www.balluff.com

3

italiano

1

Informazioni sulle presenti istruzioni

1.1 Validità 5

1.2 Documenti di riferimento

1.3 Simboli e segni utilizzati

1.4 Significato delle avvertenze

1.5 Abbreviazioni 5

2

2.1 Uso conforme

2.2 Utilizzo improprio ragionevolmente prevedibile

2.3 Indicazioni di sicurezza generali

3

Fornitura, trasporto e magazzinaggio

3.1 Fornitura 7

3.2 Trasporto 7

3.3 Condizioni di magazzinaggio

4

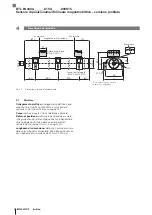

4.1 Struttura 8

4.2 Funzionamento 9

4.3 Elementi di comando e visualizzazione

4.4 Targhetta di identificazione

5

5.1 Montaggio 10

5.2 Collegamento elettrico

5.3 Schermatura e posa dei cavi

6

Messa in funzione e funzionamento

6.2 Funzionamento 13

6.3 Avvertenze per il funzionamento

6.4 Manutenzione 13

7

Configurazione con il Balluff Engineering Tool (BET)

7.1 Balluff Engineering Tool (BET)

7.3 Possibilità di configurazione

8

8.1 Riparazione 16

8.2 Smaltimento 16

9

9.2 Campo di rilevamento/Campo di misura

9.3 Caratteristiche elettriche

9.5 Uscita/Interfaccia 18

9.6 Materiale 18

9.7 Caratteristiche meccaniche

9.8 Autorizzazioni e contrassegni

BTL PA0400- _ _ _ _ -C15A _ _ _ _ -000S15

Sensore di posizionamento lineare magnetostrittivo – versione profilata

Summary of Contents for BTL PA0400 Series

Page 2: ...www balluff com...

Page 3: ...BTL PA0400 ____ C15A____ 000S15 Betriebsanleitung deutsch...

Page 4: ...www balluff com...

Page 23: ...BTL PA0400 ____ C15A____ 000S15 User s Guide english...

Page 24: ...www balluff com...

Page 43: ...BTL PA0400 ____ C15A____ 000S15 Notice d utilisation fran ais...

Page 44: ...www balluff com...

Page 63: ...BTL PA0400 ____ C15A____ 000S15 Manuale d uso italiano...

Page 64: ...www balluff com...

Page 83: ...BTL PA0400 ____ C15A____ 000S15 Manual de instrucciones espa ol...

Page 84: ...www balluff com...

Page 103: ...BTL PA0400 ____ C15A____ 000S15 Manual de Instru es portugu s...

Page 104: ...www balluff com...

Page 123: ...BTL PA0400 ____ C15A____ 000S15...

Page 124: ...www balluff com...

Page 126: ...4 10 19 10 1 19 10 2 19 11 20 BTL PA0400 ____ C15A____ 000S15...

Page 128: ...6 2 1 BTL PLC Balluff 2 2 2 3 2 BTL PA0400 ____ C15A____ 000S15...

Page 129: ...www balluff com 7 3 1 3 2 3 3 17 3 BTL PA0400 ____ C15A____ 000S15...

Page 134: ...12 6 1 1 2 3 BTL BTL 6 BTL PA0400 ____ C15A____ 000S15...

Page 138: ...16 8 1 8 2 www balluff com 8 BTL PA0400 ____ C15A____ 000S15...

Page 143: ...BTL PA0400 ____ C15A____ 000S15...

Page 144: ...www balluff com...

Page 146: ...4 10 19 10 1 19 10 2 19 11 20 BTL PA0400 ____ C15A____ 000S15...

Page 148: ...6 2 1 BTL SPS Balluff 2 2 2 3 2 BTL PA0400 ____ C15A____ 000S15...

Page 149: ...www balluff com 7 3 1 3 2 3 3 17 3 BTL PA0400 ____ C15A____ 000S15...

Page 154: ...12 6 1 1 2 3 BTL BTL 6 BTL PA0400 ____ C15A____ 000S15...

Page 158: ...16 8 1 8 2 www balluff com 8 BTL PA0400 ____ C15A____ 000S15...

Page 163: ...BTL PA0400 ____ C15A____ 000S15...

Page 164: ...www balluff com...

Page 166: ...4 10 19 10 1 19 10 2 19 11 20 BTL PA0400 ____ C15A____ 000S15...

Page 168: ...6 2 1 BTL PLC Balluff 2 2 2 3 2 BTL PA0400 ____ C15A____ 000S15...

Page 169: ...www balluff com 7 3 1 3 2 3 3 17 3 BTL PA0400 ____ C15A____ 000S15...

Page 174: ...12 6 1 1 2 3 BTL BTL 6 BTL PA0400 ____ C15A____ 000S15...

Page 178: ...16 8 1 Balluff Balluff 8 2 www balluff com 8 BTL PA0400 ____ C15A____ 000S15...

Page 183: ...BTL PA0400 ____ C15A____ 000S15...

Page 184: ...www balluff com...

Page 186: ...4 10 19 10 1 19 10 2 19 11 20 BTL PA0400 ____ C15A____ 000S15...

Page 188: ...6 2 1 BTL Balluff 2 2 2 3 2 BTL PA0400 ____ C15A____ 000S15...

Page 189: ...www balluff com 7 3 1 3 2 3 3 17 3 BTL PA0400 ____ C15A____ 000S15...

Page 194: ...12 6 1 1 2 3 BTL BTL 6 BTL PA0400 ____ C15A____ 000S15...

Page 198: ...16 8 1 Balluff 8 2 www balluff com 8 BTL PA0400 ____ C15A____ 000S15...

Page 203: ......