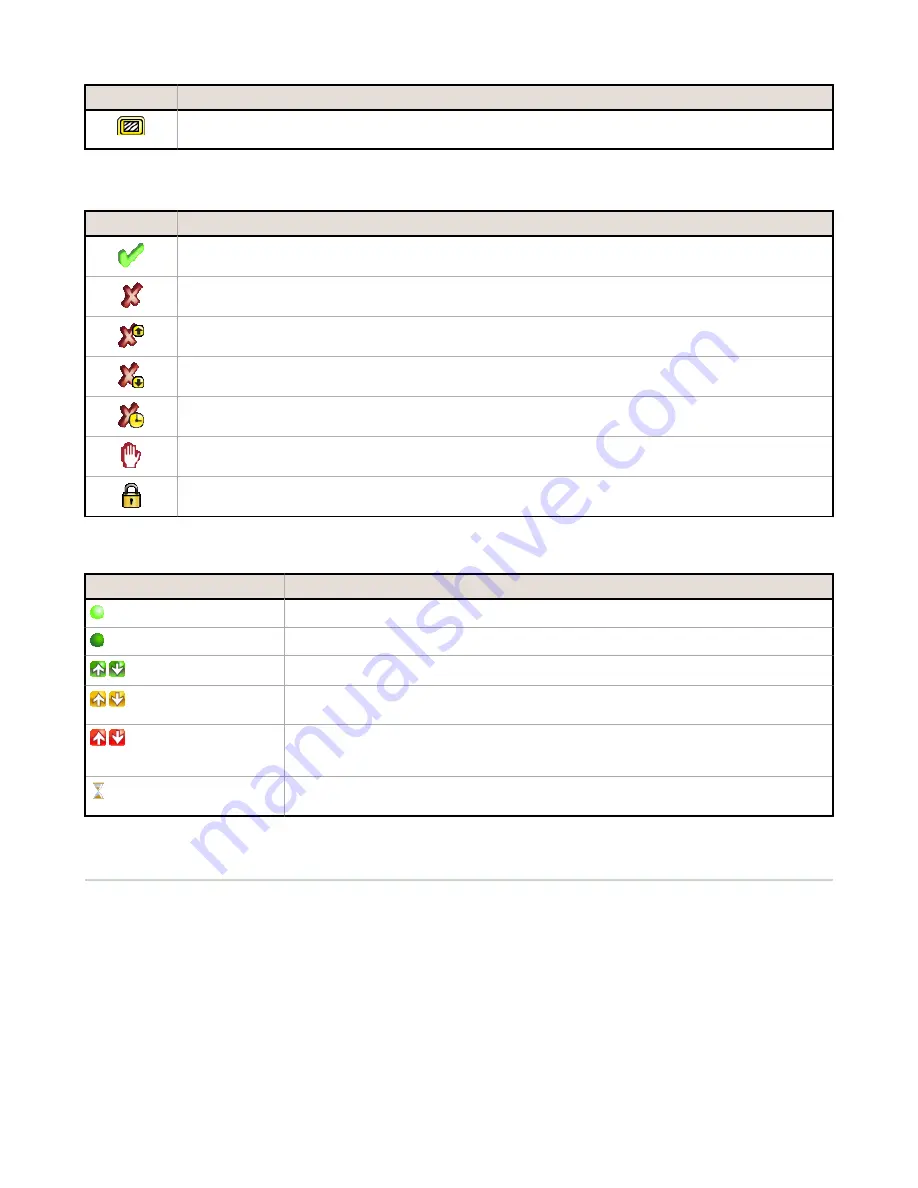

Icon

Description

The Rectangular Mask icon displays on the left side of the screen when a mask is selected. Press to cycle

through and select a Circular, Elliptical, or Rectangular-shaped mask.

Display Icons

Icon

Description

The Inspection Passed icon is located in the upper-left of the screen, and indicates that the last inspection

passed its test conditions.

One of the possible Inspection Failed icons located in the upper-left of the screen, it indicates that the last

inspection failed.

One of the possible Sensor Failed icons located in the Inspection Statistic table, it indicates that the

sensor failed because the number of objects exceeded the test count.

One of the possible Sensor Failed icons located in the Inspection Statistic table, it indicates that the

sensor failed because there were fewer objects than specified by the test count.

One of the possible Sensor Failed icons located in the Inspection Statistic table, it indicates that the

sensor failed because the inspection timed out.

One of the possible Inspection Failed icons located in the upper-left of the screen, it indicates that the

sensor is in fail hold mode.

The Sensor Locked icon is located in the upper-left of the screen, and indicates that the sensor is in a

locked state. If no icon is displayed, the sensor is unlocked.

Communications Log Icons

Icon

Description

Port opened.

Port closed.

Indicates that the command has been processed without errors.

Indicates that the incoming entry is stalled (no new bytes), or end-of-frame delimiter

was not received, or client is not reading data on ethernet.

If the response frame contains an error or is dropped, the log entry icons for the request

and the response frames will be colored red, and the displayed error count will

increment by one.

If the command takes a long time to process, the last long entry will change to an

hourglass (for example, during trigger of long inspections).

Acquiring a Good Image

The iVu Series sensor needs to capture a good image of each part to ensure that it correctly passes good parts and fails

bad parts.

1. Go to Main Menu > Imager > Auto Exposure to run the Auto Exposure routine.

2. Check the lighting.

•

Make sure that the lighting is constant and consistent (unchanging over time, no shadows or hot spots).

•

Capture the shape and form of the target object with lighting that optimizes its contrast and separates it

from the background. Depending on the target, this may mean the integral ring light is not the best choice

and other Banner lights should be considered.

•

Adjust the mounting angle to provide the clearest image of the part features you are monitoring. The

mounting bracket lets you easily position and adjust the sensor on your line.

3. If needed, go to Main Menu > Imager > Auto Exposure to run the Auto Exposure routine a second time or

adjust Gain and Exposure manually:

•

Main Menu > Imager > Gain

iVu Plus TG Gen2 Series Sensor

P/N 178442 Rev. B

www.bannerengineering.com - Tel: +1-763-544-3164

7