Banner Engineering Corp.

Vibration Monitoring Solutions Kit Quick Start Guide

Page 8

214301 Rev. C

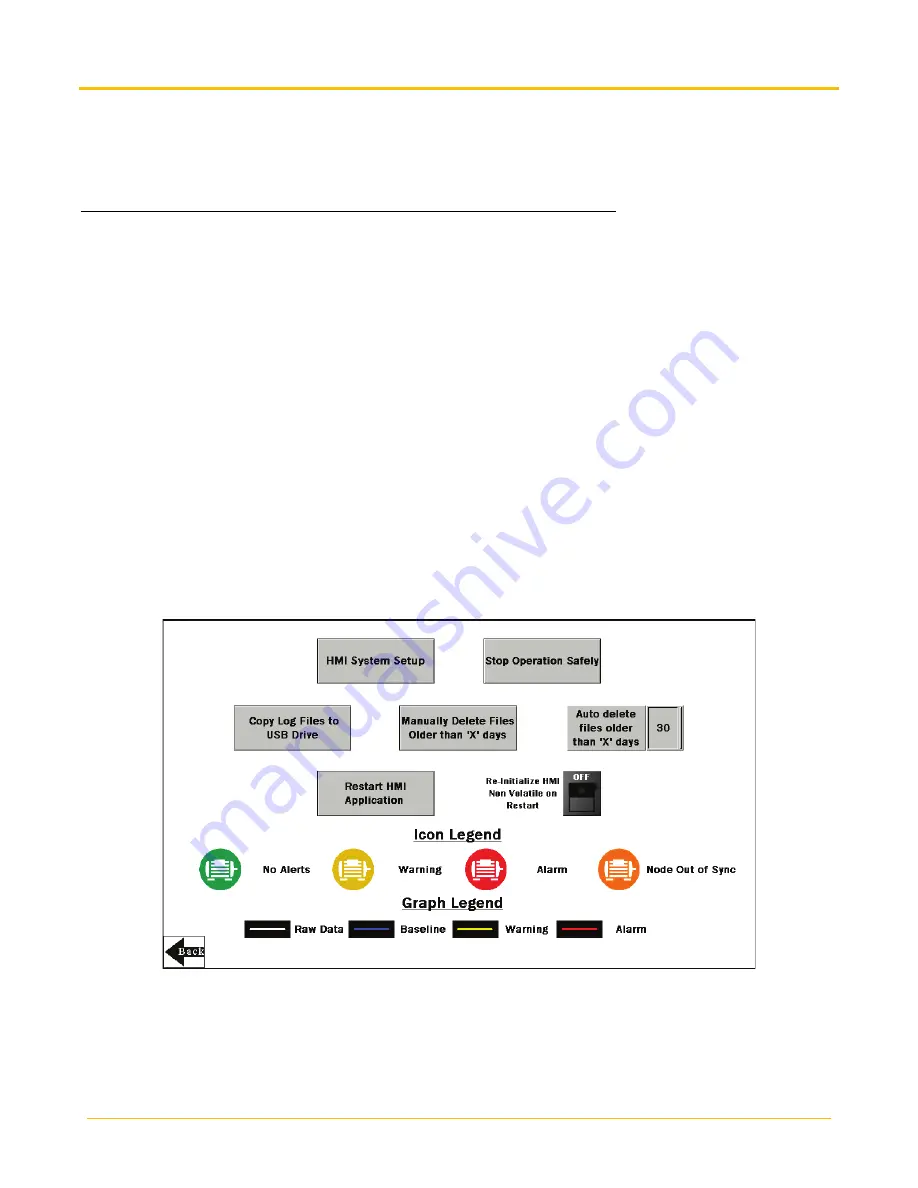

HMI Options Menu Screen

This screen provides some added HMI functionality along with an Icon Legend and a Graph Legend.

HMI System Setup –

Enters HMI Panel Setup. Use for setting Time, Date, and Advanced Options. Entering this

screen will clear any logged data from the graphs but will not clear any data saved to files.

Stop Operation Safely

– Stops HMI operation safely without data corruption before you power off the HMI.

Always use this button prior to powering down to avoid data file corruption. If a “Filed to write logged

data to file” or “Failed to save” message appears this is due to a power during the saving process and will

require the file from the day of the power down to be deleted under the HMI System Setup menu.

The HMI provides data logging of all the raw data, baselines and thresholds. This data is saved to a file every 30

minutes and a new file is generated every day and stored in monthly folders. The HMI has storage for about 45

days of log files. Below are some options for managing and retrieving those files:

Copy Log Files to USB Drive

– Plug a USB drive into the back of the HMI and click here to select the log files or

folders to copy.

Manually Delete Files Older than ‘X’ Days

– Deletes files older than a specified number of days immediately.

Use this option if the HMI is warning about an inability to save data or a lack of storage space. Shortening the

auto delete days parameter may be necessary.

Auto Delete Files Older than ‘X’ Days

–The HMI auto deletes files older than the selected number of days.

Default is 30 days with a maximum of 45 days.

Restart HMI Application

– Restarts the HMI application, which clears all graphed data but retains any saved

logs.

Re-Initialize HMI Non Volatile on Restart

– Flip the switch to ON before restarting the HMI to reinitialize default

settings and labels.