Quick Start Guide

Introduction

The iVu Plus TG Gen2 Series Sensor is used to monitor labels, parts, and packaging for type, size, orientation, shape, and

location. The sensor has an integrated or remote color touch screen display making installation, setup and configuration

easy without requiring a PC.

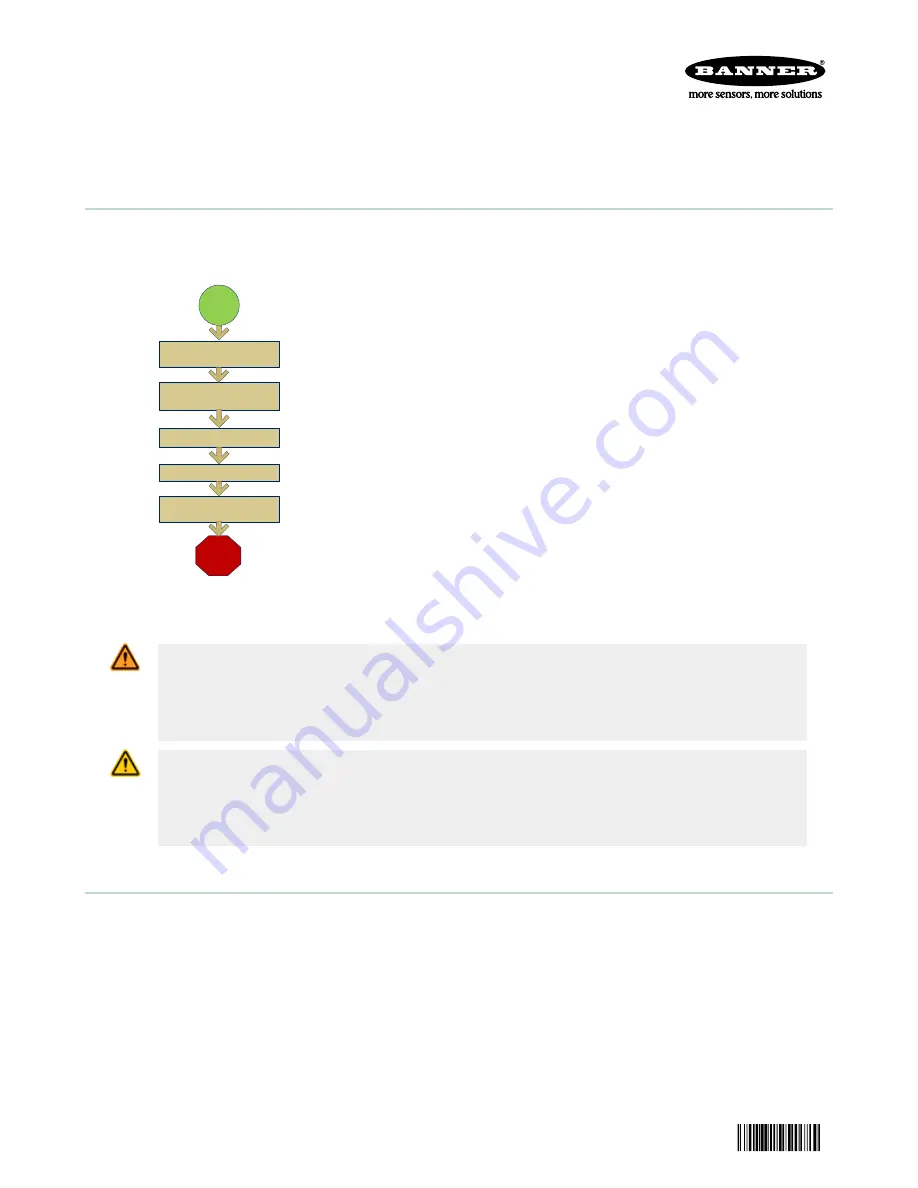

Finish

Set Sensor Parameters

Start

Install and Connect the

Sensor

Initial Boot into Demo Mode

Select Sensor Type

Acquire A Good Image

Quick Start Overview

This guide is designed to help you set up and install the iVu Plus TG. It

provides an overview of the sensor and illustrates how to set up the sensor

to inspect a label, part, or packaging. The flow chart to the left provides an

overview of the process.

Use of this document assumes familiarity with pertinent industry standards

and practices.

For complete information on programming, performance, troubleshooting,

dimensions, and accessories, please refer to the documentation listed below.

This documentation is available on the Product CD or at

. Search for the part number to view the

documentation.

•

iVu Plus TG Gen2 with Integrated Display (datasheet; P/N 179044)

•

iVu Plus TG Gen2 with Remote Display (datasheet; P/N 179045)

•

iVu Plus TG Gen2 Instruction Manual (P/N 179042)

•

iVu Plus Industrial Ethernet User's Guide (P/N B_3095133)

In addition, the sensor includes integrated Help.

WARNING: Not To Be Used for Personnel Protection

Never use this device as a sensing device for personnel protection. Doing so could lead to

serious injury or death. This device does not include the self-checking redundant circuitry necessary

to allow its use in personnel safety applications. A sensor failure or malfunction can cause either an

energized or de-energized sensor output condition.

CAUTION: Electrostatic Discharge

Avoid the damage that electrostatic discharge (ESD) can cause to the Sensor.

Always use a proven method for preventing electrostatic discharge when installing a lens or attaching a

cable.

Installing and Connecting the Sensor

The iVu Plus TG sensor requires a bracket for mounting. Three brackets are available from Banner. The brackets allow the

sensor to be mounted either perpendicular to the part or at an adjustable angle.

Thread three M4 x 4mm screws through the bracket into the mounting holes in the bottom of the sensor. Tighten all three

screws.

iVu Plus TG

Gen2

Series Sensor

Original Document

178442 Rev. B

9 September 2014

178442