71

AvMap G7 Farmnavigator – User Manual

-‘USB Cable/ Video in’ (g7 Ezy, p/n: K2CYFS0600) or cable USB / Video in / Ethernet’ (G7

Plus, P/N: K2CYFS1000).

Perform the following procedure:

1.

Copy the update file from a PC to

USB stick;

2. Connect USB cable to the G7 Farmnavigator bracket;

3. Insert USB stick into the USB connector of the supplied cable;

4. Turn G7 Farmnavigator on, the device starts in update mode;

5. Tap “UPDATE NOW” to install the update;

6. Tap “CONTINUE” and wait for the program to start;

7. The update is now completed and the USB stick can be dismissed.

6.2 Video camera

G7 Farmnavigator allows you to connect an external, analogic video camera. There are no settings

to be performed on the software.

6.2.1 Type of supported cameras

G7 Farmnavigator supports analogic cameras with PAL o NTFS format.

The video camera must be provided with a male RCA connector. Power to the video camera must

be supplied externally to G7 Farmnavigator. IP and USB camera are not supported. Power must be

supplied externally.

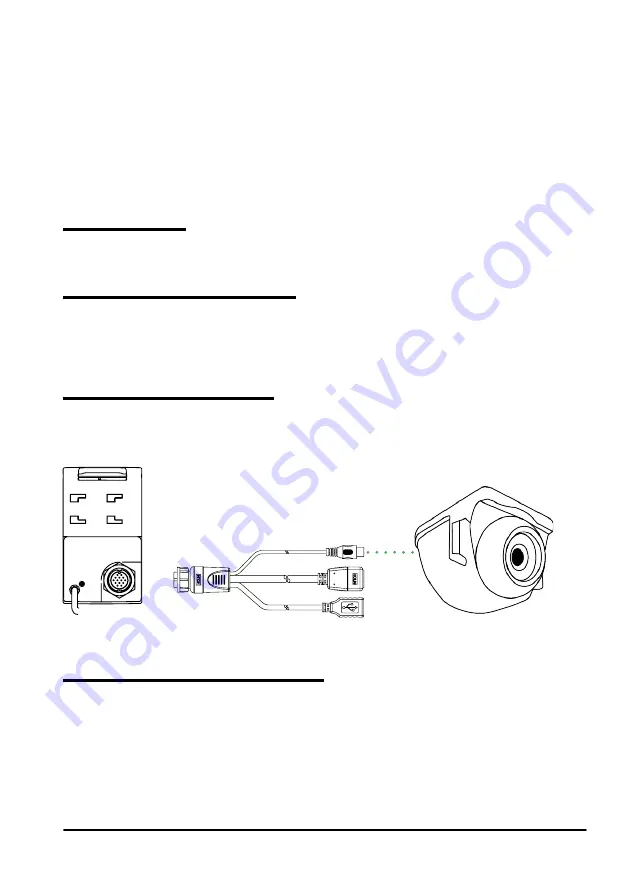

6.2.2 Connect a video camera

It is possible to connect a video camera to G7 Farmnavigator via the ‘USB cable/Video in’ (G7 Ezy,

P/N: K2CYFS0600) or ‘USB cable / Video in /Ethernet’ (G7 Plus, P/N: K2CYFS1000). The cable is

provided with an analog RCA female video input.

Figure 6.2.a How to connect a video camera to G7 Farmnavigator

6.2.3 Display mode for Video camera

When the camera is properly connected to G7 Farmnavigator, the video camera icon will be

automatically activated on the main page of your job.

-Tap the camera icon displayed on the main page of your job to switch to video mode.

Summary of Contents for G7 Farmnavigator

Page 1: ...USER MANUAL Updated to 3 10 xR software version where x indicates all 3 10 software versions ...

Page 2: ......

Page 4: ......

Page 79: ......