EN-1320

OPERATION AND INSTALLATION MANUAL

HOLD THE BLADES NEAR BLADE SHANK AT TURNING, NEVER AT TIP.

3 Safety the cam 27 after adjustment with the securing screw.

NOTE:

It is possible to check when the circuit is energized, using power supply (max. 12V) and a suitable lamp

connected to connector pins 3 and 4 (figure 12-20).

e) All screws used for adjusting should be secured with suitable paint.

(4)

Maximum reverse output adjustment

(only for propeller governor LUN7815.02)

a) Verify, that rod “Sv” 65 is disconnected from the gate “Sv”. If not, loose and remove nut and remove

the pin. Then disconnect the rod from its gate (figure 12-17).

b) Fix the loosen rod “Sv” 65 using lock wire to the governor such way, that it will not be reduced in its

movement later during adjustment.

c) Adjust maximum reverse power according to engine operational manual.

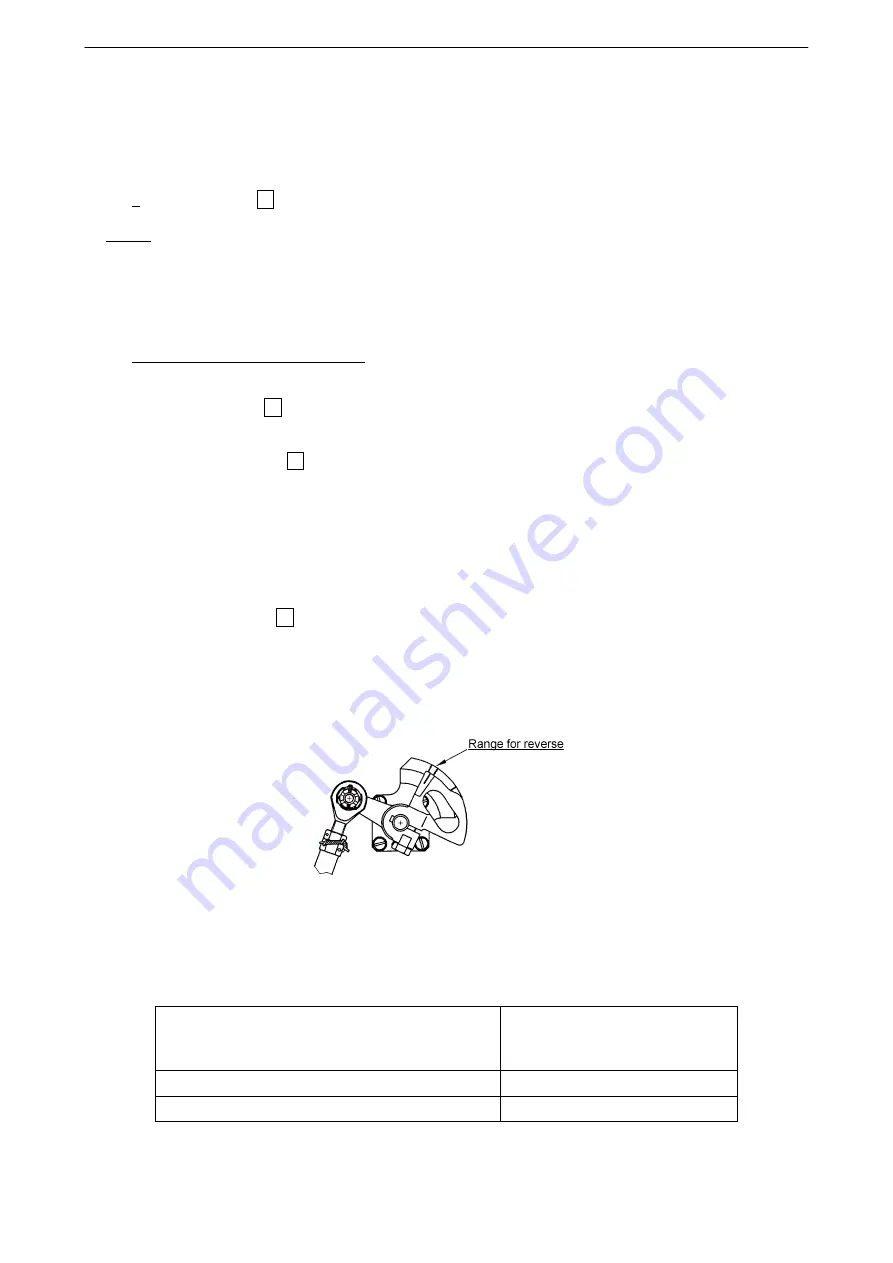

d) Place the engine condition lever to maximum reverse position after reverse power adjustment.

Guideline on the cam lever should align with reverse range zone (figure 12-21). If not, adjust according

to the engine operational manual.

e) Connect the rod "Sv" 65, tighten the nut on the pin and verify adjustment of the joint linkage on the

scale according to this section.

f) After basic adjustment verification according to this section, secure the nut with a cotter pin.

Figure 12-21 Reverse output adjustment - scale

WARNING:

THE MAXIMUM REVERSE POWER OF THE ENGINE CAN BE RESTRICTED (DECREASED) FOR

SPECIFIC PROPELLER MODEL ! REFER TO TABLE 12-1.

Propeller model

Maximum engine reverse power

at H=0m ISA

AV-725-1-E-C-F-R(W)/CFR230-433

200kW

Table 12-1 Maximum permitted reverse power

61-10-20

PROPELLER CONTROL SYSTEM

(Installation With Jihostroj LUN-Series Governor)

Page 12-19

2017-10-06