Banner Engineering Corp.

Vibration Monitoring Solutions Kit Quick Start Guide

Page 5

214301 Rev. C

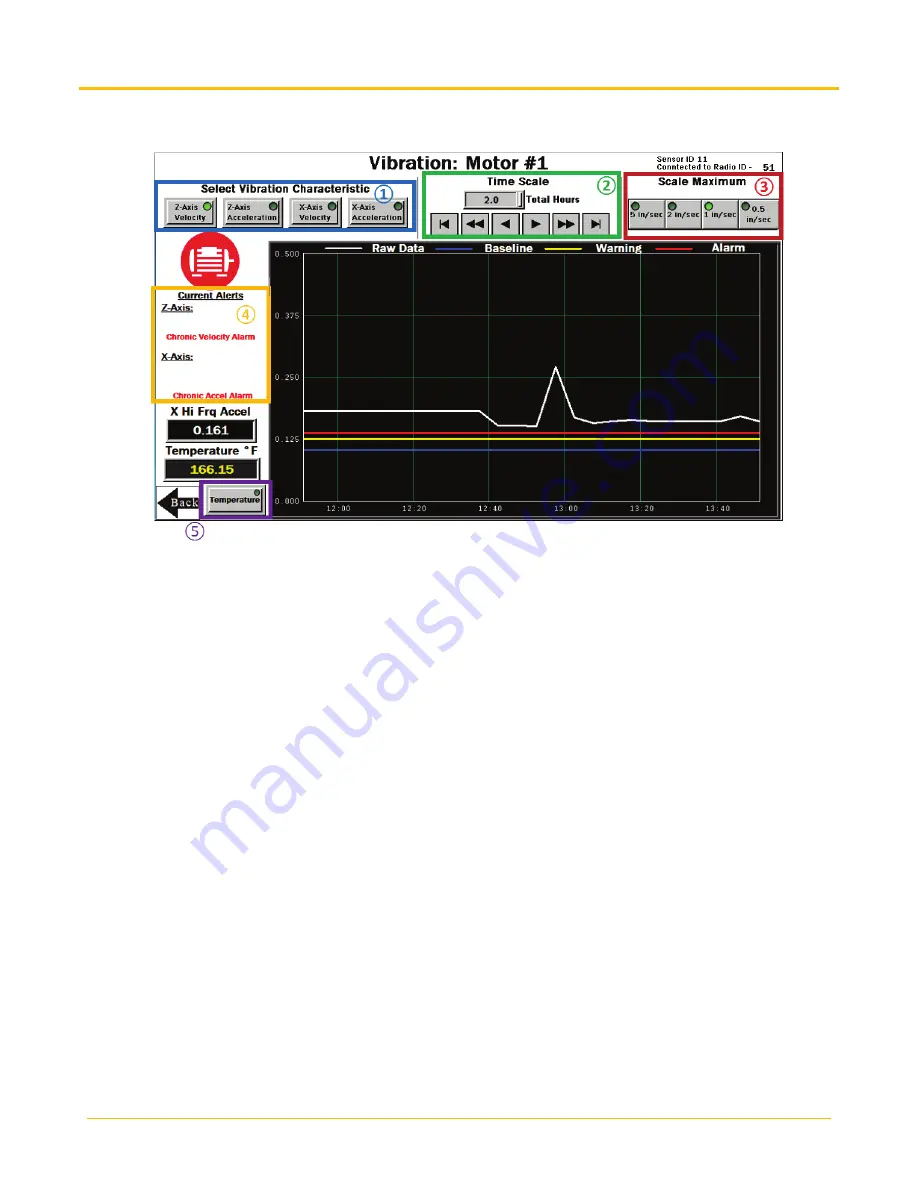

Individual Sensor Status Screen

Selecting a sensor icon opens that sensor’s status screen. Use the

Back

button in the bottom left to return to

the previous screen.

①

- Select the Vibration Characteristic to graph raw data. Options include: Z-Axis Velocity, Z-Axis High

Frequency Acceleration, X-Axis Velocity, and X-Axis High Frequency Acceleration. The bottom left of the screen

shows a real-time readout of the selected characteristic. Velocity is displayed in in/s (mm/s for Vibemetric

versions) and Acceleration is displayed in gs.

Note:

Velocity values of 6.5535 and/or acceleration values of 5.355

indicate a sensor error. The system ignores these data points to avoid affecting the saved baseline or trended

data. The system will not baseline when the raw data values appear as those values. Contact Banner support for

troubleshooting.

②

- Select the

Time Scale

of the graph from 0.1 to 168 total hours (7 days). Use the arrow keys to scroll right

or left to see different periods of the collected data. The graphing data loggers have a fixed number of data

points and if using the DEMO MODE button on the Settings page, then the increased sampling rate reduces the

number of data points available for viewing until those data points have rolled off the end of the timeline.

③

- Select the data

Scale Maximum

. For Acceleration, the range is 0.25g to 5g (g-force) and for Velocity, the

range is 0.5 inches/second to 5 inches/second (10 mm/s to 60 mm/s for metric versions).

④

- The

Current Alerts

section shows any warnings or alarms based on the Axis, Vibration Characteristic, and

type (Chronic or Acute) that the system is detecting. Acute alerts are those crossing the threshold for five

samples in a row (or the user setting on the

Settings

screen) and Chronic alerts are when a 100 point moving

average crosses the thresholds. Only data from an operational asset is used to calculate averages and alerts.

⑤

- Select

Temperature

to view the temperature graph over the selected time period. Directly above the

button is the current temperature of the selected sensor. The readout color is white if it’s nominal, yellow if it’s in

a warning state, and red if it’s in an alarm state. The warning and alarm temperature settings are 158 °F (70 °C)

and 176 °F (80 °C) respectively. A raw temperature value of 327.67 indicates a sensor error. Contact Banner

support for troubleshooting. In the upper right-hand corner of the screen is the Sensor’s Modbus slave ID and

Radio slave ID to which the sensor is attached. This can be useful in finding which radio a sensor is connected

to if the orange Out of Sync status icon appears. Signal quality or battery replacement may be necessary for a

radio that loses connection status.