Assembly

18

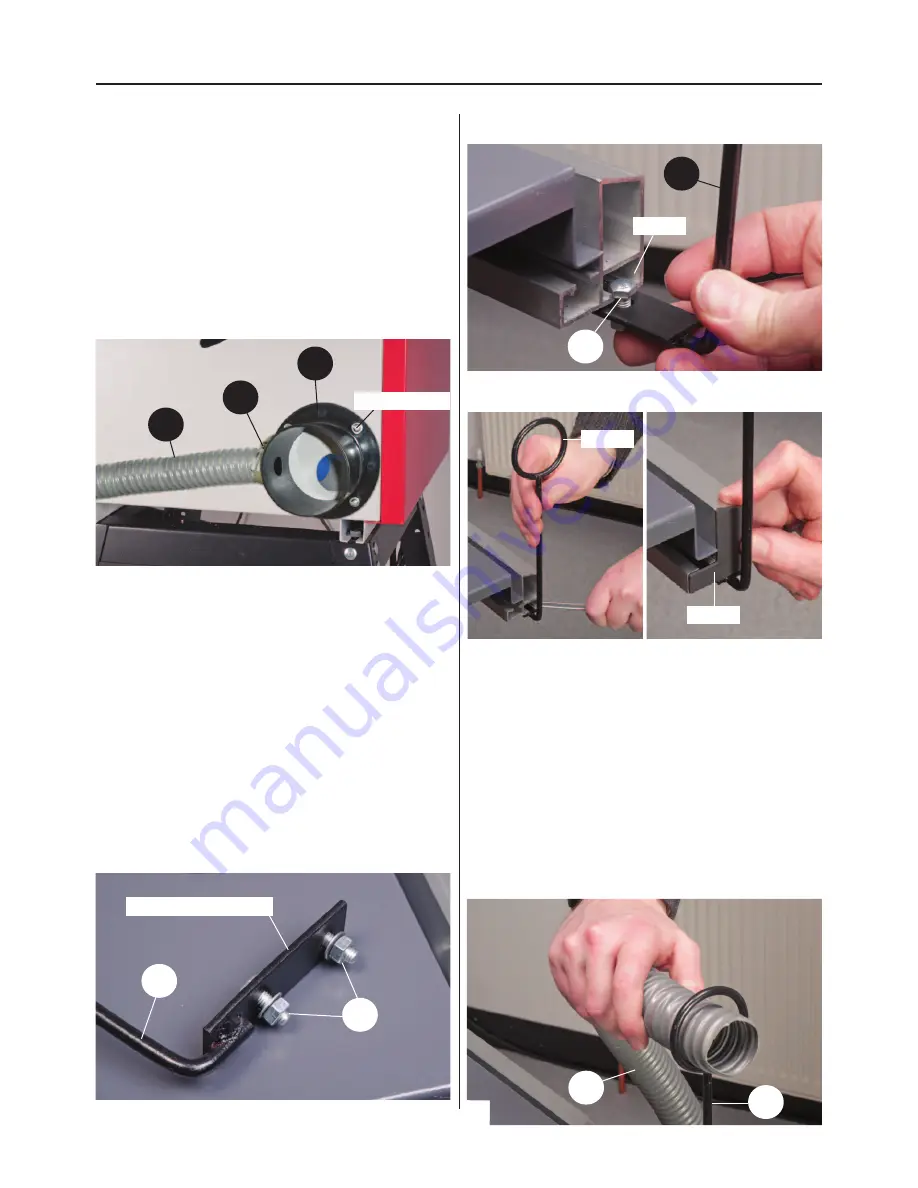

3). Line up the holes in the extraction moulding (C),

with the threaded holes to the rear of the saw table

(A) and secure in place with the Phillips screw and

washers, see fig 53.

4). Slide the remaining hose clip over one end of

the 30mm hose and fit the hose over the table saws

30mm dust extraction moulding outlet and nip tight,

see fig 53.

Fig 53

C

B

G2

Phillips screws

Code 508212 Only

5). Locate 30mm hose support bracket (P) and two

M6x16 Hex bolts, washers and nuts (O4). Remove the

plastic cover from the end of the rear extension table

support arm (N) and place safely aside. Remove the

nuts and washers from the Hex bolts, introduce the

bolts through the pre-drilled holes in the support

bracket plate (P) and replace the washers and nuts,

see fig 54.

NOTE: Leave a gap between the Hex bolt head

and support bracket plate for the next step.

Fig 55

Fig 54

Fig 56-57

O4

P

Support bracket plate

6). Turn the bracket support (P) so the ring is facing

upwards, line up the two Hex bolts (O4) with the

‘T’ slot and slide the support bracket assembly on.

Leave sufficant space to replace the plastic cover.

Tighten the Hex nuts to sercure the assembly,

see figs 55-56. Replace the cover to the end of the

support arm, see fig 57.

7). Slot the flexible hose (B) through support ring (P),

see fig 58 and secure it to the extraction moulding

(C) as described in step 3.

Fig 58

P

O4

‘T’ slot

Ring

Cover

B

P

Summary of Contents for Hobby series TS-250M

Page 28: ...Parts Breakdown List 28...

Page 30: ...Parts Breakdown List 30...