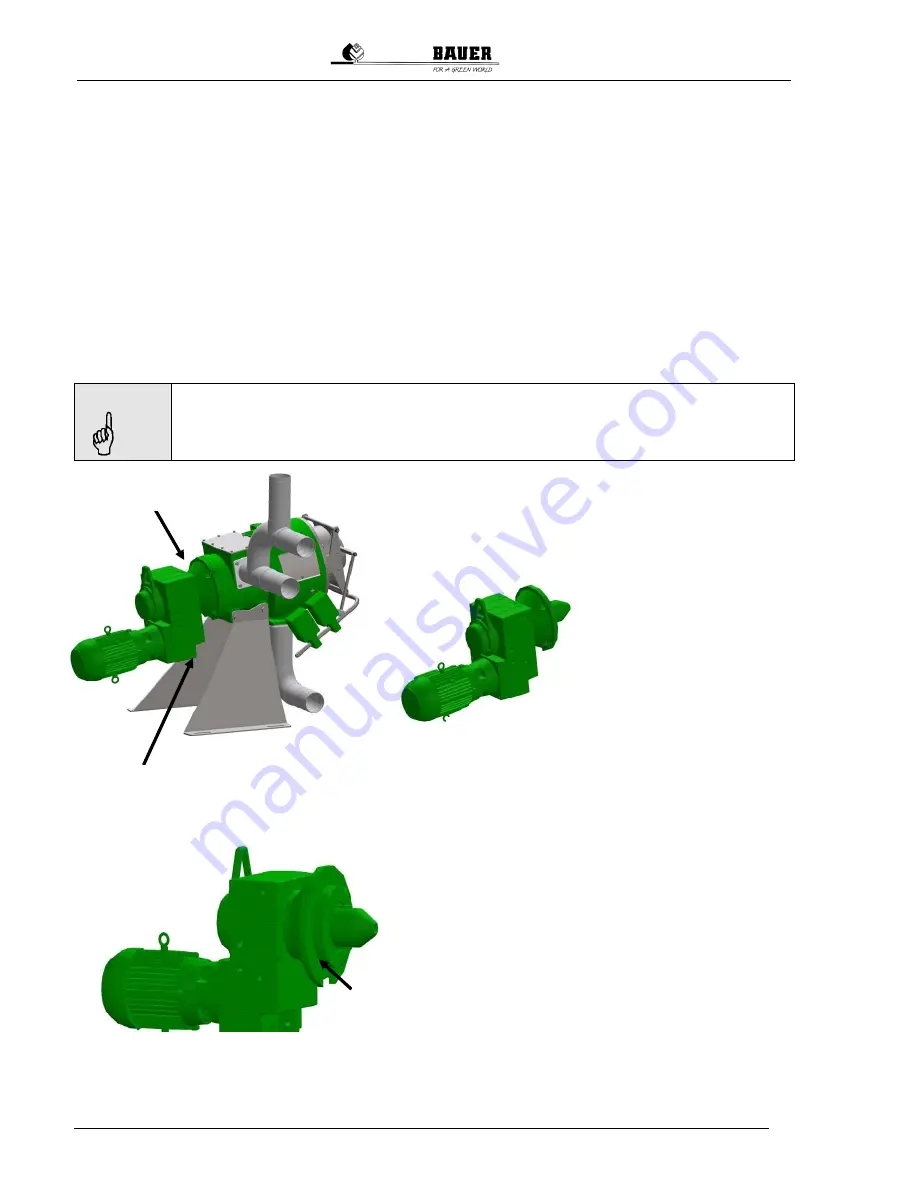

Fig. 13-2 Lubricating nipple

Fig.13-3 Inspection opening

Fig. 13-2 Lubricating nipple