EN-1320

OPERATION AND INSTALLATION MANUAL

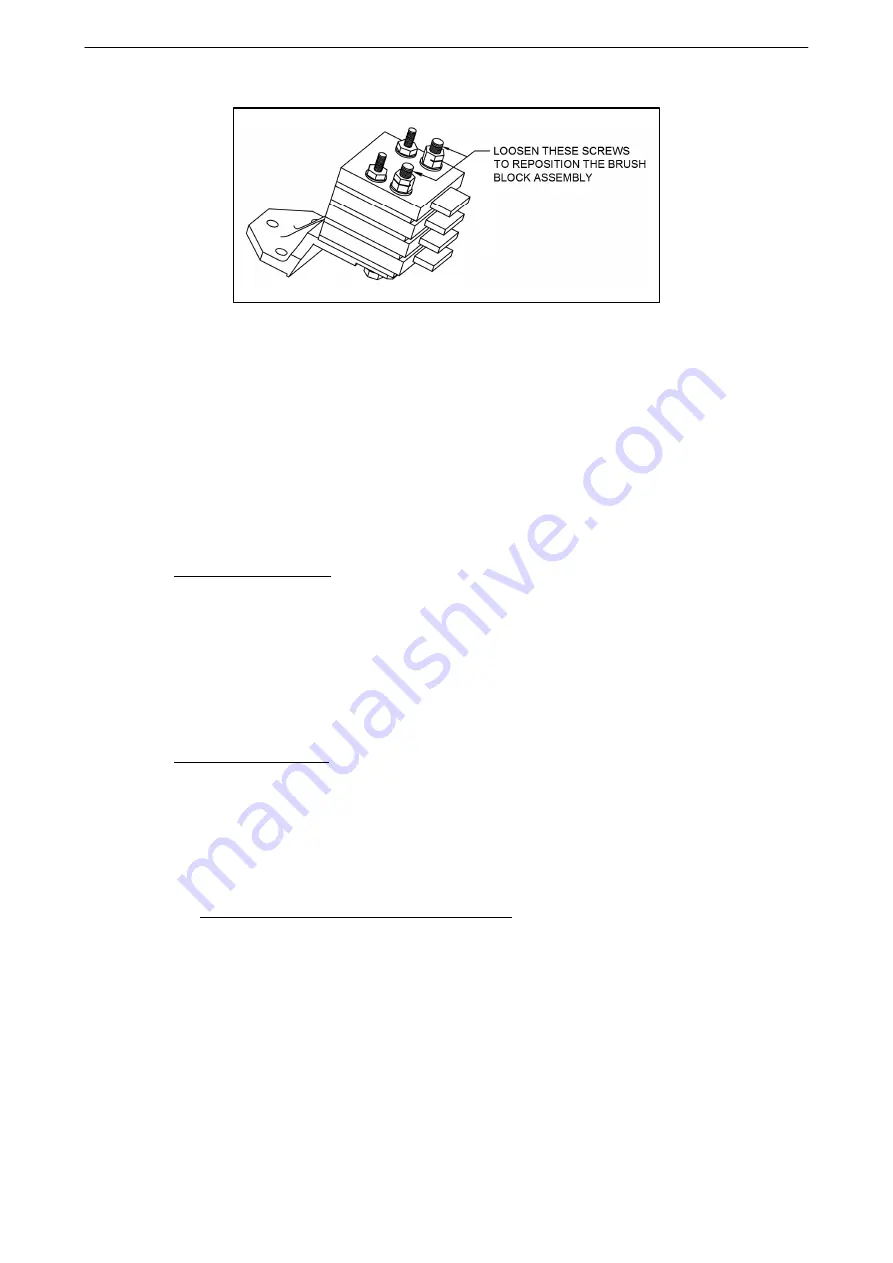

FIGURE 5-17

5.14 Adjusting

Mechanical low and high pitch stops, reverse and feathering, are adjusted during manufacture,

according to the requirement of the aircraft/engine combination. Low pitch can only be adjusted

via the beta-setup. Feathering can be adjusted by turning the check nuts. The reverse pitch stop

cannot be changed in the field.

On the models ending in -R(W), feather, low pitch and reverse cannot be changed in the field.

a) Models Ending in -R(G)

Set the low pitch blade angle with the unfeathering pump and turn the beta tube in or out.

Refer to figure 5-10.

•

Turning in: lower pitch

•

Turning out: higher pitch

The beta tube is secured by the screw AN3H-13A and the stop nut MS20364-1032A.

Put washer AN 960-10 on both sides. Finally bring the blades into the start lock.

b) Models Ending in -R(P)

CAUTION: LOW PITCH STOP HAS TO BE ADJUSTED IN COMPLIANCE WITH THE

DESCRIPTION OF THE AIRPLANE MANUFACTURER, FOR EXAMPLE ON

PT6A-( ) ENGINE, TORQUE VERSUS RPM, DEPENDING ON DENSITY

ALTITUDE AND TEMPERATURE, E.G. 650 FTLBS AT 1800 RPM.

ADDITIONAL THE MIN. PROPELLER RPM MUST BE REACHED AT GROUND

IDLE, SEE FLIGHT MANUAL.

1) AV-725 and AV-844 Propellers Ending in -R(P)

Low pitch can be adjusted by turning the low pitch adjusting nuts in or out. Therefore

the cover caps, springs and the spring guides must be removed from the hub. Follow

the procedure above in this chapter.

•

Turning in: higher pitch

•

Turning out: lower pitch

CAUTION: ALL STOPNUTS MUST HAVE THE SAME SETTING TO EACH OTHER,

OTHERWISE THE PITCH CHANGE MECHANISM WILL BE DAMAGED

BECAUSE OF WOBBLING OF THE BETA RING.

61-10-20

INSTALLATION AND OPERATION INSTRUCTION

Page 5-13

2017-10-06