5

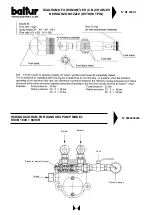

FASTENING THE BURNER TO THE BOILER

The burner must be applied to the boiler’s iron plate (with a heat protection flange inserted in-between), where the stud

bolts given as standard accessories have already been fitted in accordance with the plate drilling.

It is advisable to electrically weld the stud bolts to the internal part of the plate to avoid extracting them together with the

unit’s locking nuts, should be burner be disassembled.

If the plate is not supplied with heat insulation, it is necessary to insert a heat protection flange at least 10 mm. thick

between the plate and the boiler.

Ensure that the combustion head enters the furnace to the extent specified by the boiler manufacturer.

The burner can be supplied with a normal head or a long head on request.

ELECTRICAL CONNECTIONS

It is advisable to make all connections with flexible electric wire.

The electric lines should be at an adequate distance from hot parts.

Make sure that the electric line to which the unit will be connected has frequency and voltage ratings suitable for the

burner.

Check that the main line, the relevant switch with fuses (essential) and the current limited are capable of with standing

the maximum current absorbed by the burner.

For details, refer to the specific electric diagram for each single burner.

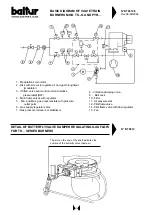

FASTENING THE BURNER TO THE GAS PIPELINE

When the burner has been fastened to the boiler, keeping in mind that the burner head should penetrate the combustion

chamber to the extent specified by the boiler manufacturer, proceed with connecting it to the gas pipeline.

It is indispensable to install a double flanged fitting on the pipeline, as near as possible to the burner, to allow for easy

disassembling of the burner and/or opening of the boiler door.

Before closing this fitting, it is indispensable to carry out a purge of the air contained in the pipeline.

As a precaution, special care should be taken and doors and windows should be opened.

The pipeline must be perfectly hermetic and it should be tested before the burner’s general inspection.

DETAILS ON IGNITION OF MIXED BURNERS

We advise that ignition with liquid fuel be carried out first because, in this case, delivery is conditioned by the nozzle

utilized, whereas methane gas delivery can be varied as one likes by operating the relative flow regulator.

Summary of Contents for TS 0 GN

Page 2: ......

Page 47: ......

Page 48: ......

Page 49: ......

Page 50: ......

Page 51: ......

Page 52: ......

Page 53: ......

Page 54: ......

Page 55: ......

Page 56: ......

Page 57: ......

Page 58: ......

Page 59: ......

Page 60: ......

Page 61: ......

Page 62: ......

Page 63: ......

Page 64: ......

Page 65: ......

Page 66: ......

Page 67: ......

Page 68: ......

Page 69: ......

Page 70: ......

Page 71: ......

Page 72: ......

Page 73: ......

Page 74: ......

Page 75: ......

Page 76: ......

Page 77: ......

Page 78: ......

Page 79: ......

Page 80: ......

Page 81: ......

Page 82: ......

Page 83: ......

Page 84: ......

Page 85: ......

Page 86: ......

Page 87: ......

Page 88: ......

Page 89: ......

Page 90: ......

Page 91: ......

Page 92: ......

Page 93: ......

Page 94: ......

Page 95: ......