Page 26

IronHorse GSDA-DP-D DC Drives Accessory User Manual – 1st Ed. Rev. A – 11/11/2019

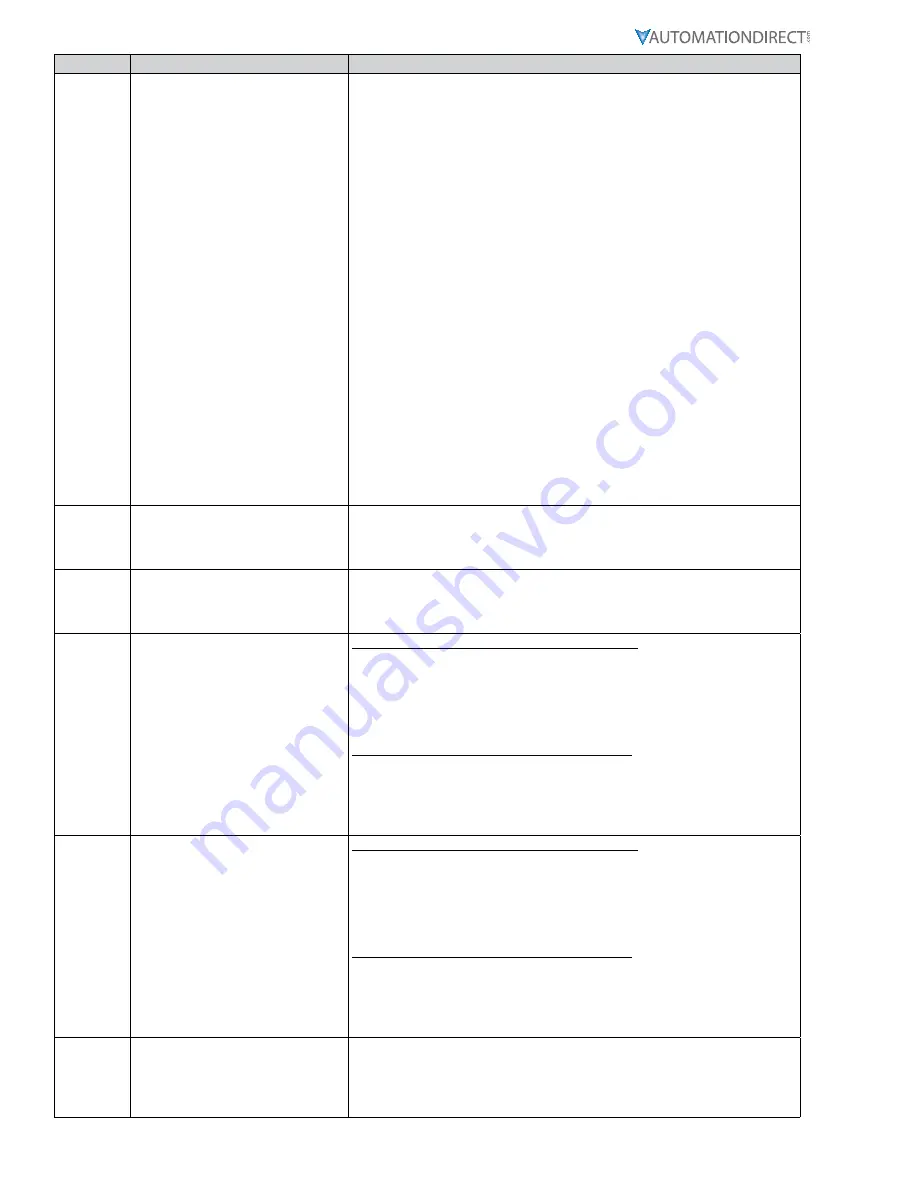

Parameter

Parameter Name

Description

22

Motor Control Method

This Parameter controls two behaviors in the GSDA-DP-D, Low-Speed “Gain-

Tracking”, and Ultra-Low-Speed Control Mode (“gearbox” mode). When set to

a value of 1 (or 3), this parameter automatically (and proportionally) reduces

the “gain” of the PID values when the Target Speed (in RPMs) is less than

200. This greatly increases the overall stability at low speeds in applications

that require a very wide range of Target Speeds, without having to unduly

compromise control responsiveness at higher speeds. When set to a value of 2

(or 3), this Parameter adjusts the speed-control characteristics of the GSDA-

DP-D to enhance the smoothness of speed control when in a situation where

the “tach pickup” must be installed on the “low speed side” of a very slowly

turning gear-motor output shaft. A rule of thumb would probably be that you

may consider enabling this Mode if that shaft is turning less than 10 RPM,

and the pickup produces less than 10 Pulses Per Revolution (PPR). Use this

Mode only if speed stability can not be achieved by adjusting the PID settings

(Parameters 26 – 28).

• Mode 0: Disabled

Both Low-Speed-Gain-Tracking and Ultra-Low-Speed Control Mode are

Defeated.

• Mode 1: Low-Speed-Gain-Tracking (Only) Enabled

Low-Speed-Gain-Tracking is Enabled, Ultra-Low-Speed Control Mode is

Defeated.

• Mode 2: Ultra-Low-Speed Control Mode (Only) Enabled

Low-Speed-Gain-Tracking is Defeated, Ultra-Low-Speed Control Mode is

Enabled.

• Mode 3: Low-Speed-Gain-Tracking and Ultra-Low-Speed Control Mode

(Both) Enabled

Both Low-Speed-Gain-Tracking and Ultra-Low-Speed Control Mode are

Enabled.

23

Acceleration Setting

This Parameter determines how fast the GSDA-DP-D will accelerate toward the

displayed target setting. This Parameter is set in engineering units of change

per second, such as RPM, GPM, or feet per second. In Follower Mode, this

Parameter is set in RPM units.

24

Deceleration Setting

This Parameter determines how fast the GSDA-DP-D will decelerate toward the

displayed target setting. This Parameter is set in engineering units of change

per second, such as RPM, GPM, or feet per second. In Follower Mode, this

Parameter is set in RPM units.

26

Closed-Loop Proportional (P) Gain

/ Open-Loop Output Percentage

Maximum

Closed-Loop Operation (Item 22 set to a value < 32)

In Closed-Loop operation, the Proportional Gain is the first of three Items

which define the responsiveness of the control with respect to how fast it

responds to changing loads. Because the Accu-Set plus controls are true

velocity-form PID control, the higher the P Gain, the more aggressively the unit

will respond to a change in load or target speed. See the “Basic Operating

Instructions” section of the manual for more details.

Open-Loop Operation (Item 22 set to a value = 32)

In Open-Loop operation, this Item sets the percentage (from 0% to 100.0%) of

the voltage supplied across the LO (P1-5) and HI (P1-3) terminals that will be

Output across the LO (P1-5) and WP (P1-4) terminals when the Target “Speed”

setting is equal to (or less than) the Display Minimum (Item 20). See the “Basic

Operating Instructions” section of the manual for more details.

27

Closed-Loop Integral (I) Gain /

Open-Loop Output Percentage

maximum

Closed-Loop Operation (Item 22 set to a value < 32)

The Integral Gain is the second of two Items which define the responsiveness

of the control with respect to how fast it responds to changing loads. The

higher the I Gain, the more aggressively the unit will drive the load. However,

it will sometimes be necessary to decrease the I Gain and/or increase the P

Gain to prevent unwanted oscillation and instabilities. See the “Basic Operating

Instructions” section of the manual for more details.

Open-Loop Operation (Item 22 set to a value = 32)

In Open-Loop operation, this Item sets the percentage (from 0% to 100.0%) of

the voltage supplied across the LO (P1-5) and HI (P1-3) terminals that will be

Output across the LO (P1-5) and WP (P1-4) terminals when the Target “Speed”

setting is equal to (or greater than) the Display Maximum (Item 21). See the

“Basic Operating Instructions” section of the manual for more details.

28

Derivative (D) Gain

(Unused in Open-Loop operation)

The Derivative Gain is the third of the three Parameters which define the

responsiveness of the control with respect to how fast it responds to changing

loads. Although most applications will run fine with the D Gain set to zero,

sometimes adding a little “D” will help minimize overshoot and undershoot.

See the “Basic Operating Instructions” section of the manual for more details.