Installation

Electrical Installation

23

Machine

Max Amps Breaker

Wire Size

Max Amps Breaker

Wire Size

HP-60, 3PH

8

15

14ga / 2.5mm

4

15

14ga / 2.5mm

HP-60, 1PH

13.6

15

14ga / 2.5mm

200-240V

380-480V

Note: For single phase (1

N

) operation,

connect input power to L1 and L2, leaving

the L3 terminal open.

Note:

Do not use phase adders (roto-phase)

on inverter driven equipment!

Note:

Wire sizes shown are for copper,

THHN, 90 conductor per NEC article 310

(USA).

The machine should be connected to an

individual branch circuit not shared with

lighting or other equipment.

Because this is a vibrating machine, the use

of SO cable or similar, with a twist-lock

plug, to connect the machine to main power

is recommended. A shielded liquid tight or

approved flexible conduit with proper

conductor of correct size installed in

accordance with National Electric Code

(USA) or other applicable codes is also

acceptable. The connection must be made

by a qualified electrician using the wiring

diagram provided with the machine. See

the Electrical Connection data Chart for

correct wire sizes.

Use wire sizes indicated in the chart for runs

up to 50 feet (15m). Use next larger size for

runs of 50 to 100 feet (15-30m). Use 2 sizes

larger for runs greater than 100 feet (30m).

For personal safety and for proper

operation, the machine must be grounded

in accordance with state and local codes

and in the USA in accordance with the

National Electric Code, article 250-96.

The ground connection must be to a proven

earth ground, not to conduit or water pipes.

Do not connect the ground to the neutral

(N) leg at the terminal strip (if so equipped).

If a DELTA supply system is used, the high

leg should be connected to L3, since

control voltage is derived from L1 and L2.

Insure that the control transformer taps are

connected in accordance with the incoming

line voltage. Verify connections as shown

on the schematic with each machine.

Summary of Contents for HP series

Page 2: ......

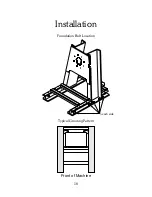

Page 19: ...Front of Machine 18 Installation Foundation Bolt Location Typical Grouting Pattern 5 each side...

Page 38: ......