Chapter 4. Operation

4.1 Introduction

See

Chapter 2, “Installation”

, and

Chapter 3, “Initial Setup”

,

to prepare your

PanaFlow Z1G/Z2G Process Gas Flowmeter

system for operation. When the meter is ready to take

measurements, proceed with this chapter. The following

specific topics are discussed:

• “Powering Up” below

• “The PanaFlow Z1G/Z2G Process Gas Flowmeter LCD

Display” on page 35

• “The Optional PanaView Display” on page 36

• “Taking Measurements” on page 37

Note:

All inputs and outputs of the PanaFlow Z1G/Z2G

Process Gas Flowmeter are calibrated at the factory prior to

shipment. If it becomes necessary to recalibrate any of the

inputs and/or outputs, consult the factory for instructions.

WARNING!

To ensure the safe operation of the

PanaFlow

Z1G/Z2G Process Gas Flowmeter

, it must

be installed and operated as described in

this manual. In addition, be sure to follow

all applicable local safety codes and

regulations for the installation of electrical

equipment.

4.2 Powering up

Because the

PanaFlow Z1G/Z2G Process Gas Flowmeter

does

not have an ON/OFF switch, it will power up as soon as the

connected power source is energized.

WARNING!

For compliance with the European Union’s

Low Voltage Directive, this unit requires an

external power disconnect device such as

a switch or circuit breaker. The disconnect

device must be marked as such, clearly

visible, directly accessible, and located within

1.8 m (6 ft) of the meter.

There are three methods for obtaining readings from the

PanaFlow Z1G/Z2G Process Gas Flowmeter

:

• Built-in

PanaFlow Z1G/Z2G Process Gas Flowmeter

LCD

display

• PanaView

software installed on a personal computer

• External analog device to read the

PanaFlow Z1G/Z2G

Process Gas Flowmeter

analog output

At least one of the above display options must be installed

in order to obtain flow rate readings from the meter.

Immediately upon power up, the

software version

display

appears. Then, the meter performs a series of internal

checks, which take about 45 seconds, prior to displaying the

flow rate data

(see

“Initial Power On Screens” on page 23

).

Note:

If the PanaFlow Z1G/Z2G Process Gas Flowmeter fails

any of the internal checks, try disconnecting the power and

then re-powering the unit. If the meter continues to fail any

of the internal checks, contact the factory for assistance.

After successfully performing the internal checks, the

PanaFlow Z1G/Z2G Process Gas Flowmeter

begins taking

measurements and the software version display is

replaced by a measurement mode display. Proceed to the

appropriate section for instructions on using the LCD display

and the PanaView display option.

Note:

As a minimum, the system and pipe parameters

for each installed channel must be entered before the

PanaFlow Z1G/Z2G Process Gas Flowmeter can display

valid data. Refer to Chapter 3, “Initial Setup”, for specific

instructions.

4.3 The PanaFlow Z1G/Z2G process

gas flowmeter LCD display

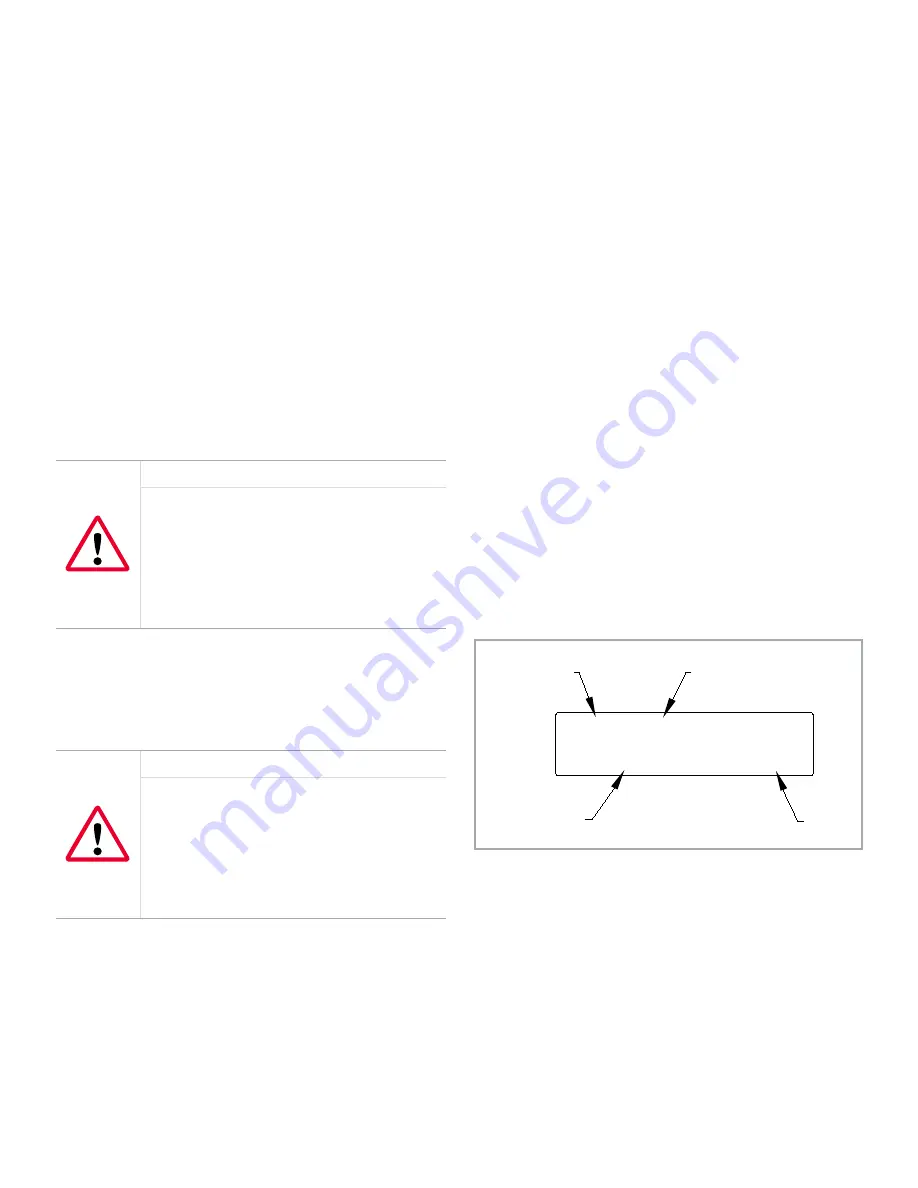

The components of the

PanaFlow Z1G/Z2G Process Gas

Flowmeter

LCD display are shown in

Figure 17

below, along

with a typical mass flow rate readout.

VEL

Ch1 MDOT

0.00

LB/SEC

Parameter

Channel #

Units

Flow Rate

Figure 17: A typical LCD flow rate display

As shown in

Figure 17

above, the

PanaFlow Z1G/Z2G Process

Gas Flowmeter

display screen includes the following

information:

• Channel Number

• Flow Parameter

• Units of Measure

• Flow Rate Value

However, the items in this list may be reprogrammed to

display a variety of alternative choices (see

“Programming

the LCD Display” on page 37

).

23

Summary of Contents for PanaFlow Z1G

Page 1: ...PanaFlow Z1G Z2G User s manual 910 321 Rev A...

Page 2: ...ii...

Page 4: ...no content intended for this page iv...

Page 9: ...no content intended for this page 1...

Page 21: ...Figure 12 Remote mount electronics transducer and preamplifier wiring ref dwg 702 731 732 13...

Page 28: ...no content intended for this page 20...

Page 30: ...no content intended for this page 22...

Page 38: ...no content intended for this page 30...

Page 40: ...no content intended for this page 32...

Page 43: ...Table 13 Service record cont Date Description of service Performed by 35...